Tear Testing: An Essential Procedure in Engineering and Material Science

In this article, we will delve into various aspects of materials testing, focusing on tear testing and tensile strength tests, particularly in the context of fabrics. The conversation will explore the definitions, methods, standards, and applications of these tests, highlighting their essential roles in evaluating material properties. Differences between tear strength and tensile strength, specific procedures like Fabric Tensile Strength Test, and the intricate relationships between different mechanical properties will be thoroughly examined, providing a understanding of these concepts.

In the following text, you will find a summary of the topics that will be addressed in this article.

What is the Tear testing?

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under conditions that might lead to tearing. The force required to initiate and propagate the tear, as well as the manner in which the tear develops, provides critical insights into the material’s structural integrity and durability.

Tear testing is commonly applied to fabrics, plastics, paper, and other thin materials. The data derived from these tests is vital for understanding material behavior in various applications and industries, including automotive, packaging, textiles, and aerospace.

Different methodologies and standards guide tear testing, such as the Elmendorf Tear Test or the Trouser Tear Test, with specific protocols depending on the material type and intended use. The results from tear testing help engineers and designers select appropriate materials and design products that meet specific performance and safety requirements.

What is the importance of Tear testing?

Tear testing holds a significant position in the field of materials science and engineering, as it provides essential insights into a material’s tear resistance. Here’s an overview of why tear testing is so important:

- Understanding Material Behavior: Tear testing helps in characterizing how a material responds to forces that can lead to tearing. By understanding this aspect of a material’s performance, manufacturers can predict how it might behave in real-world applications where tearing might occur.

- Quality Control: In industries like textiles, packaging, and automotive, the resistance to tearing is often a critical quality parameter. Tear testing provides a standardized means of assessing this property, ensuring that materials meet the necessary quality standards.

- Product Design and Material Selection: By knowing a material’s tear resistance, engineers and designers can make informed decisions about which materials to use in specific products. This ensures that the materials are suited to the stresses they will encounter in actual use, enhancing product reliability and longevity.

- Safety Considerations: In some applications, a material’s resistance to tearing is directly linked to safety. For example, in parachutes or airbags, a failure in tear resistance can lead to catastrophic consequences. Tear testing provides the necessary data to ensure that materials used in these applications are fit for purpose.

- Compliance with Regulations: Many industries have specific regulations governing material properties. Tear testing enables manufacturers to demonstrate compliance with these regulations, ensuring that the products are legally and ethically sound.

- Economic Efficiency: Selecting materials without proper understanding of their tear characteristics could lead to premature failure and waste. Tear testing helps in reducing material waste by aiding in the selection of the right materials for the right applications, consequently saving costs in the long run.

- Consumer Confidence: Products that have been tested for tear resistance and meet relevant standards can give consumers confidence in their quality and durability. This can enhance brand reputation and trust.

- Environmental Impact: By choosing materials that are appropriate for their intended use, and thus less likely to fail, manufacturers contribute to sustainability by reducing waste and the need for replacements.

Tear testing is more than a simple laboratory procedure; it’s a critical aspect of materials characterization that influences design, safety, compliance, and even the economic and environmental impact of products. It bridges the gap between theoretical understanding and practical application, ensuring that materials and products function effectively and efficiently in their intended applications. Without tear testing, there would be significant challenges in ensuring the integrity, reliability, and safety of many products that we use daily.

What are the advantages of using the Tear testing?

Tear testing offers several advantages that make it an essential tool in materials characterization and quality control. Here’s a breakdown of some of the key benefits:

- Quantitative Analysis: Tear testing provides numerical values for tear resistance, allowing for an objective comparison between different materials or treatments. This quantitative data can be used for quality control, material selection, and design optimization.

- Industry Standards Compliance: By adhering to recognized testing standards such as ASTM or ISO, tear testing ensures that the results are consistent and comparable across different manufacturers and labs. This standardization is vital for regulatory compliance and international trade.

- Informed Material Selection: The information derived from tear testing enables engineers and designers to choose materials that are well-suited for specific applications, improving the performance and longevity of the products.

- Enhanced Safety: For products where tear resistance is crucial for safety (such as seat belts, parachutes, or industrial fabrics), tear testing helps ensure that the materials meet the necessary safety standards, thereby minimizing the risk of failure.

- Quality Control and Assurance: Tear testing can be incorporated into routine quality control processes, providing ongoing assurance that materials are being produced to the required specifications. This helps in maintaining brand reputation and customer trust.

- Cost-Effective: By identifying materials that are most likely to perform well in specific applications, tear testing can reduce the risk of product failure and the associated costs of recalls, replacements, and warranty claims.

- Customizable to Material Type: Different types of tear tests can be employed depending on the material and application, allowing for a tailored approach that provides the most relevant information.

- Predictive Insights: Tear testing offers predictive insights into how a material will behave under real-world conditions. This enables proactive design adjustments to prevent problems before they occur, rather than reacting to failures after the fact.

- Environmental Stewardship: By facilitating the selection of materials that are fit for purpose, tear testing contributes to sustainability by reducing waste and energy consumption associated with product failures and replacements.

- Supports Research and Development: Tear testing plays a vital role in research and development, aiding in the formulation of new materials or the improvement of existing ones. It provides essential data that drives innovation and technological advancement.

Tear testing is not just a measure of a material’s resistance to tearing; it’s a multifaceted tool that informs various aspects of materials science, engineering, and product development. Its advantages span quality control, safety, cost-efficiency, environmental responsibility, and more, making it an indispensable part of modern manufacturing and engineering. Whether used to comply with industry standards, guide material selection, or foster innovation, tear testing adds significant value to the materials and products it evaluates.

Types of tear testing

Certainly! Tear testing is a fundamental method used to evaluate the ability of a material to resist tearing. Here are some of the common types of tear testing, along with a brief explanation of each test and the associated standards:

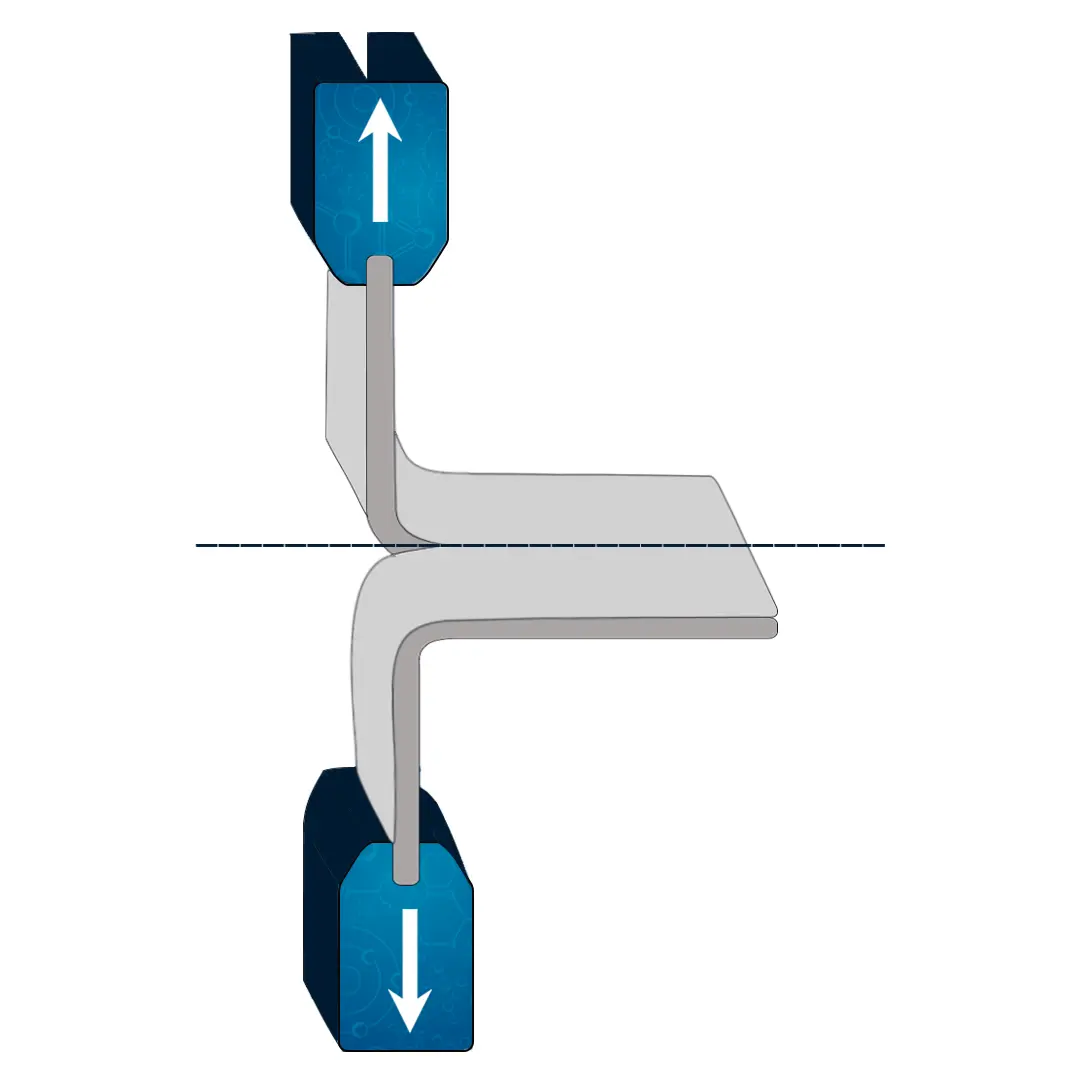

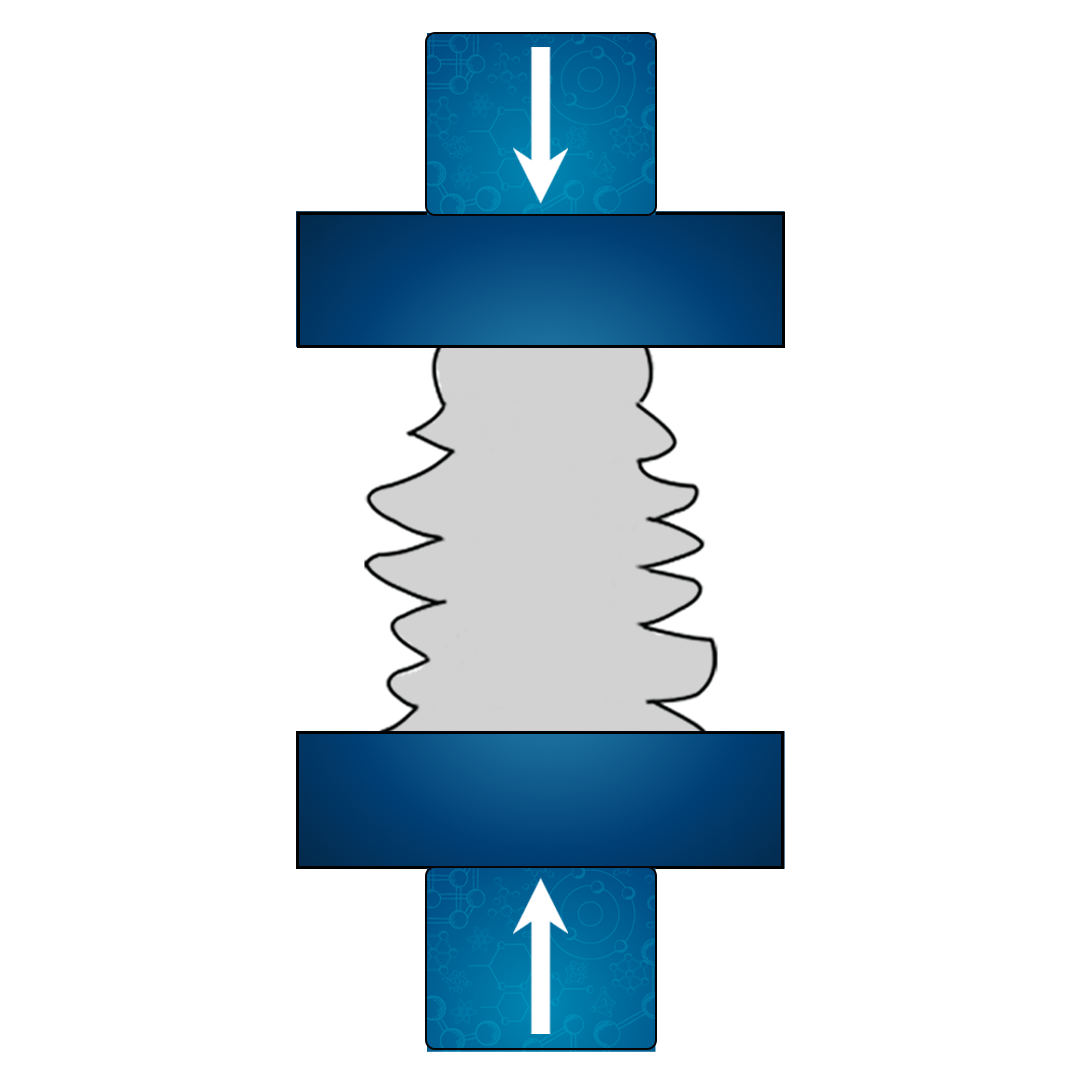

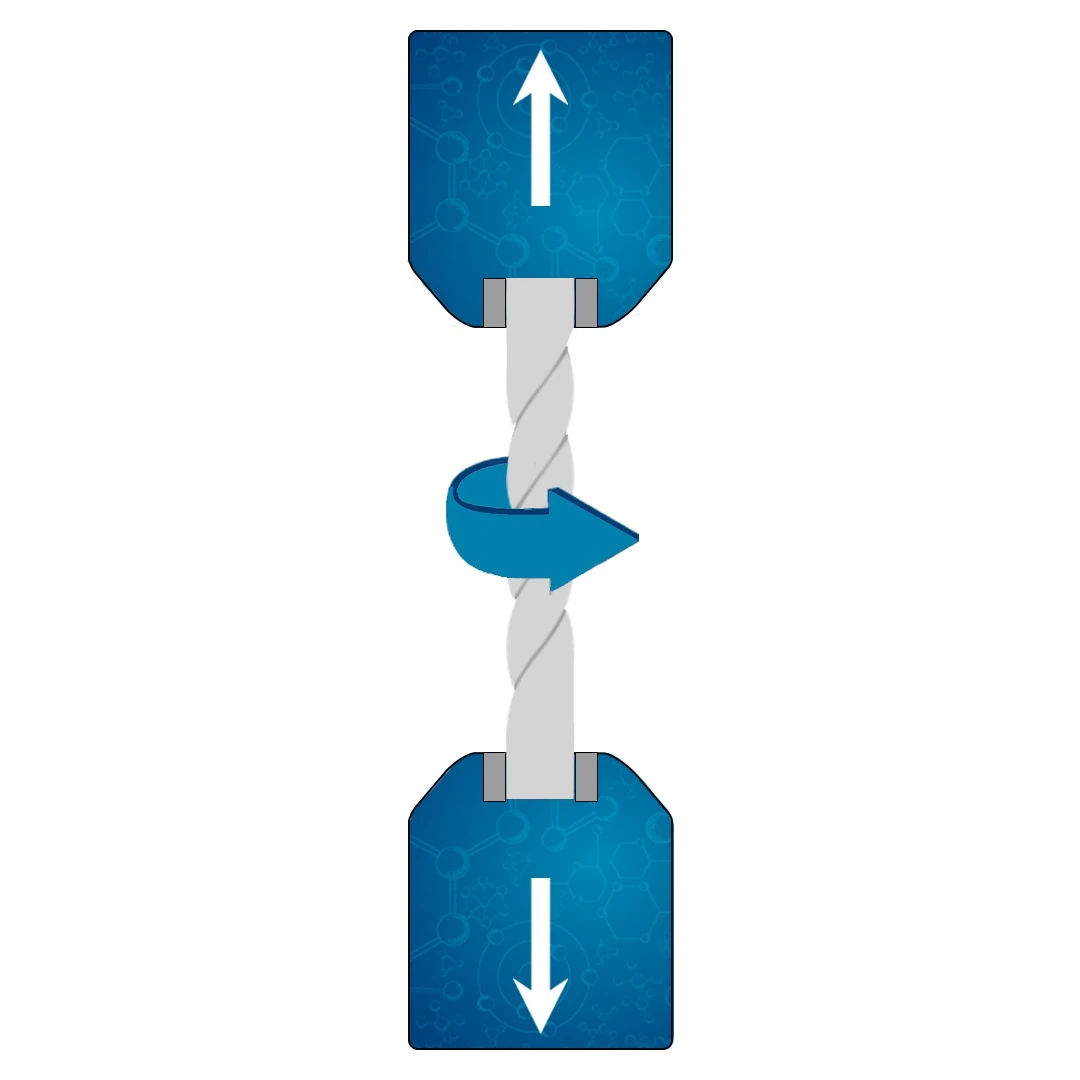

- Trouser Tear (Single Rip) Test: This method involves cutting the specimen into a trouser-like shape, creating a small tear, and then pulling the “legs” apart to propagate the tear. Standards: ASTM D1938 (for plastics), ISO 34-1 (for rubber).

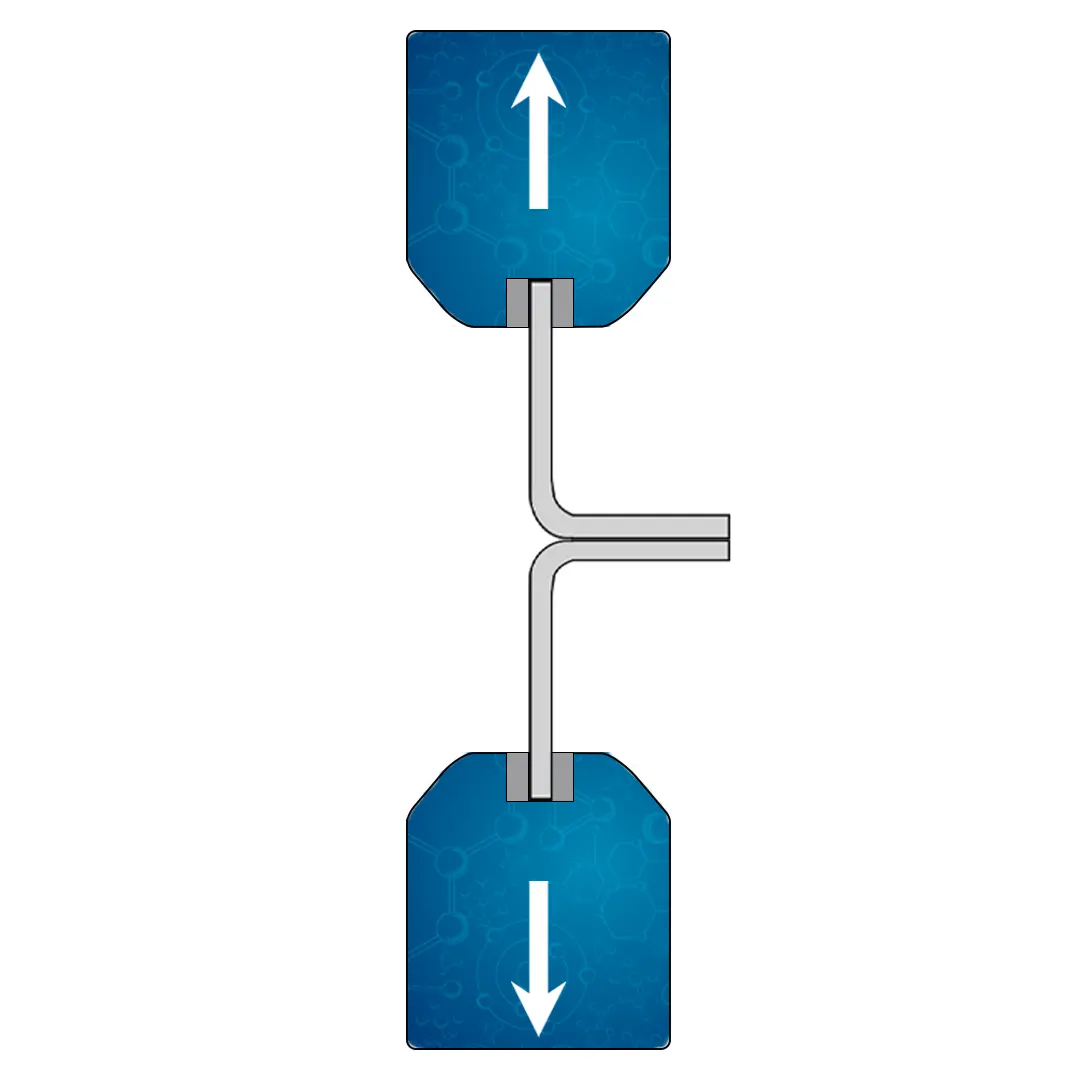

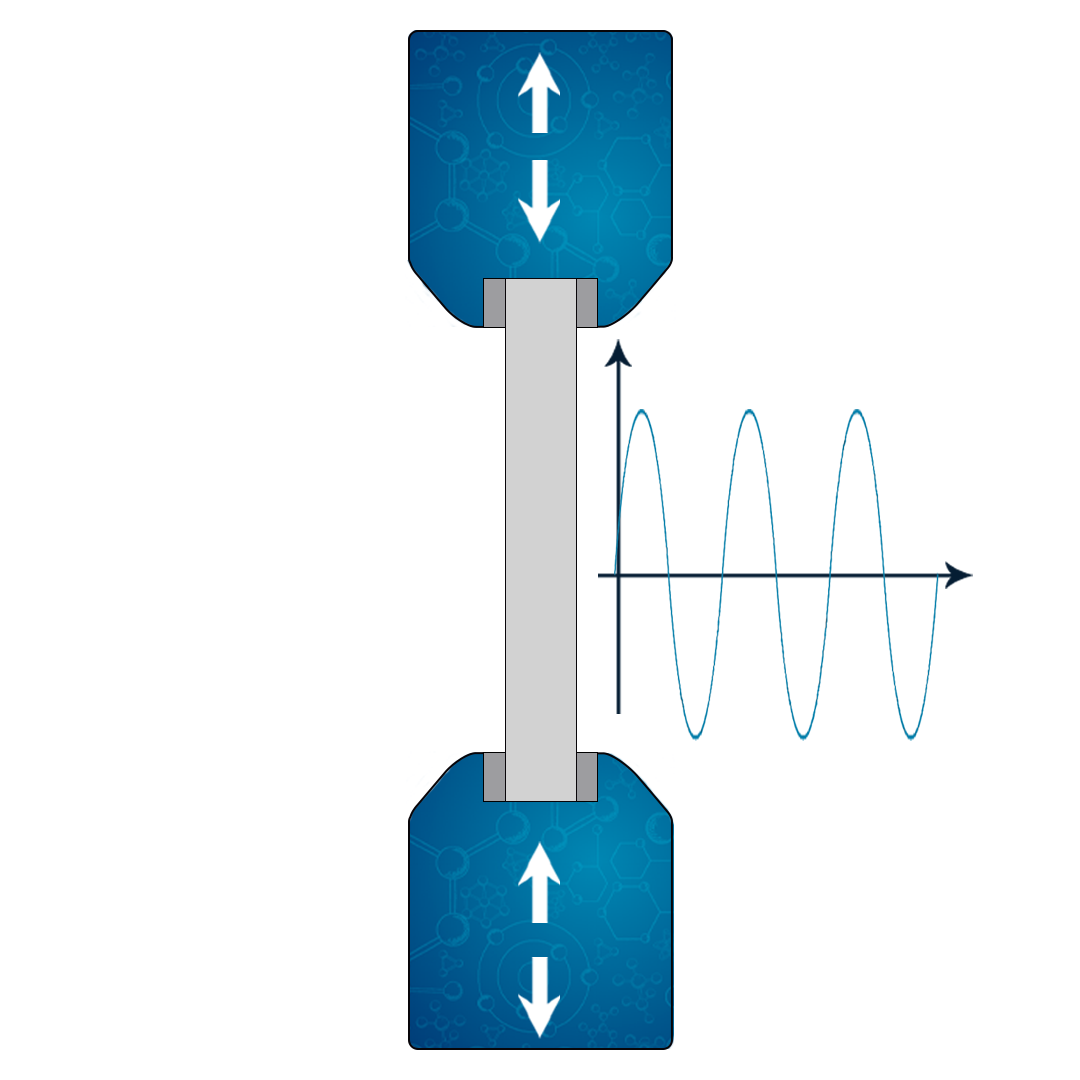

- Tongue Tear (Double Rip) Test: A specimen is cut into a tongue-like shape and pulled in two directions to propagate a tear. Standards: ASTM D2261 (for textiles), ISO 13937-2 (for textiles).

- Wing Tear (Graves) Test: The specimen is prepared in a specific rectangular shape with a notch and pulled apart to measure the force to continue the tear. Standards: ASTM D624 (for rubber).

- Wing Tear (Winkelmann) Test: Similar to Graves but with a different geometry and notch orientation. Standards: Specific standards may vary; often used in conjunction with other methods.

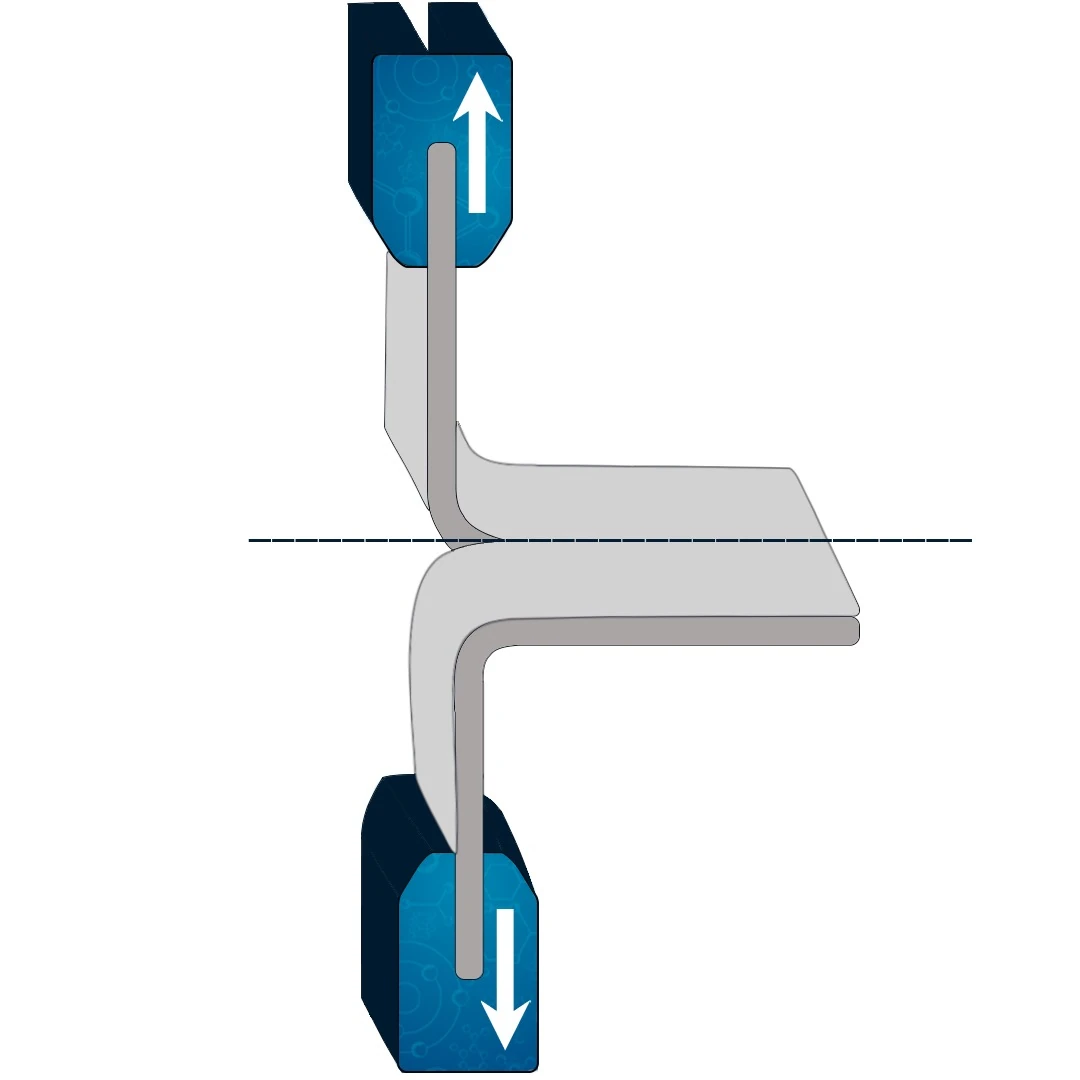

- Trapezoidal Tear Test: Involves cutting the specimen into a trapezoidal shape and pulling it apart from the notched area to propagate the tear. Standards: ASTM D5587 (for textiles), ISO 9073-4 (for textiles).

- Baumann Tear Test: Often used for paper and card materials, where a central cut is made and force is applied to propagate the tear. Standards: TAPPI T414 (for paper).

- Delft Tear Test: Specifically designed for geotextiles, it involves a specific specimen shape and method for evaluating tear resistance. Standards: ISO 9073-4 (for geotextiles).

Different tests may be used based on the specific material, application, and properties being evaluated. The choice of tear test method often depends on factors like material thickness, flexibility, and the nature of the forces the material is expected to encounter in its intended application. Tear testing is essential in applications where resistance to tearing is crucial, such as in industrial textiles, packaging, clothing, and many more.

How to calculate the Tear testing?

Tear testing involves calculating the tear resistance or tear strength of a material based on the force required to initiate or propagate a tear. The calculation may vary depending on the type of tear test being conducted and the specific material being tested. Here’s a general guide to calculating tear testing results:

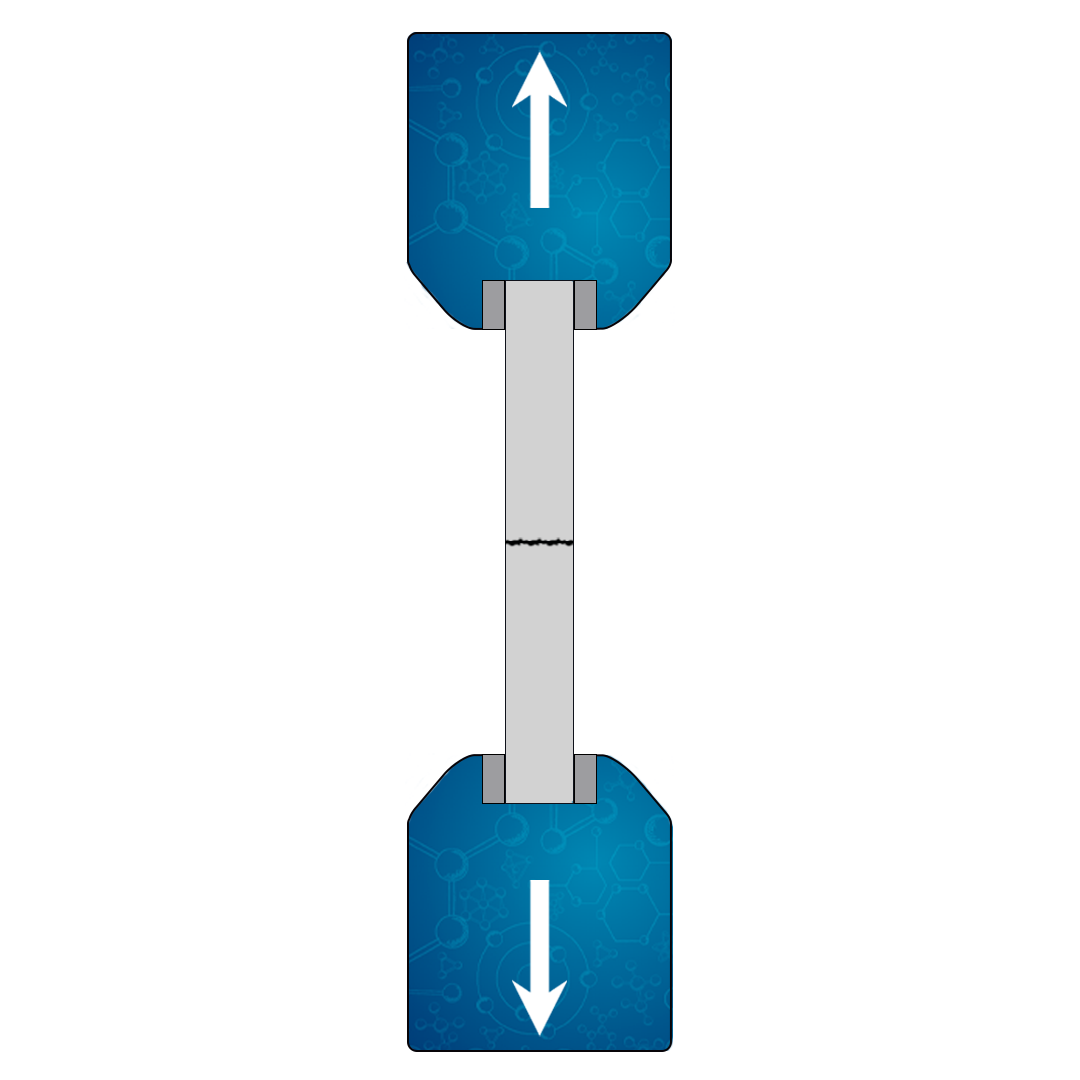

- Sample Preparation: The material must be prepared according to the specific test standard being used. This often involves cutting the material into a specific shape (e.g., trouser, tongue, or wing shape) and making an initial cut or notch to initiate the tear.

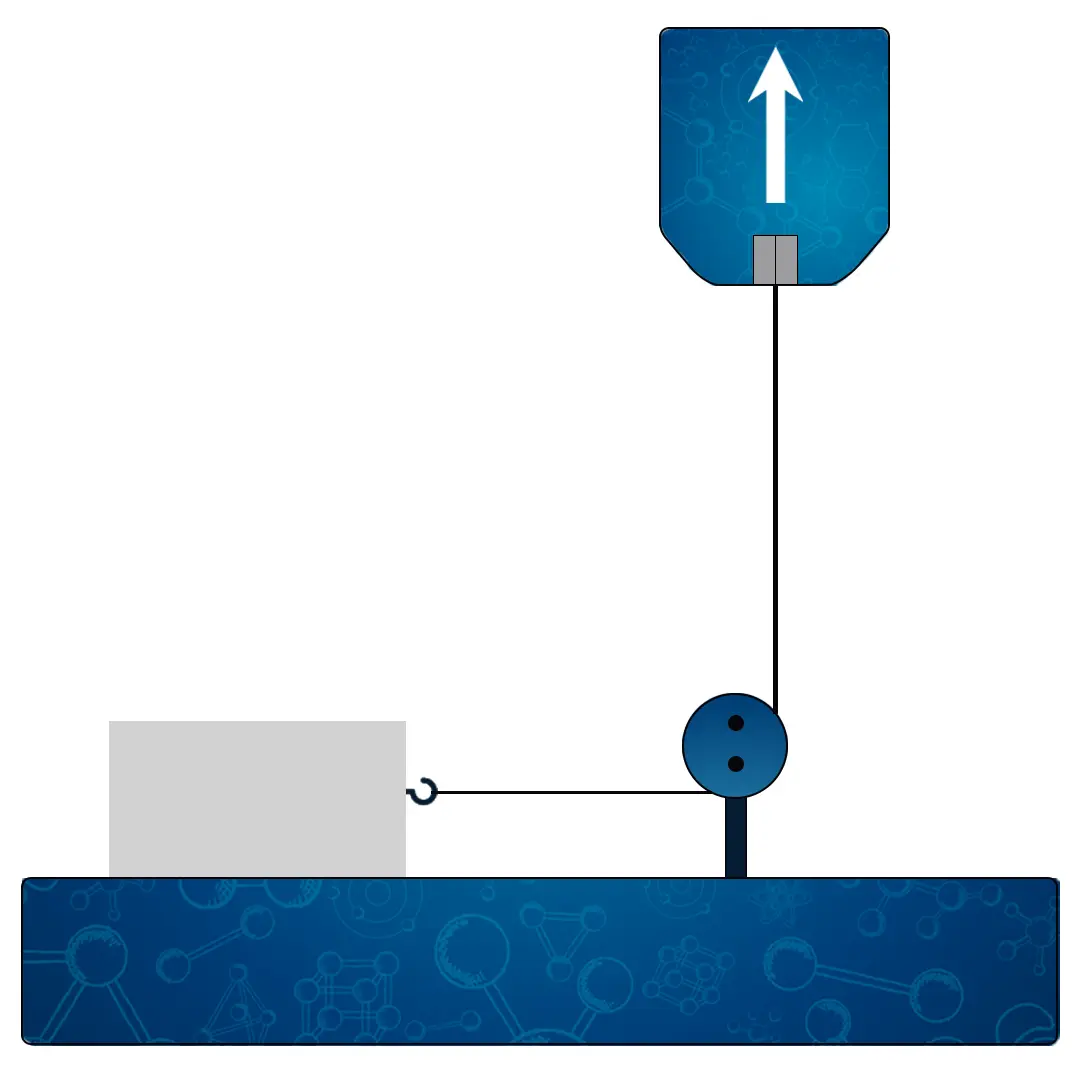

- Test Setup: The sample is mounted into a testing machine designed to apply a tearing force. This could be a tensile testing machine, a pendulum tear tester (as in the Elmendorf method), or another device appropriate to the type of tear test.

- Applying the Force: The machine applies a controlled force to the sample, either by pulling it apart (in tensile tests) or impacting it (in pendulum tests). The force is measured using load cells or other sensors.

- Recording the Force: The force required to initiate or propagate the tear is recorded. In some tests, this may be the peak force reached; in others, it may be the force at a specific point in the tear’s progression.

- Calculating Tear Resistance or Strength: The recorded force is used to calculate the tear resistance or tear strength. This calculation often involves dividing the force by some measure of the material’s thickness, width, or other relevant dimensions. The specific calculation will depend on the test standard and the material being tested.

- Considering Influencing Factors: Various factors can influence tear test results, such as the tear rate, temperature, and humidity. These must be carefully controlled or accounted for in the analysis.

- Report the Results: Results are typically reported in units relevant to the material and application, such as Newtons (N) or pounds-force (lbf) for force, and N/mm or lbf/in for tear strength.

- Example Calculation (Tensile Tear Test): If you’re conducting a tensile tear test and the peak force recorded is 50 N, and the sample thickness is 0.5 mm, the tear strength could be calculated as:

Calculating tear testing results requires careful attention to the specific test method and material characteristics. Adhering to relevant industry standards, such as ASTM or ISO standards, ensures that the results are consistent and comparable across different labs and applications. It’s always advisable to consult the specific standard or test method being used, as it will provide detailed instructions tailored to the material and type of tear test being conducted.

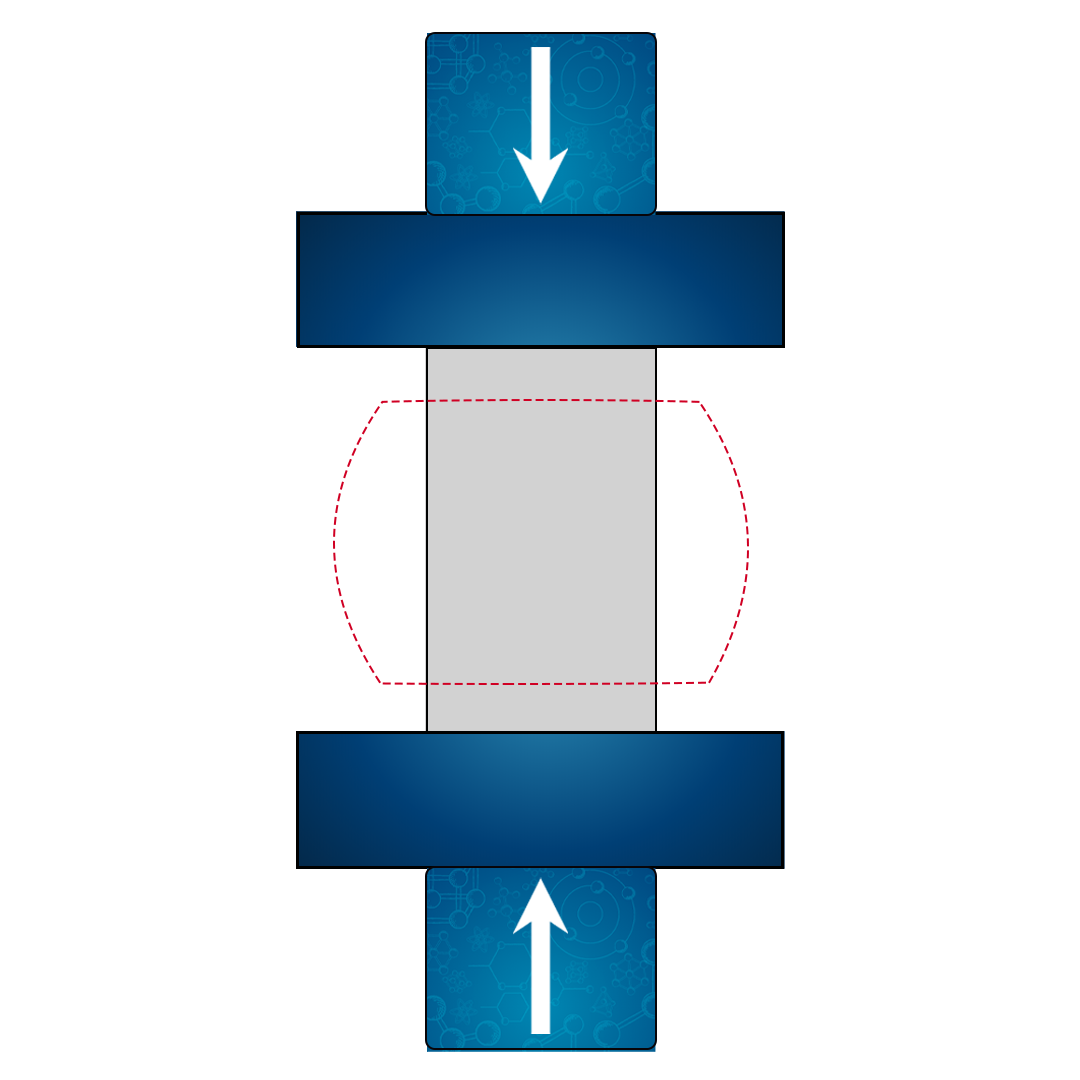

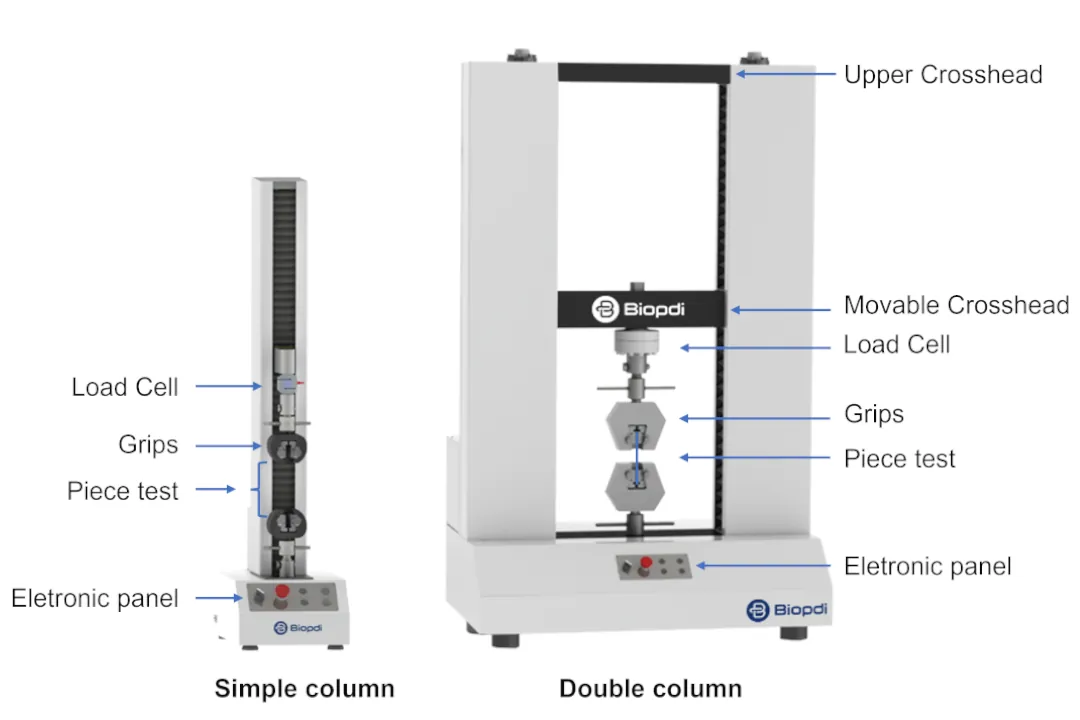

Universal testing machine for tear testing

A Universal Testing Machine (UTM), also known as a universal tester, materials testing machine, or tensile testing machine, is a highly versatile piece of equipment used to conduct various mechanical tests, including tear testing. The UTM is composed of several key parts and components that work in harmony to provide precise and consistent measurements. Here’s a detailed breakdown of the parts and their functions in determining tear testing:

- Load Frame: The load frame is a robust structure that holds the specimen. It can handle substantial loads and maintain the alignment during testing. Its two crossheads move relative to each other; one is typically fixed, and the other is movable.

- Loading System: The loading system applies the force to the specimen. It could be driven by electromechanical, hydraulic, or servo-electric systems, depending upon the model of the UTM and the type of test being conducted.

- Load Cell: The load cell is a transducer that converts force into an electrical signal, which can be measured and recorded. This device helps determine when the material under test has reached its yield point or ultimate strength.

- Grips and Fixtures: These hold the test specimen securely in place during testing. For bend tests, a bend fixture is used, which usually includes a mandrel or plunger and two supporting anvils. The specimen is placed across the supports, and the load is applied at the midpoint by the mandrel.

- Extensometer: This device measures the change in length (or deformation) of the specimen during testing. While not always used in bend tests, it’s important in others, like tension tests.

- Control System: This could be a computer or a dedicated console that controls the UTM’s operation. It manages the movement of the crossheads, the rate of load application, and records the test data.

- Software: Modern UTMs include software to control the machine, collect data, and analyze the results. The software can also generate reports and compare test results against industry standards.

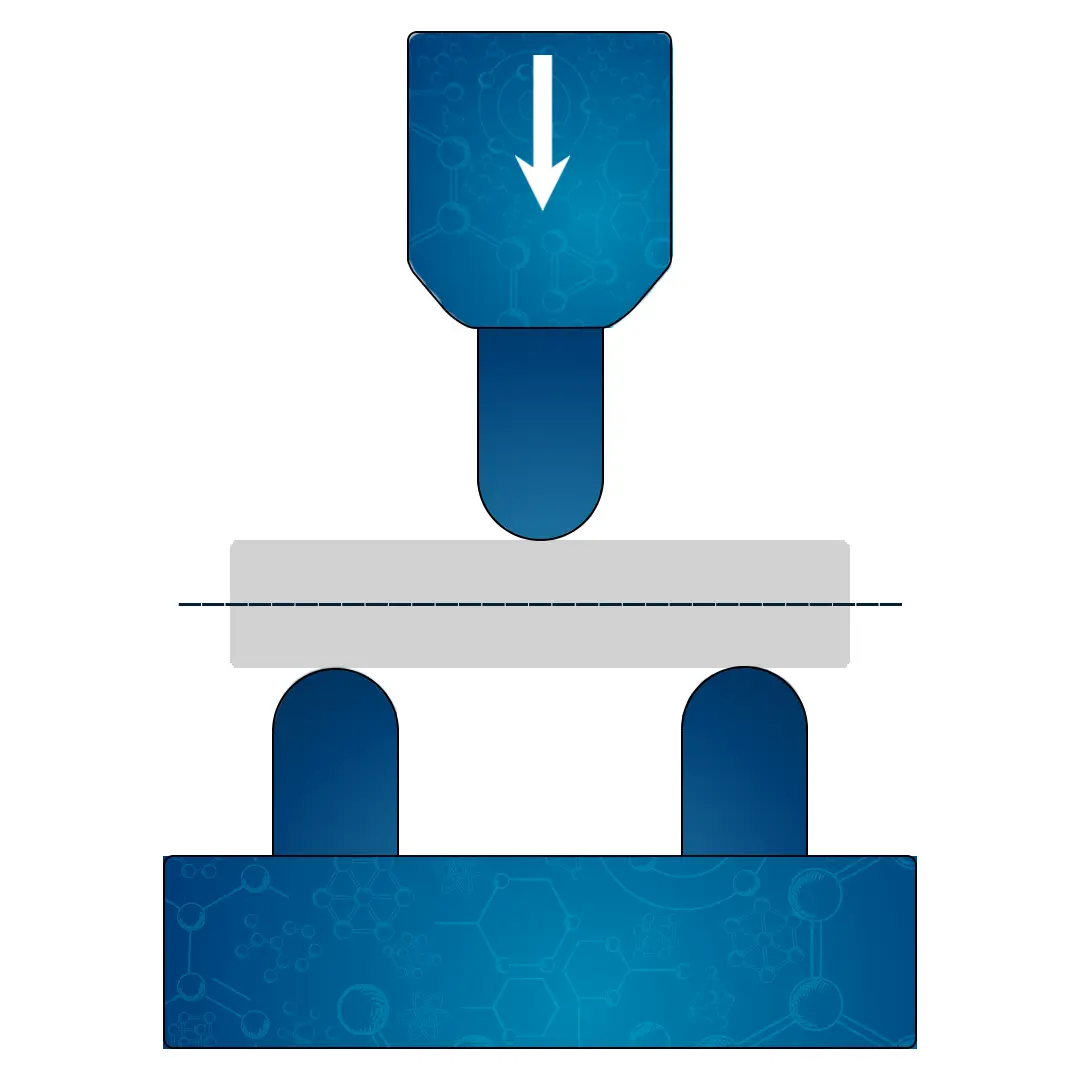

Procedures for conducting a Tear testing using a Universal Testing Machine

Conducting tear testing using a Universal Testing Machine (UTM) is a systematic process that requires careful planning and execution. Here’s a step-by-step guide to the procedures for performing tear testing:

Sample Preparation:

- Choose the Material: Select the material and type of tear test (e.g., trouser tear, wing tear, etc.).

- Cut the Sample: Cut the specimen to the required size and shape, following specific standards relevant to the material and test type.

- Mark the Tear Line: If required, mark the initial tear or notch to ensure consistency across tests.

Configure the Universal Testing Machine:

- Select the Correct Fixtures: Use the appropriate grips or clamps suitable for the material and tear test type.

- Set Up the Load Cell: Choose the load cell with a suitable capacity for the expected forces.

- Configure the Extensometer: If used, set up the extensometer to measure displacement or elongation.

- Set the Environmental Conditions: If required, adjust the temperature and humidity in the environmental chamber.

Calibrate the Machine:

- Perform Calibration: Follow the manufacturer’s instructions to calibrate the machine, ensuring accurate measurements.

- Verify Alignment: Check the alignment of the grips and load cell to prevent uneven loading.

Mount the Sample:

- Secure the Specimen: Place the specimen in the grips or clamps, ensuring it is aligned properly.

- Preload: Apply a small preload to remove slack and ensure consistent contact.

Set Test Parameters:

- Load and Displacement Rates: Define the speed and direction of loading, following relevant standards.

- Test Limits: Set the stopping criteria, such as maximum load, displacement, or specific energy absorbed.

Run the Test:

- Start the Test: Initiate the test using the control panel or software.

- Monitor the Test: Watch the progress and ensure everything is functioning correctly.

- Record Data: The UTM will continuously record force, displacement, and other relevant data.

Analyze and Report:

- Analyze the Results: Use the software to analyze the recorded data, extracting relevant tear properties.

- Create a Report: Compile the results into a report, including material details, test conditions, and observed outcomes.

Post-Test Evaluation:

- Inspect the Sample: Examine the torn sample for any unexpected behavior or failure modes.

- Clean and Store: Clean the machine and store the sample if required for future reference.

Perform Repetitions:

- Repeat the Procedure: Conduct multiple tests if required to ensure statistical validity.

Follow Safety Protocols:

- Ensure Safety: Throughout the procedure, follow all safety guidelines, including proper handling, emergency stops, and protective equipment.

Conducting tear testing using a Universal Testing Machine is a comprehensive procedure that requires meticulous attention to detail. From sample preparation to analysis, each step must be executed with precision and in accordance with relevant standards. Following this systematic approach ensures that the tear testing results are accurate, repeatable, and reflective of the material’s true tear resistance properties. Proper documentation and adherence to safety protocols further enhance the integrity and value of the testing process.

The data obtained in the Tear testing using the Universal Testing Machine

Tear testing using a Universal Testing Machine (UTM) yields valuable information that characterizes the tear resistance and mechanical behavior of materials. Here’s an overview of the types of data and information that can be obtained through tear testing:

Tear Force:

- Definition: The force required to propagate a tear in the material.

- Application: Helps in determining the material’s ability to resist tearing in practical applications.

Tear Energy:

- Definition: The energy absorbed by the material during the tearing process.

- Application: Provides insights into the toughness and energy absorption capacity of the material.

Tear Resistance:

- Definition: A measure of the material’s resistance to the growth of a tear, often calculated as tear force per unit thickness.

- Application: Essential in assessing how well the material can withstand tear propagation under load.

Tear Elongation:

- Definition: The deformation or elongation of the material at the tear point.

- Application: Helps to evaluate the ductility and flexibility of the material.

Tear Initiation Force:

- Definition: The force required to initiate the tear, usually from a predetermined notch.

- Application: Important in understanding the material’s susceptibility to initial tearing or crack propagation.

Tear Propagation Rate:

- Definition: The rate at which a tear advances through the material.

- Application: Provides information on how quickly a tear might spread under specific loading conditions.

Stress-Strain Curve:

- Definition: A plot of stress versus strain that captures the material’s behavior during tearing.

- Application: A comprehensive representation of the material’s mechanical response, including elastic and plastic regions.

Material Thickness:

- Definition: The thickness of the sample, which may influence the tear resistance.

- Application: Essential for normalizing the data and comparing tear resistance across various materials.

Environmental Factors:

- Definition: Conditions like temperature and humidity during the test.

- Application: Crucial for understanding the material’s behavior under different environmental conditions.

Visual Observations:

- Definition: Visual assessment of the tear pattern, failure mode, or any anomalies.

- Application: Adds qualitative insights that complement quantitative data, enhancing understanding of material behavior.

The data obtained from tear testing using a Universal Testing Machine offers an in-depth understanding of a material’s tearing behavior, including its resistance to initiation and propagation of tears, energy absorption characteristics, and response to environmental conditions. These data are vital in materials selection, design, quality control, and failure analysis, providing the foundation for making informed decisions that align with performance requirements and safety standards. The combination of quantitative measurements and qualitative observations ensures a comprehensive evaluation of tear properties, contributing to the broader field of materials science and engineering.

The samples/specimens used to perform the Tear testing in the Universal Testing Machine

Tear testing in a Universal Testing Machine (UTM) requires specimens that are prepared according to specific standards and guidelines. The design of the specimen may vary based on the material, type of tear test, and the standards being followed. Below are the common types of samples or specimens used to perform tear testing:

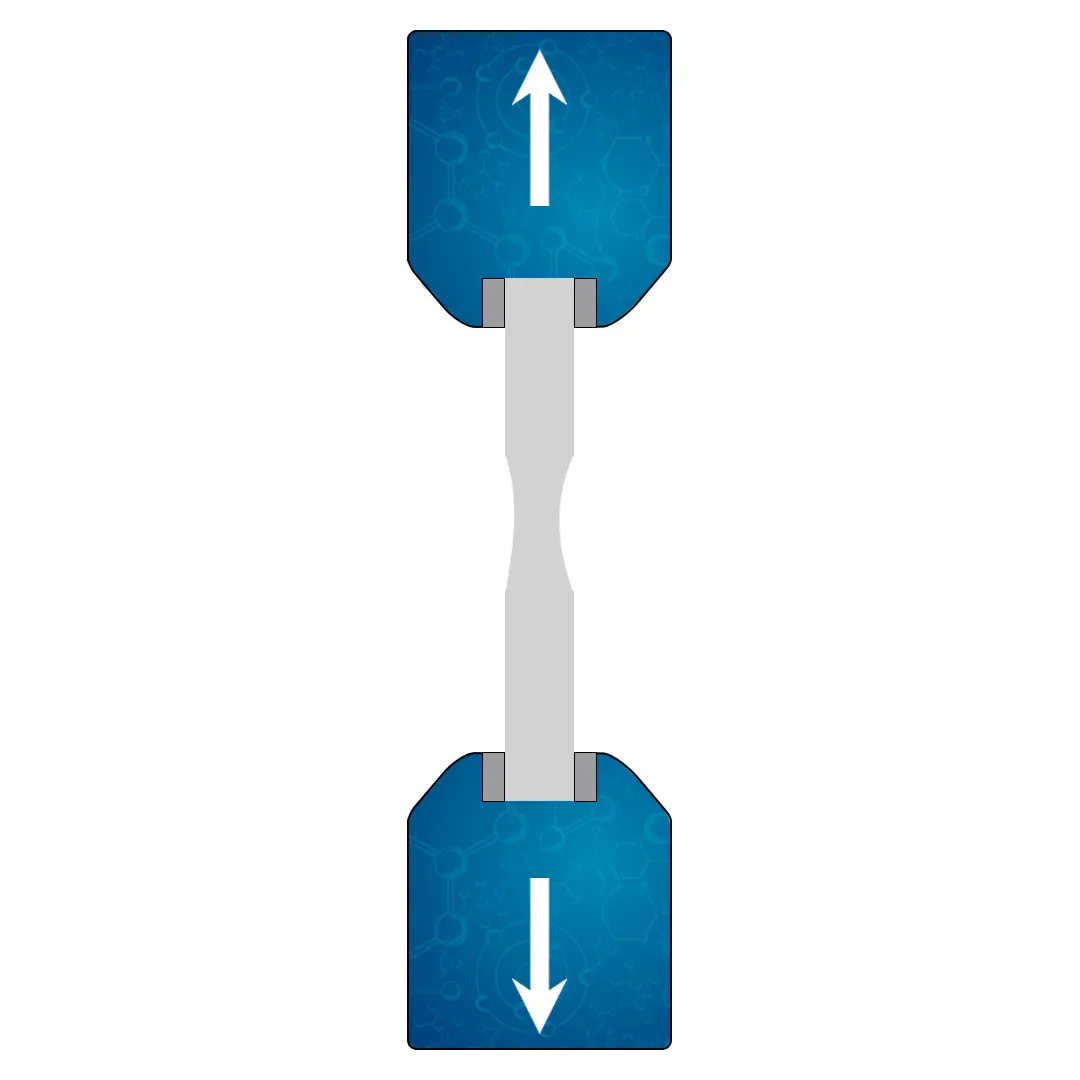

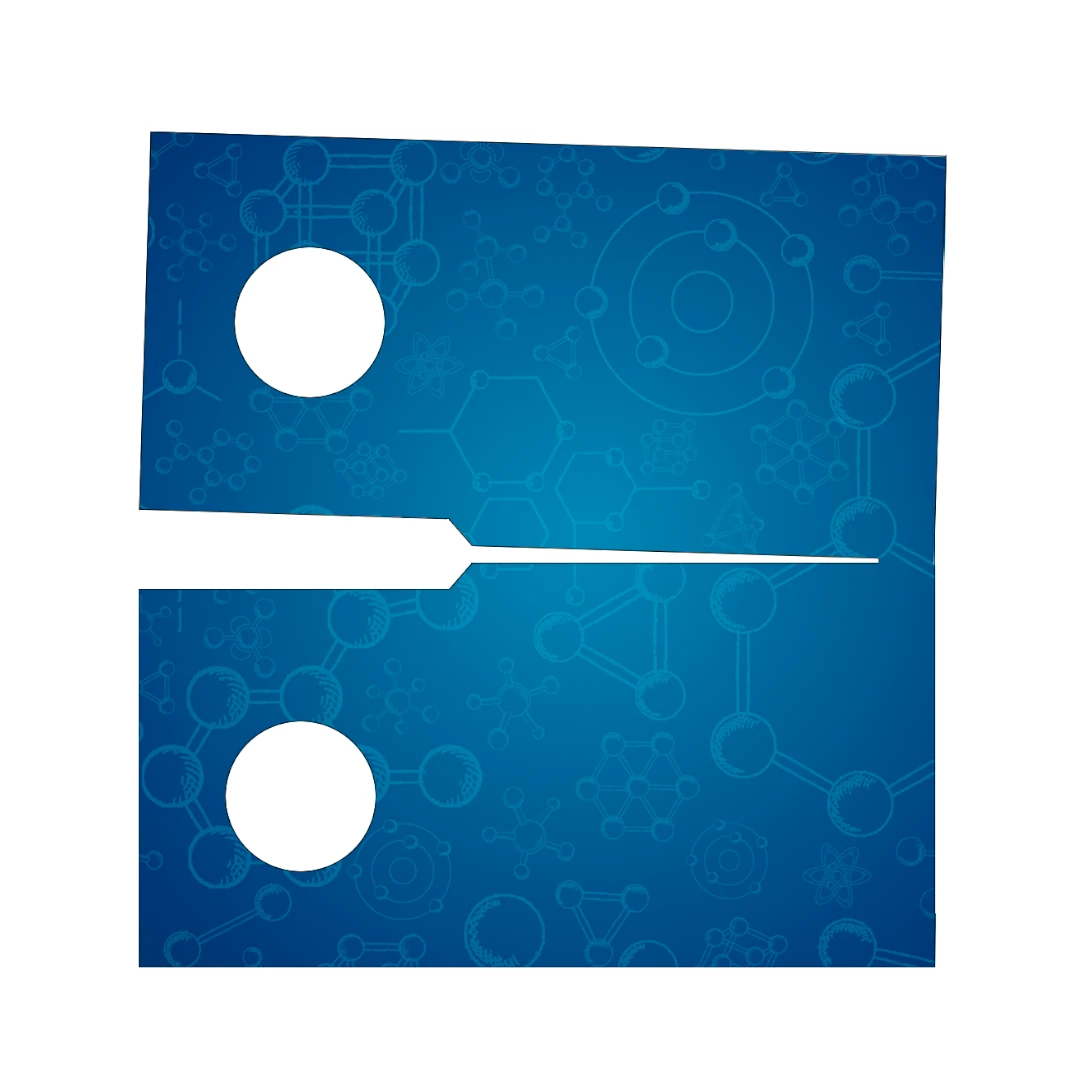

Trouser Tear Specimen:

- Shape: Resembles a pair of trousers, with a central slit dividing the sample into two legs.

- Material: Often used for flexible materials like plastics, rubber, and fabrics.

- Application: Provides information on the force required to propagate a tear from an existing defect.

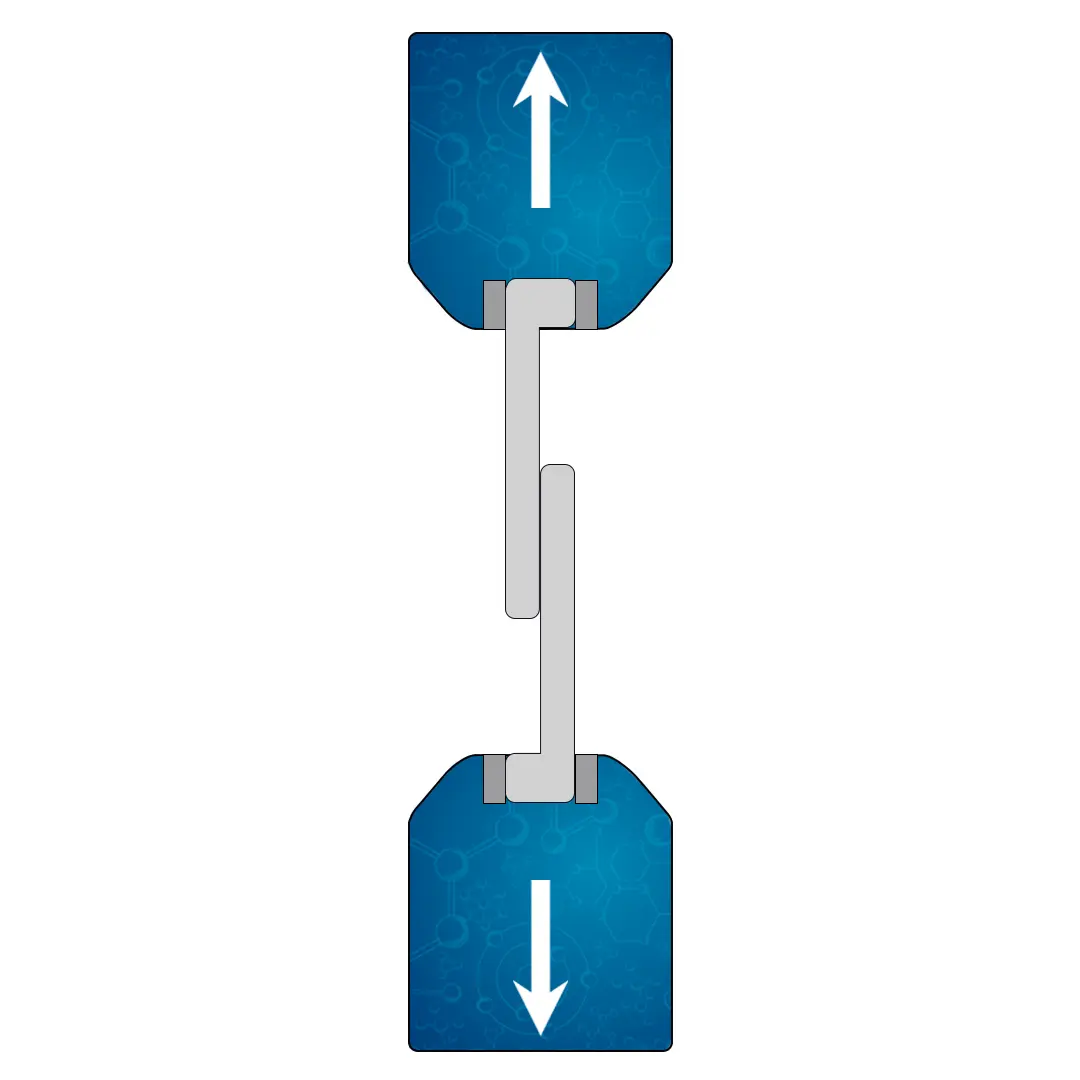

Tongue Tear Specimen:

- Shape: Features two legs and a central tongue or tab created by a slit.

- Material: Suitable for flexible and semi-rigid materials.

- Application: Helps in evaluating both the initiation and propagation of tears.

Wing Tear Specimen (Graves or Winkelmann):

- Shape: Distinctive wing or V-shape with a central notch.

- Material: Commonly used for elastomers, flexible plastics, and films.

- Application: Measures tear resistance under controlled conditions, providing consistent results.

Trapezoidal Tear Specimen:

- Shape: Trapezoidal design with a notch at the shorter parallel side.

- Material: Typically used for textile fabrics and woven materials.

- Application: Useful in assessing tear resistance across different directions of the material.

Baumann Tear Specimen:

- Shape: Rectangular shape with specific dimensions, often with a central notch.

- Material: Utilized for leather and similar materials.

- Application: Provides insights into tear strength and behavior specific to leather goods.

Delft Tear Specimen:

- Shape: Specialized design, often utilized in geotextiles.

- Material: Suitable for geotextiles and related materials.

- Application: Enables the assessment of tear strength in geomembranes and similar materials.

The selection and preparation of the sample or specimen for tear testing in a UTM are critical factors that can significantly influence the results. Various shapes and designs cater to different materials and testing needs, reflecting the diversity and complexity of tear behaviors across different materials. Careful adherence to relevant standards, guidelines, and best practices ensures that the specimen’s dimensions and geometry are appropriate for the material and test type, leading to accurate and reliable tear testing outcomes. Whether testing textiles, plastics, rubber, or specialized materials, the thoughtful design of the specimen is fundamental to the integrity and value of the tear testing process.

Standards for Tear Testing

Tear testing is governed by various international and national standards that outline the specific methods, procedures, and requirements to ensure consistency, accuracy, and comparability of results. Below are ten main standards related to tear testing, with the first five from ISO (International Organization for Standardization) and the last five from ASTM (American Society for Testing and Materials):

ISO Standards

- ISO 34-1:2015: Rubber, vulcanized or thermoplastic – Determination of tear strength – Part 1: Trouser, angle and crescent test pieces. Application: Applied to vulcanized and thermoplastic rubber.

- ISO 9073-4:2019: Textiles — Test methods for nonwovens — Part 4: Determination of tear resistance. Application: Utilized for measuring the tear resistance of nonwoven textiles.

- ISO 6383-2:1983: Plastics – Film and sheeting – Determination of tear resistance – Part 2: Elmendorf method. Application: Used for testing the tear resistance of plastic films and sheeting using the Elmendorf method.

- ISO 13937-2:2000: Textiles – Tear properties of fabrics – Part 2: Determination of tear force of trouser-shaped test specimens. Application: Applied to the determination of tear force in fabrics using trouser-shaped specimens.

- ISO 4674-2:2016: Rubber- or plastics-coated fabrics – Determination of tear resistance – Part 2: Ballistic pendulum method (Elmendorf). Application: Used for rubber- or plastics-coated fabrics, employing the Elmendorf method.

ASTM Standards

- ASTM D1004-13: Standard Test Method for Tear Resistance (Graves Tear) of Plastic Film and Sheeting. Application: Utilized for determining tear resistance in plastic films and sheeting.

- ASTM D1424-09(2013)e1: Standard Test Method for Tearing Strength of Fabrics by Falling-Pendulum (Elmendorf-Type) Apparatus. Application: Applied to fabrics, utilizing the Elmendorf apparatus to determine tearing strength.

- ASTM D1938-19: Standard Test Method for Tear-Propagation Resistance (Trouser Tear) of Plastic Film and Thin Sheeting by a Single-Tear Method. Application:Suitable for measuring tear-propagation resistance in plastic film and thin sheeting.

- ASTM D624-00(2020): Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers. Application: Utilized for determining tear strength in vulcanized rubber and thermoplastic elastomers.

- ASTM D5734-16: Standard Test Method for Shear and Peel Strength of Solvent-Welded Seams with Nonreinforced Geomembranes. Application: Applied to solvent-welded seams with nonreinforced geomembranes, including tests for shear and peel strength.

These standards represent a combination of specific methods and generalized techniques to perform tear testing across a wide range of materials, including rubber, plastics, fabrics, and specialized applications. Adhering to these standards ensures that tear testing is conducted with precision, reliability, and repeatability, promoting international comparability and confidence in the results.

The main applications of the Tear testing

Tear testing plays a vital role in various industries and applications by providing critical insights into the tear resistance and overall durability of materials. Understanding how a material behaves under tear conditions allows designers, engineers, manufacturers, and quality control professionals to make informed decisions. Here are some of the main applications of tear testing:

Product Development and Material Selection:

- Application: Helps in choosing the right materials during the design and development phase.

- Industries: Automotive, aerospace, consumer goods, medical devices, etc.

Quality Control and Assurance:

- Application: Ensures that the materials meet the required standards and specifications.

- Industries: Textiles, plastics, rubber manufacturing, electronics, etc.

Failure Analysis:

- Application: Investigates material failures to identify the causes and prevent future occurrences.

- Industries: Construction, infrastructure, energy, transportation, etc.

Packaging Industry:

- Application: Evaluates the tear resistance of packaging materials to ensure product protection.

- Industries: Food and beverage, pharmaceuticals, electronics, logistics, etc.

Textile and Apparel Industry:

- Application: Assesses the tear strength of fabrics, aiding in garment design and quality control.

- Industries: Clothing, sportswear, upholstery, outdoor equipment, etc.

Rubber and Plastics Industry:

- Application: Determines the tear characteristics of elastomers and polymers for various applications.

- Industries: Tires, seals, gaskets, medical equipment, etc.

Geotextiles and Geomembranes:

- Application: Analyzes tear resistance in civil engineering applications.

- Industries: Road construction, landfills, erosion control, water containment, etc.

Leather Industry:

- Application: Ensures quality and performance in leather products.

- Industries: Footwear, automotive interiors, fashion accessories, etc.

Environmental Impact Studies:

- Application: Evaluates the degradation and wear of materials under different environmental conditions.

- Industries: Environmental protection, weather resistance studies, etc.

Medical Devices and Equipment:

- Application: Validates the integrity and performance of medical materials such as gloves, membranes, and packaging.

- Industries: Medical devices, healthcare, dental, etc.

Tear testing serves a diverse array of applications across various industries. Whether ensuring quality and compliance, driving innovation in product design, or enhancing safety and performance, tear testing provides critical data that guides decision-making. Its universal importance is a testament to the multifaceted nature of materials science and the continued need for robust testing methodologies to meet the evolving demands of modern technology and industry standards.

Additional information about Tear testing

Tear testing is a rich field with many nuances and aspects that may not always be apparent at a glance. Here’s additional information to provide a more comprehensive understanding of this essential testing methodology:

Differentiating Between Tear Strength and Tear Resistance

- Tear Strength: Quantifies the force required to continue tearing a material once it has started.

- Tear Resistance: Refers to the material’s ability to resist the initiation of a tear.

Equipment Considerations

- Various equipment like the Elmendorf tester and trouser tear apparatus can be used, each with unique configurations and applications.

- Calibration and maintenance of the equipment are crucial for accurate measurements.

Environmental Factors

- Temperature, humidity, and other environmental conditions can affect tear properties. Standardized testing often requires controlled environments.

Anisotropic Materials

- Materials with different properties in different directions (anisotropic) may exhibit varied tear behaviors along different axes. Testing may need to be conducted in different orientations.

Relationship with Other Properties

- Tear properties are often related to other mechanical properties like tensile strength, elongation, and hardness. Understanding these relationships can provide deeper insights into material behavior.

Importance in Safety Considerations

- Tear testing can be vital in safety-critical applications like airbags, seat belts, and medical devices, where failure due to tearing could have dire consequences.

Role in Sustainability

- Understanding tear properties can aid in recycling and reusing materials, as well as developing new materials with enhanced durability.

Regulations and Compliance

- Different regions and industries may have specific regulations and standards governing tear testing. Compliance is often legally mandated.

Historical Context

- The methodologies for tear testing have evolved over time, reflecting advances in materials science, technology, and industry needs.

Academic and Research Applications

- Beyond industrial applications, tear testing is also significant in academic and research contexts for developing new materials and understanding fundamental material behaviors.

Tear testing is far from a monolithic or simplistic procedure. Its complexities and intricacies stem from the diverse nature of materials themselves, as well as the multifaceted applications they serve. As materials science continues to advance and new materials are developed, the methodologies, standards, and insights gained from tear testing will continue to evolve. The interplay between theory and practice, innovation and standardization, and the multifarious needs of different industries ensures that tear testing will remain an essential aspect of materials engineering for the foreseeable future. Whether a seasoned professional or someone new to the field, there is always more to learn and explore in the rich domain of tear testing.

Conclusion

The comprehensive analysis of tear testing presented herein has elucidated the vital role that such testing plays in the evaluation of materials, notably within the textile industry. By meticulously investigating the definitions, methodologies, applications, standards, and distinctive characteristics of these test, insights have been furnished into the manner in which this augment material selection, quality control, and product development.

Whether in the context of assessing the propagation of tears or deciphering the stretching capacities of fabrics, these examinations function as essential instruments for engineers and designers.

The information conveyed herein accentuates the intricacy and significance of these assessments, reconfirming their indispensable contribution to ensuring the performance, durability, and appropriateness of materials for various applications.

FAQs

What is tear testing?

Tear testing measures the force required to continue a tear in a material once it has been initiated, assessing the material’s resistance to tearing.

What are the methods of tear testing?

Common methods include Trouser tear, Tongue tear, Wing tear (Graves), Wing tear (Winkelmann), Trapezoidal tear, Baumann tear, and Delft tear.

What is the tear test for materials?

Tear tests for materials evaluate how a material behaves when a tear is initiated, giving insights into its ability to withstand and resist tearing forces.

How to do a tear strength test?

A tear strength test involves cutting a specimen in a specific shape, clamping it in a testing machine, applying a force to initiate and propagate the tear, and recording the force required.

How long does a tear test take?

The duration of a tear test depends on the material, machine settings, and standard followed, but it typically takes a few minutes.

Why is tear testing important?

Tear testing helps assess a material’s ability to resist tearing, vital for quality control, material selection, and ensuring durability in various applications.

What is the difference between tear test and tensile test?

Tear testing measures resistance to the propagation of a tear, while tensile testing assesses the material’s resistance to uniform stretching.

What is a tear strength tester?

A tear strength tester is a specialized machine used to perform tear testing, quantifying a material’s ability to resist tearing.

What is rubber tear test?

Rubber tear test evaluates the tear resistance of rubber materials, crucial for applications where elasticity and resistance to tearing are essential.

What is a normal tear amount?

A “normal” tear amount varies by material, application, and standard used; it’s the value that is acceptable or expected for a given context.

What is the ISO standard for tear test?

For rubber, the ISO standard is ISO 34. Standards may vary depending on material and test method.

What materials are tear resistant?

Materials like high-denier nylon, Kevlar, and certain polymeric substances are known for their tear resistance.

What is the ASTM standard for tear strength of fabric?

ASTM D2261 and ASTM D624 are commonly used for fabric tear strength testing.

What is the difference between tear strength and tear resistance?

Tear strength quantifies the force needed to propagate a tear, while tear resistance refers to a material’s ability to prevent the initiation of a tear.

What is the difference between tear strength and stiffness?

Tear strength relates to resistance to tearing, while stiffness refers to a material’s resistance to deformation under an applied force.

What is tear strength of plastic?

Tear strength of plastic refers to the force required to propagate a tear in a plastic material, with values depending on the type and formulation of the plastic.

See more relevant posts

TENSILE TEST

Tensile testing is a crucial mechanical test used to evaluate the strength and ductility of materials. It involves applying a controlled force. See more

COMPRESSION TEST

Compression testing is a fundamental evaluation method employed to assess a material's ability to withstand compressive forces. See more

SHEAR TEST

Shear testing examines a material's response to forces acting parallel to its surface. By applying a force that causes one part of the material. See more

BEND TEST

Bend testing is a mechanical test that determines a material's flexibility and resistance to fracture under bending forces. See more

FLEXURAL TEST

Flexural testing, also known as the three-point bend test, is employed to measure a material's resistance to bending or flexural stress. See more

FRICTION TEST

Coefficient of friction test measures the amount of resistance between two surfaces in contact when one moves relative to the other. See more

TEAR TEST

Tear test determines a material's resistance to tearing forces, often encountered in applications involving thin films, fabrics. See more

PEEL TEST

Peel testing evaluates the strength of adhesion between two materials, typically an adhesive and a substrate. The test involves separating. See more

BOND TEST

Bond test measures the strength of a bond between two materials. It's used in adhesive and weld test. It helps in determining the reliability of joints and interfaces. See more

INDENTATION TEST

Indentation Force Deflection (IFD) is used to characterize the cushioning or compressive properties of a material, especially foams and soft polymers. See more

FRACTURE TEST

Fracture toughness is a material's ability to resist crack propagation. This property is vital for assessing a material's suitability for applications where structural. See more

PUNCTURE TEST

Puncture test examines a material's ability to withstand penetration by sharp objects or forces. This test to evaluate puncture strength and design materials. See more

CRUSH TEST

Crush resistance test measures a material's ability to resist deformation, particularly in terms of compressive force. See more

TORSION TEST

Torsion testing is a critical method in materials engineering, examining how products and materials behave under twisting forces. See more

AXIAL TORSION TEST

Axial torsion test examines a material's behavior when subjected to simultaneous axial and torsional loads. This test to study shear stress. See more

FATIGUE TEST

Fatigue Testing is the evaluation of a material's endurance and failure under repeated stress and cyclic loading conditions. See more.

Author: Mardoqueu M. Costa (Entrepreneur, researcher and writer). I have been working for several years in materials science and engineering and biomedical engineering with emphasis on Entrepreneurship. My focus is on the development of equipment, software, mechanical tests, and the evaluation and creation of new businesses. As a researcher and writer, I have contributed to scientific publications and patents, also working as a technical-scientific consultant for several companies. This integrated approach reflects my commitment to innovation and impact in the technology industry.

Contact us

Phones:

+1 (781) 328 - 2010

sales@biopdi.com

Address:

2 Burlington Woods Dr, Burlington, Massachusetts, United States