Bond Test: The Ultimate Guide to Material Adhesion Testing

The bond test is an important test in materials science that provides information about the cohesive and adhesive properties of various materials. In the following sections, we will explore in depth its importance, types, advantages, applications, and more. This comprehensive study will provide readers with everything necessary to understand this important testing method.

What is the bond Test?

Bond testing is a specific procedure in materials science and engineering that evaluates the integrity, strength, and quality of the bond or adhesion between two materials or interfaces. This type of testing ensures that the bond, whether it is an adhesive bond, a mechanical bond, or some other form, is reliable and will function as intended under a variety of conditions.

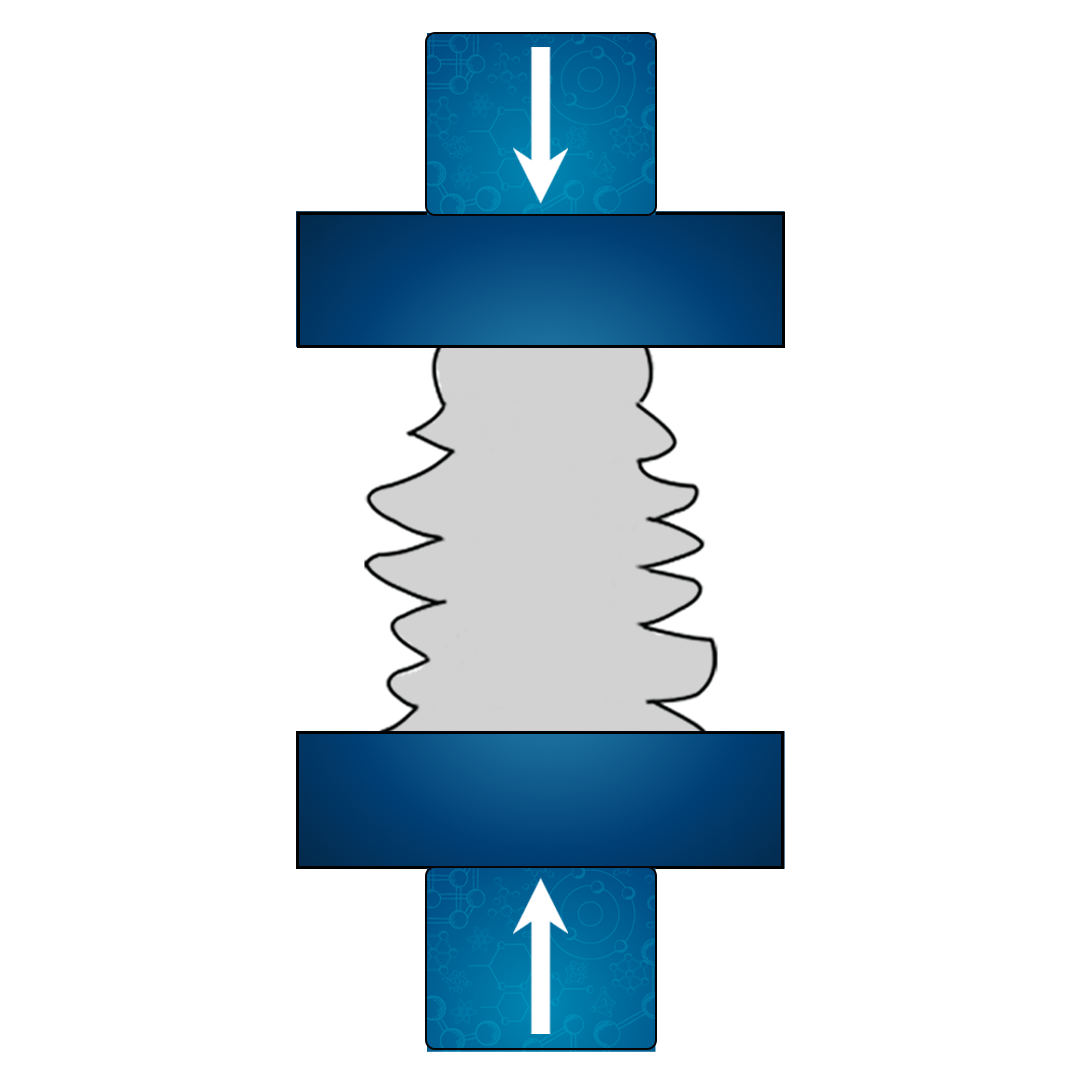

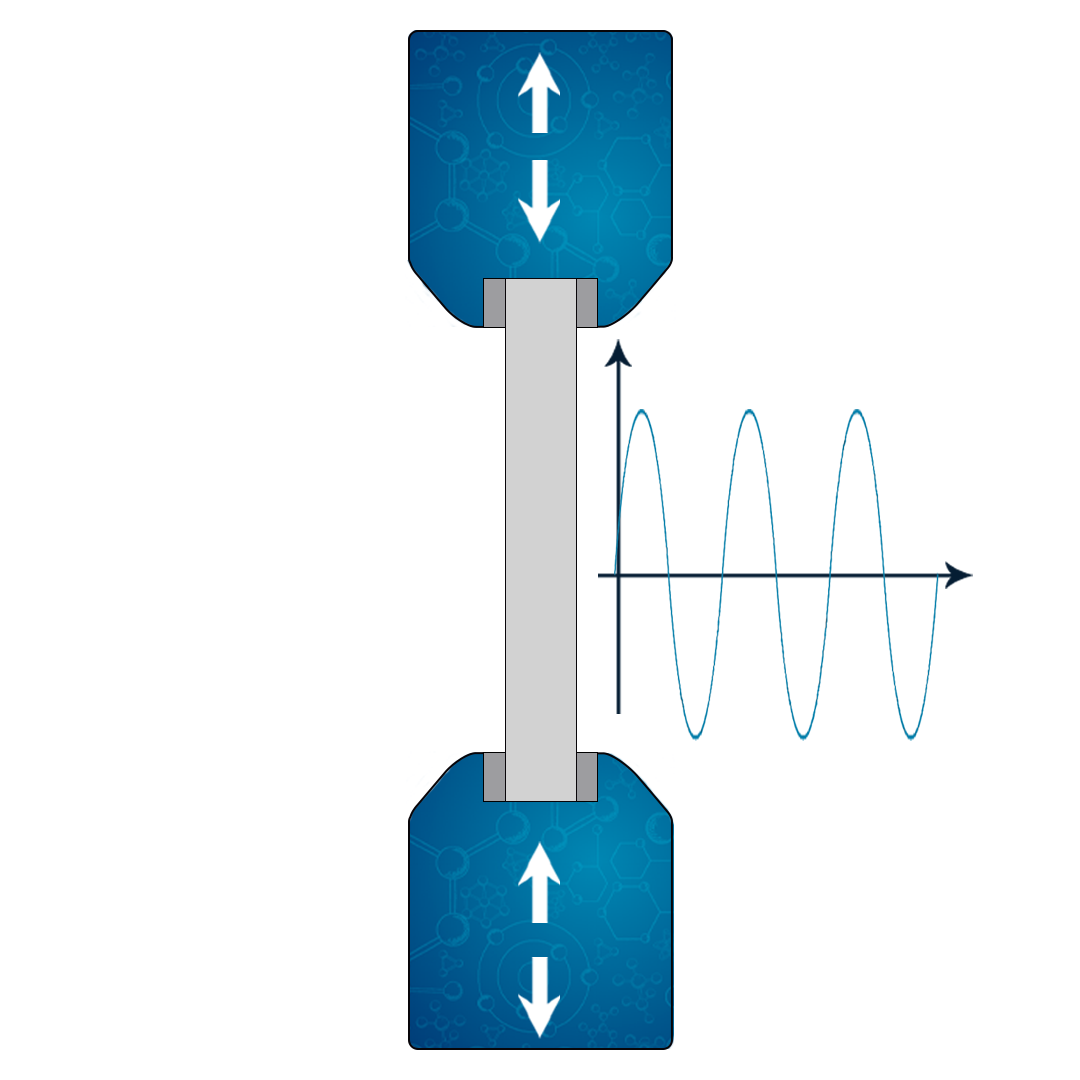

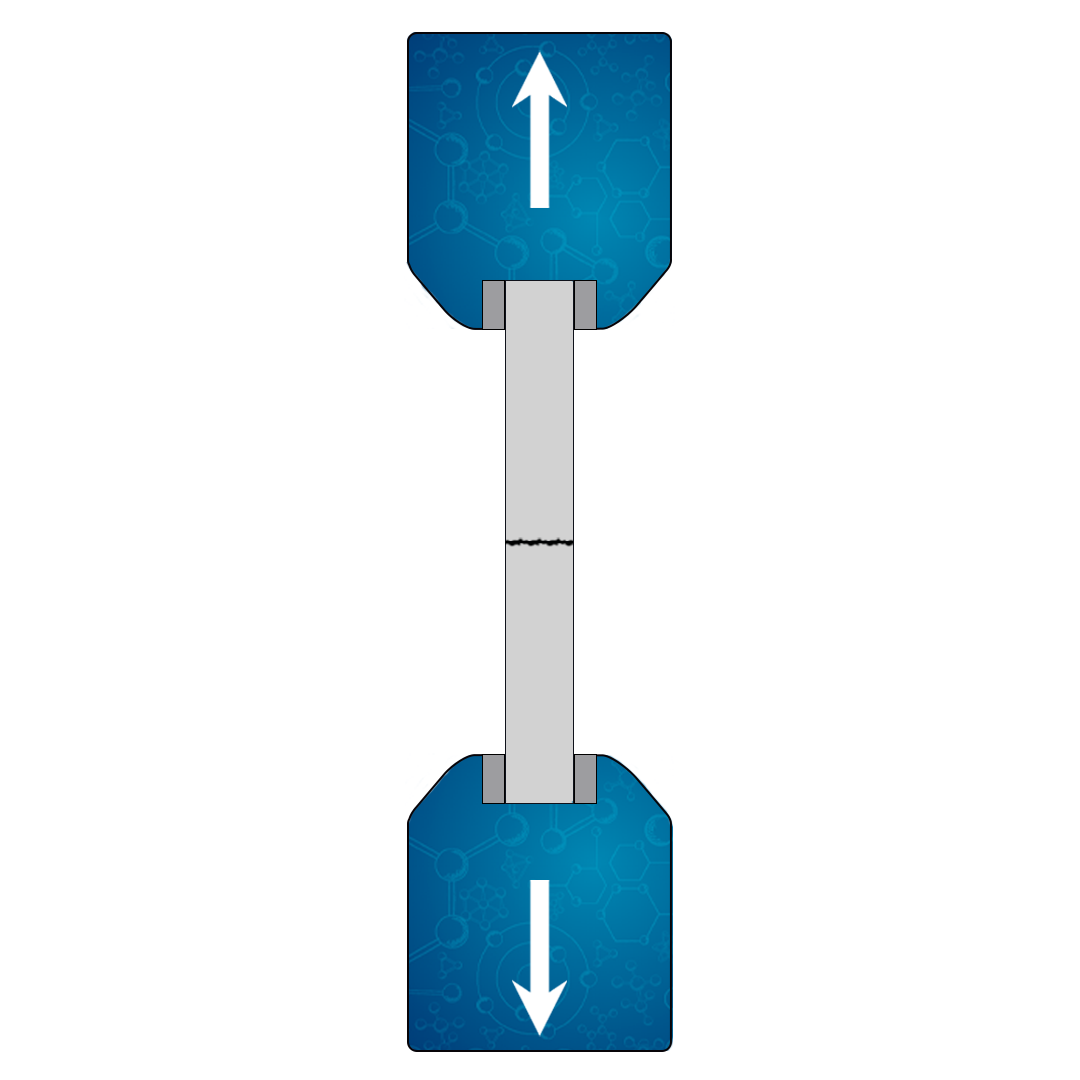

In this procedure, various mechanical and non-destructive tests are performed to assess how bonded materials react to forces such as tension, compression, shear or bending. The aim is to identify possible weak points or defects in the bonding that could lead to reduced performance or safety of the end product.

Bond test is widely used across many industries, including construction, aerospace, automotive, and electronics, to guarantee the efficiency of different products and materials that rely on strong bonds for their functionality.

The properties obtained in the Bond test

The Bond test, utilized in various industries and applications, provides a comprehensive analysis of the characteristics and properties of the bonded materials. Here’s an overview of the critical properties that can be obtained through bond testing:

- Bond Strength: This measures the force required to break the bond between the materials. It is often expressed in terms like tensile strength, shear strength, and peel strength, depending on the type of load applied during testing.

- Mode of Failure: By examining how and where a bond breaks, it’s possible to understand if the failure occurred within the adhesive, at the interface, or in one of the bonded materials. This analysis can guide material selection, design changes, or manufacturing process improvements.

- Adhesion Quality: Adhesion quality refers to how well the materials stick together at the interface. It provides insight into the effectiveness of the adhesive or the bonding process used.

- Deformation and Elasticity: This aspect analyzes how the bond behaves under stress, including its ability to return to its original shape after being deformed. It helps in understanding the flexibility and rigidity of the bond.

- Durability and Fatigue Resistance: By subjecting the bond to repeated stresses or environmental conditions over time, it’s possible to assess how it will perform over the product’s life. This test can highlight issues related to wear, aging, and fatigue.

- Environmental Resistance: This assesses how the bond performs under various environmental conditions, such as temperature, humidity, or exposure to specific chemicals. It’s essential for products that will be used in demanding or outdoor environments.

- Compliance with Standards: Many industries have specific regulations or standards that bonded products must meet. Bond testing verifies that the materials and the bonding process comply with these requirements.

- Surface Preparation and Treatment Effectiveness: In many bonding applications, surfaces must be treated or prepared to ensure a strong bond. The bond test can help determine the effectiveness of these treatments.

- Energy Absorption: This property indicates how much energy the bond can absorb before failure. It is a crucial factor in applications where the bond must dissipate energy, such as in automotive safety components.

- Thermal Properties: This includes understanding how the bond reacts to temperature changes, including expansion, contraction, and potential degradation at extreme temperatures.

bond testing offers a multifaceted view of the connection between materials, encompassing strength, durability, elasticity, failure modes, and various environmental factors. By analyzing these properties, engineers and scientists can make informed decisions on material selection, design, and manufacturing processes, ensuring the integrity, performance, and safety of the bonded structures.

Universal testing machine for bond test

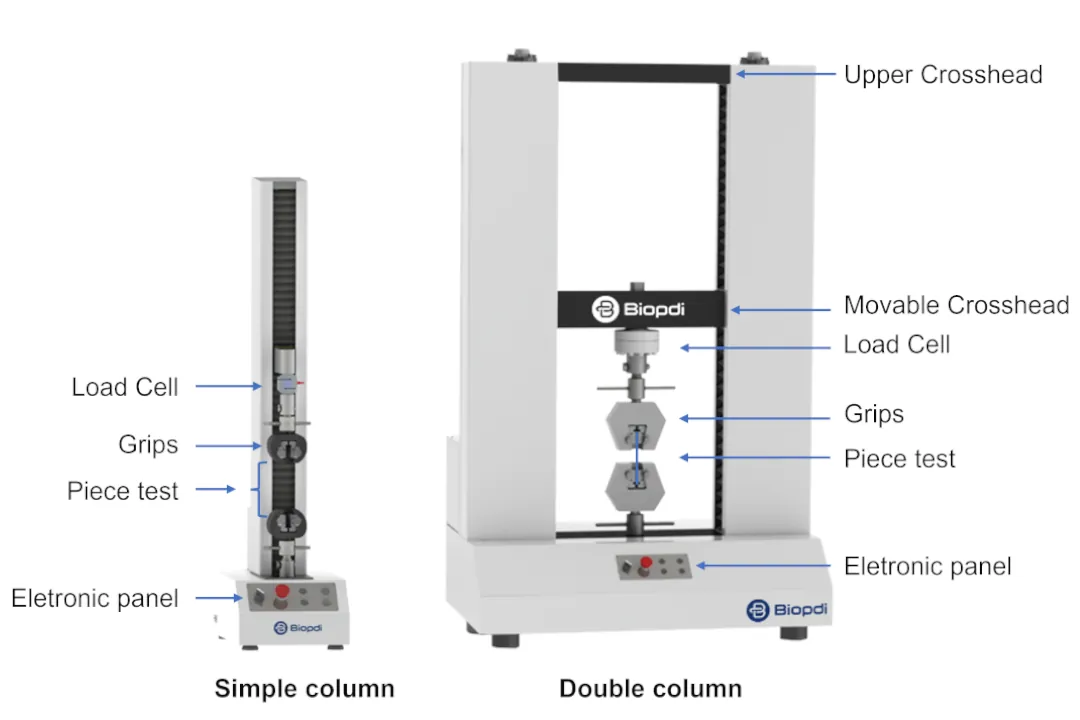

A Universal Testing Machine (UTM), also known as a universal tester, materials testing machine, or tensile testing machine, is a crucial piece of equipment in the field of material science and engineering. It’s versatile enough to perform various types of mechanical tests, including Bond test.

Below are the essential parts and components of a UTM used in bond testing:

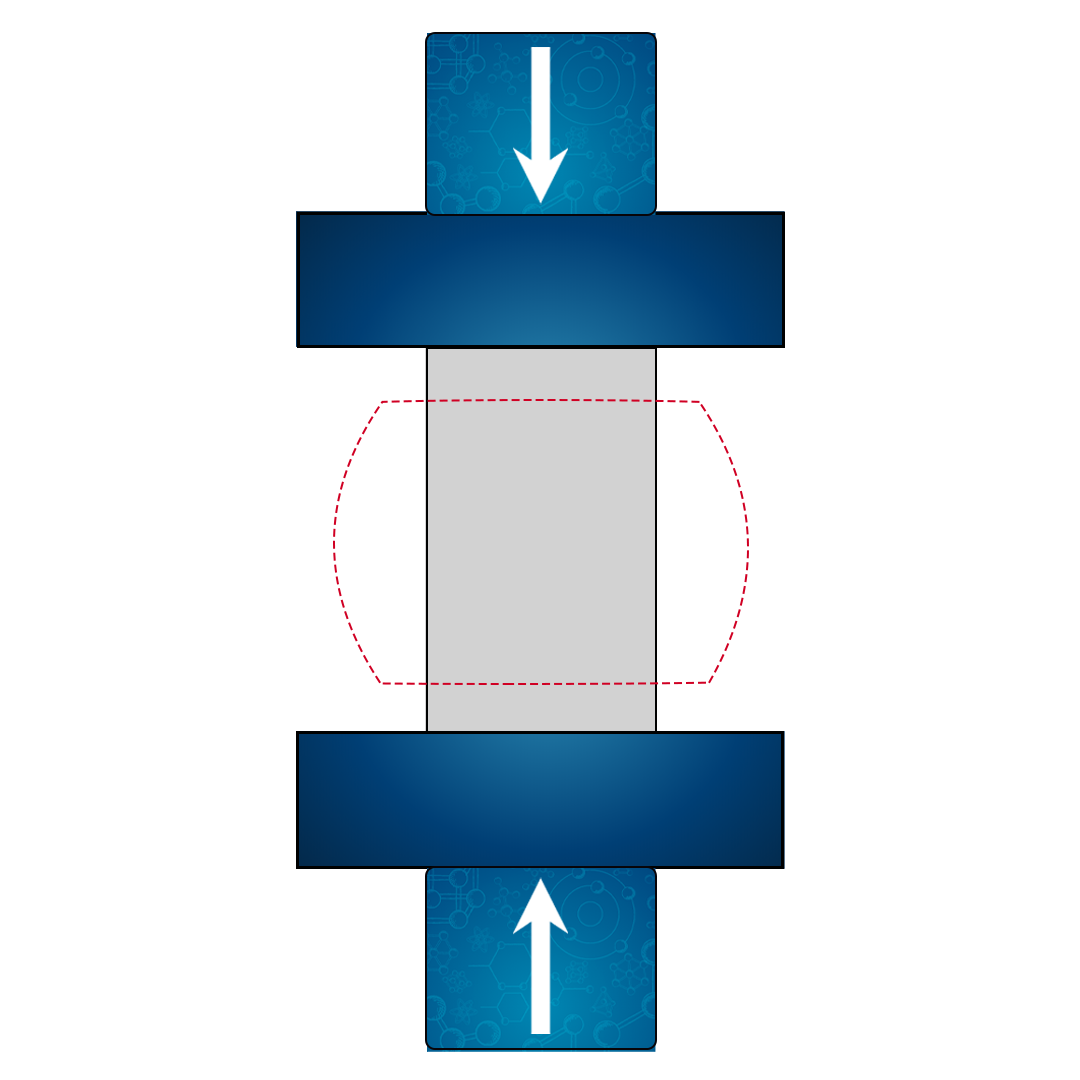

- Load Frame: The load frame is the primary structure of the UTM, typically composed of two strong vertical columns connected by a top and bottom crosshead. This rigid structure is designed to accommodate the high stress generated during testing.

- Crossheads: These are positioned at the top and bottom of the load frame. The upper crosshead is usually stationary, while the lower crosshead can be adjusted depending on the length of the specimen.

- Load Cell: This is a transducer that converts force into an electrical signal, allowing the UTM to measure the load applied to the specimen. Its accurate calibration is crucial for precise testing.

- Actuator: Typically driven by hydraulic, mechanical, or electromechanical means, the actuator applies the required load on the specimen. In some machines, the actuator’s position is adjustable to accommodate specimens of different sizes.

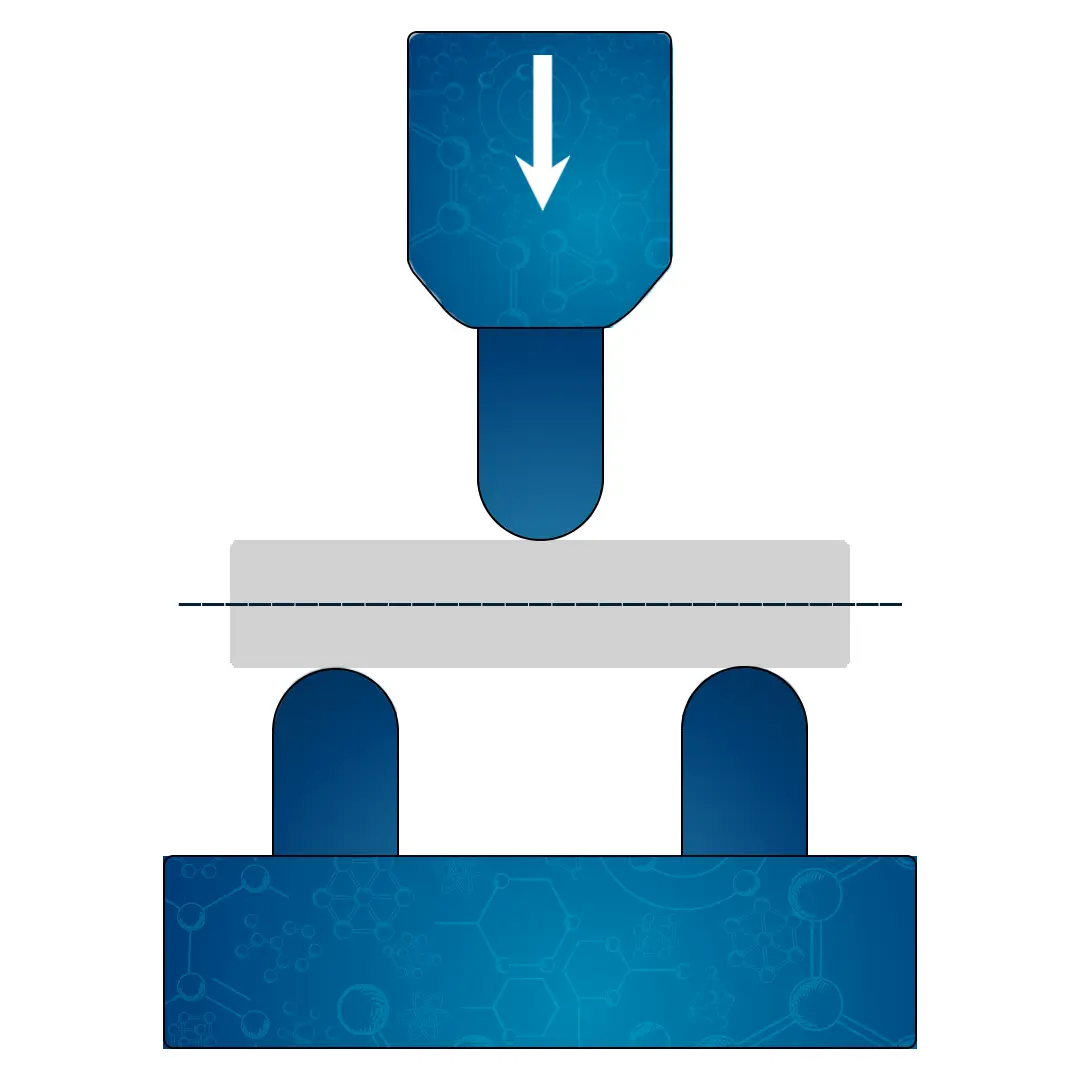

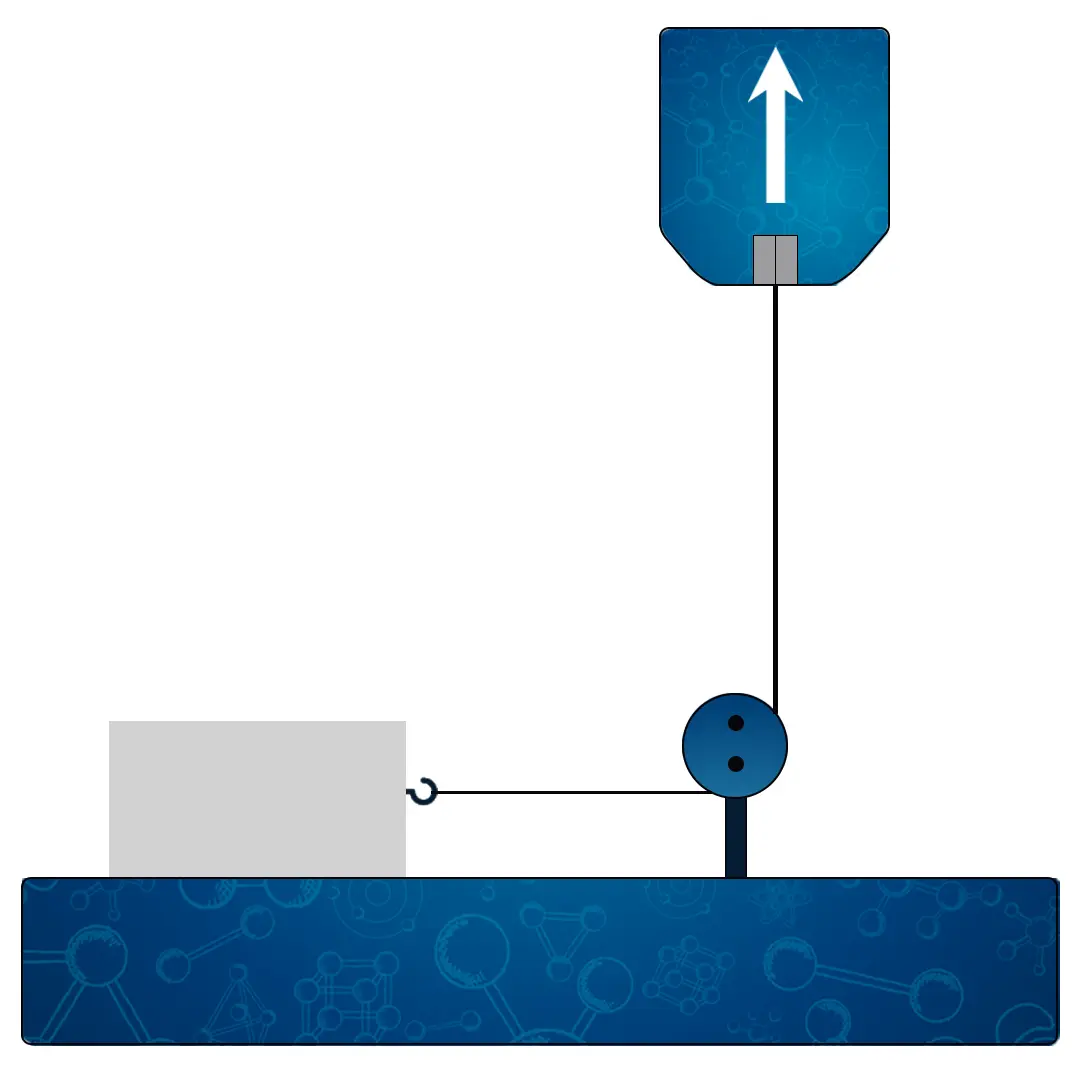

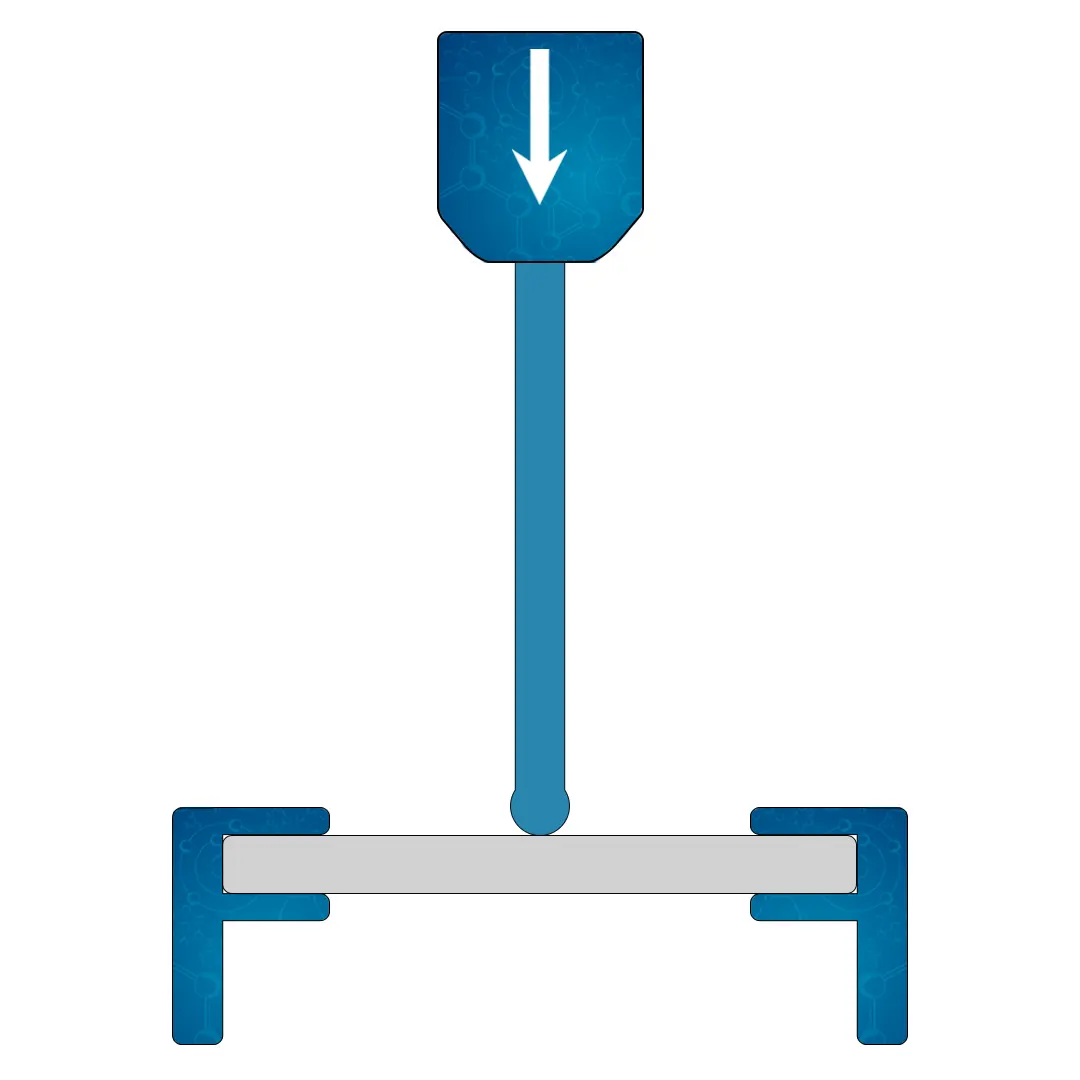

- Grips/ Fixtures: These hold the test specimen in place during testing. For bond test, a specific bond test fixture might be used. The grips/fixtures must be chosen carefully to ensure they don’t slip or induce additional stresses that could interfere with the test results.

- Control Unit: This component controls the speed and direction of the load, the parameters of the test, and other variables. In modern UTMs, the control unit is typically a computer running specialized software.

- Output Device: This could be a computer monitor or a printer that provides a visual representation of the test results, often in the form of a stress-strain graph or a detailed test report.

- Safety Guards: These are essential to protect operators from flying debris in case of a specimen fracture or fixture failure.

Each of these components plays a critical role in the functioning of a UTM. For accurate and reliable results, the UTM should be regularly calibrated and maintained according to the manufacturer’s guidelines and relevant industry standards.

Universal Testing Machine used in the bond test

Procedures for Conducting Bond Test using Universal Testing Machine

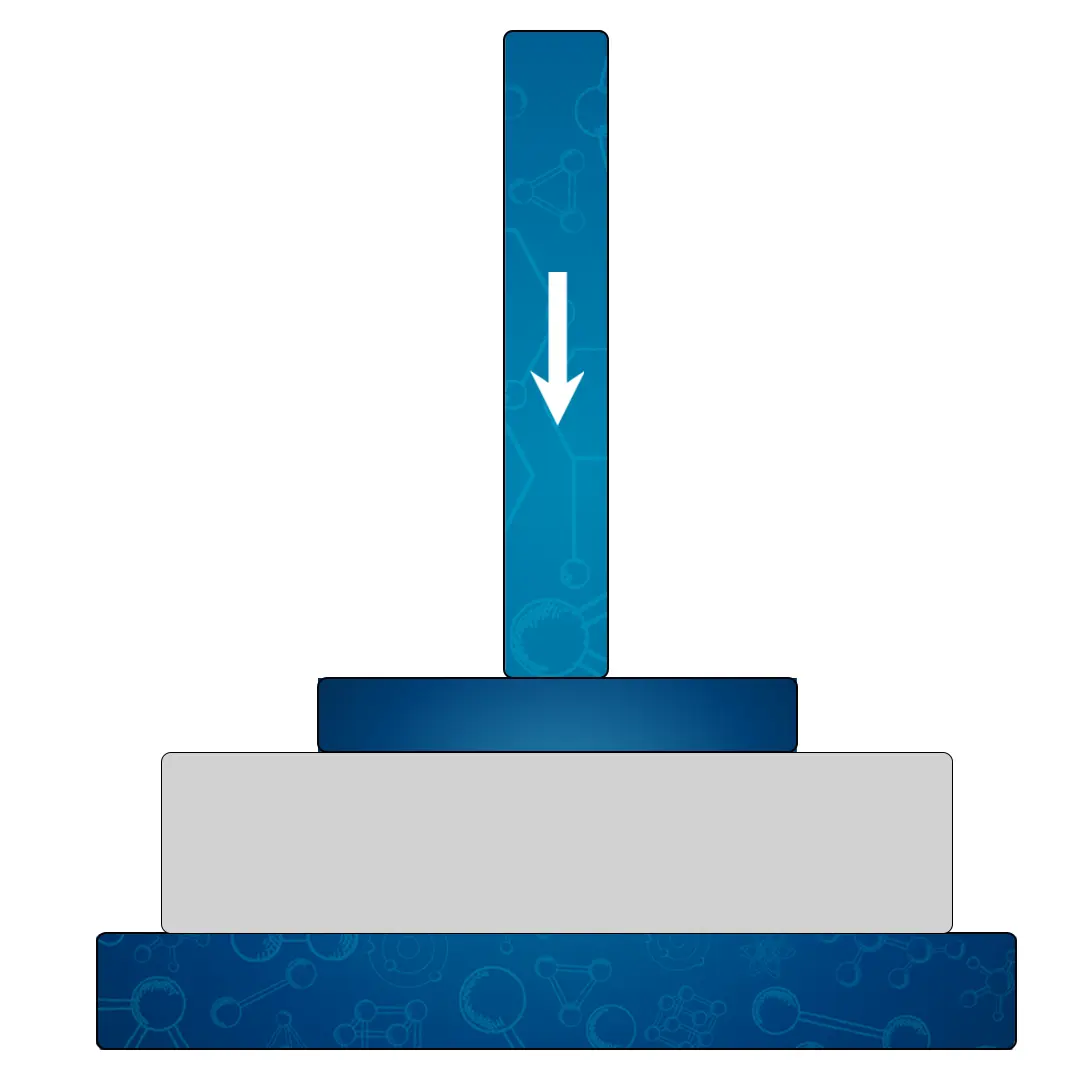

Conducting a Bond test using a UTM involves a detailed procedure:

- Preparation of Samples: Properly prepared according to specifications.

- Placement in the Testing Machine: The specimen must be accurately placed and aligned.

- Load Application: Gradual load is applied according to the standard being followed.

- Monitoring and Data Recording: Continuous monitoring of the test to record essential data.

- Analysis and Interpretation: The data is analyzed to determine the bond properties.

Data Obtained in Bond Test using Universal Testing Machine

The data collected from the UTM during a Bond test is pivotal in understanding the material’s properties:

- Load vs. Displacement Curve: Provides insights into material stiffness and strength.

- Maximum Load: The peak load the specimen can withstand.

- Bond Strength: Calculated from the maximum load and the area being tested.

- Failure Mode: Understanding how the material failed gives clues to its limitations.

Samples/Specimens Used

The samples or specimens must be carefully prepared and selected, with consideration for geometry, thickness, and surface finish. Examples include cylindrical specimens for pull-off tests, bonded plates for shear tests, and others depending on the specific test method.

Main Standards for Obtaining the Bond Test

Adhering to international standards is vital for the credibility and reliability of the Bond test results:

ISO Standards:

- ISO 4624: Pull-off test for paints and coatings.

- ISO 16276-1: Assessment of pull-off resistance.

- ISO 13007-2: Adhesives in tiles and building construction.

- ISO 4587: Adhesives – Determination of tensile lap-shear strength.

- ISO 13702: Oil and gas industry – Control and mitigation of fires and explosions.

ASTM Standards:

- ASTM A944-10: Standard Test Method for Comparing Bond Strength of Steel Reinforcing Bars to Concrete Using Beam-End Specimens.

- ASTM D952: Standard Test Method for Bond or Cohesive Strength of Sheet Plastics and Electrical Insulating Materials

- ASTM D3762: Standard Test Method for Adhesive-Bonded Surface Durability of Aluminum (Wedge Test) (Withdrawn 2019).

- ASTM C1583: Tensile strength of concrete surfaces.

- ASTM D3167: Floating roller peel resistance of adhesives.

Main Applications of the Bond Test

The Bond test finds widespread applications across various industries:

- Construction Industry: Ensuring the integrity of materials like concrete, coatings, and adhesives.

- Aerospace and Automotive Sectors: In the production and quality assessment of critical components.

- Electronics Manufacturing: In the bonding of layers and components.

- Medical Devices: Ensuring the reliability and performance of medical equipment.

- Quality Control in Various Industries: For consistent product quality and compliance with regulations.

Additional Information about Bond Test

The Bond test is not just a simple measurement but a comprehensive assessment. Specialized equipment and trained technicians are often required to conduct these tests. The understanding of failure modes and the comprehensive analysis of data further make the Bond test a nuanced process, integral to modern material science.

Conclusion

Through our exploration of the Bond test, we’ve uncovered its fundamental role in materials science, its wide-ranging applications, the intricacies of conducting the test, and its standards. The Bond test is an invaluable tool for understanding and predicting material behavior, thereby ensuring safety, performance, and innovation across various domains.

FAQs

What is meant by bonding test?

A bonding test refers to the evaluation of the adhesion or bonding strength between materials. It’s essential for determining how materials interact with one another in various applications.

How is bonding test done?

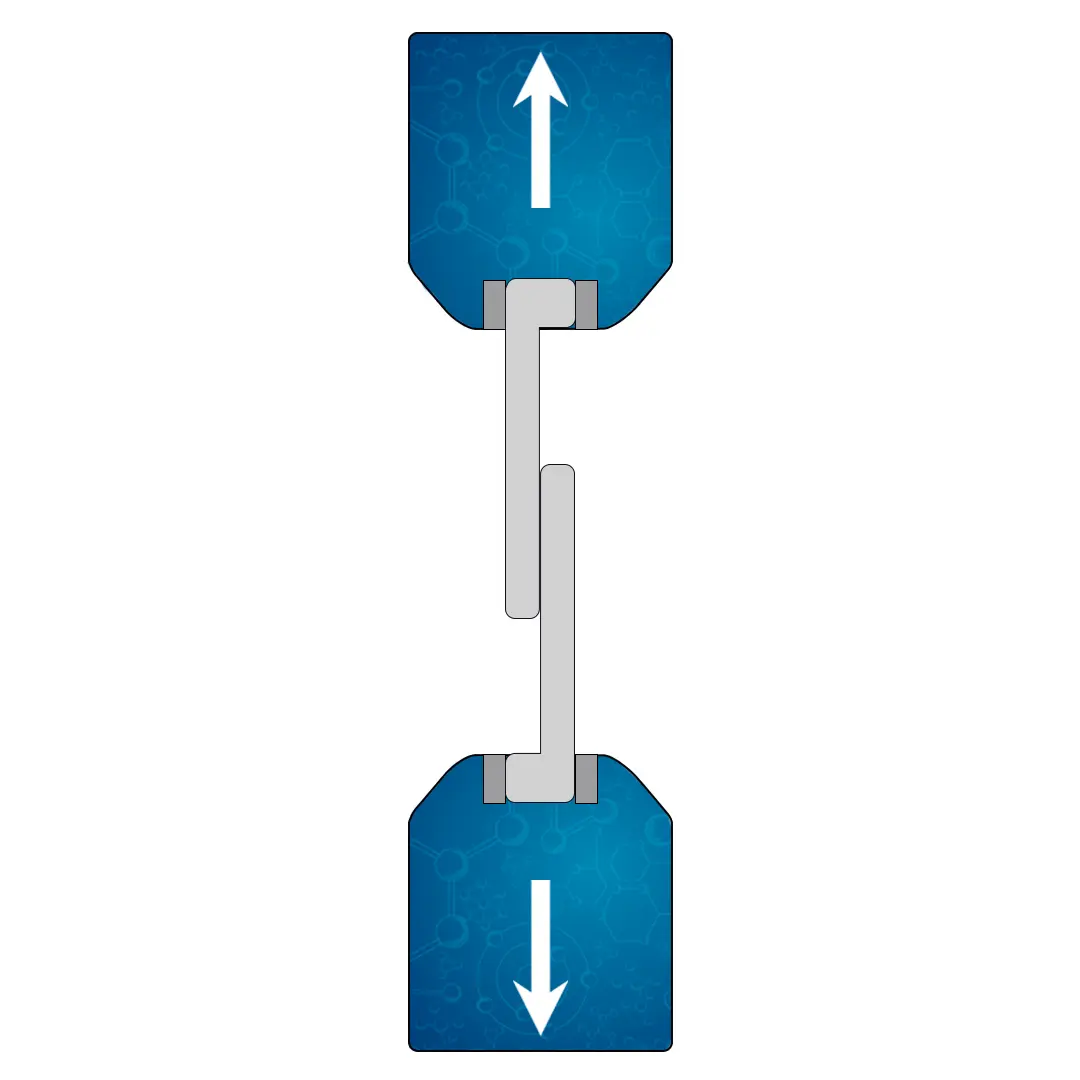

Bonding tests are conducted through various methods such as pull-off tests, shear tests, and peel tests. The process involves preparing samples, loading them into a testing machine like a Universal Testing Machine (UTM), applying force, and analyzing the data.

What is the bond strength test?

The bond strength test measures the force required to separate two bonded materials. It assesses both adhesive (between different materials) and cohesive (within the material itself) strengths.

What is a bond test in electrical?

In electrical contexts, a bond test refers to testing the electrical continuity between grounding devices to ensure safety and proper functioning of electrical systems.

What are the different types of bond test?

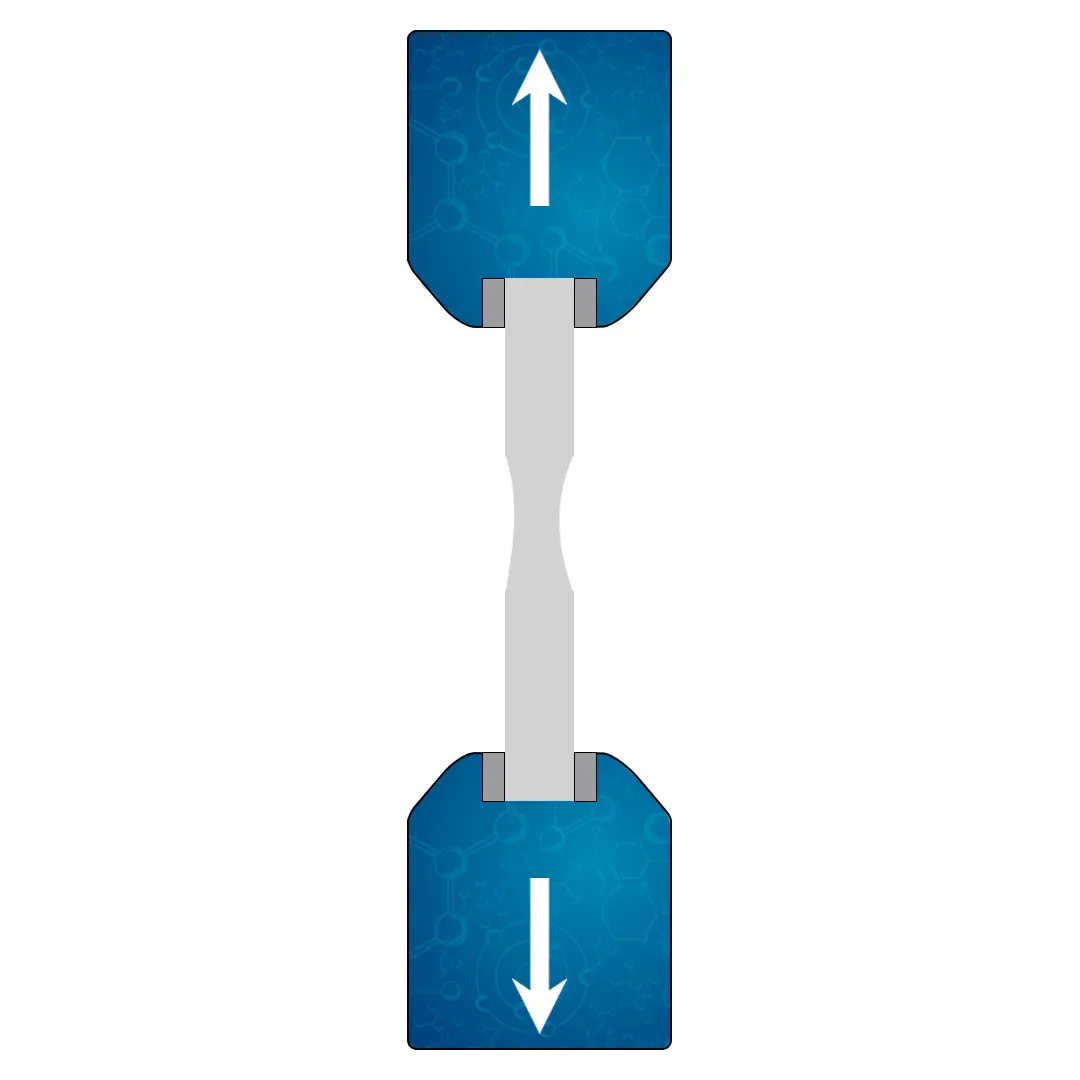

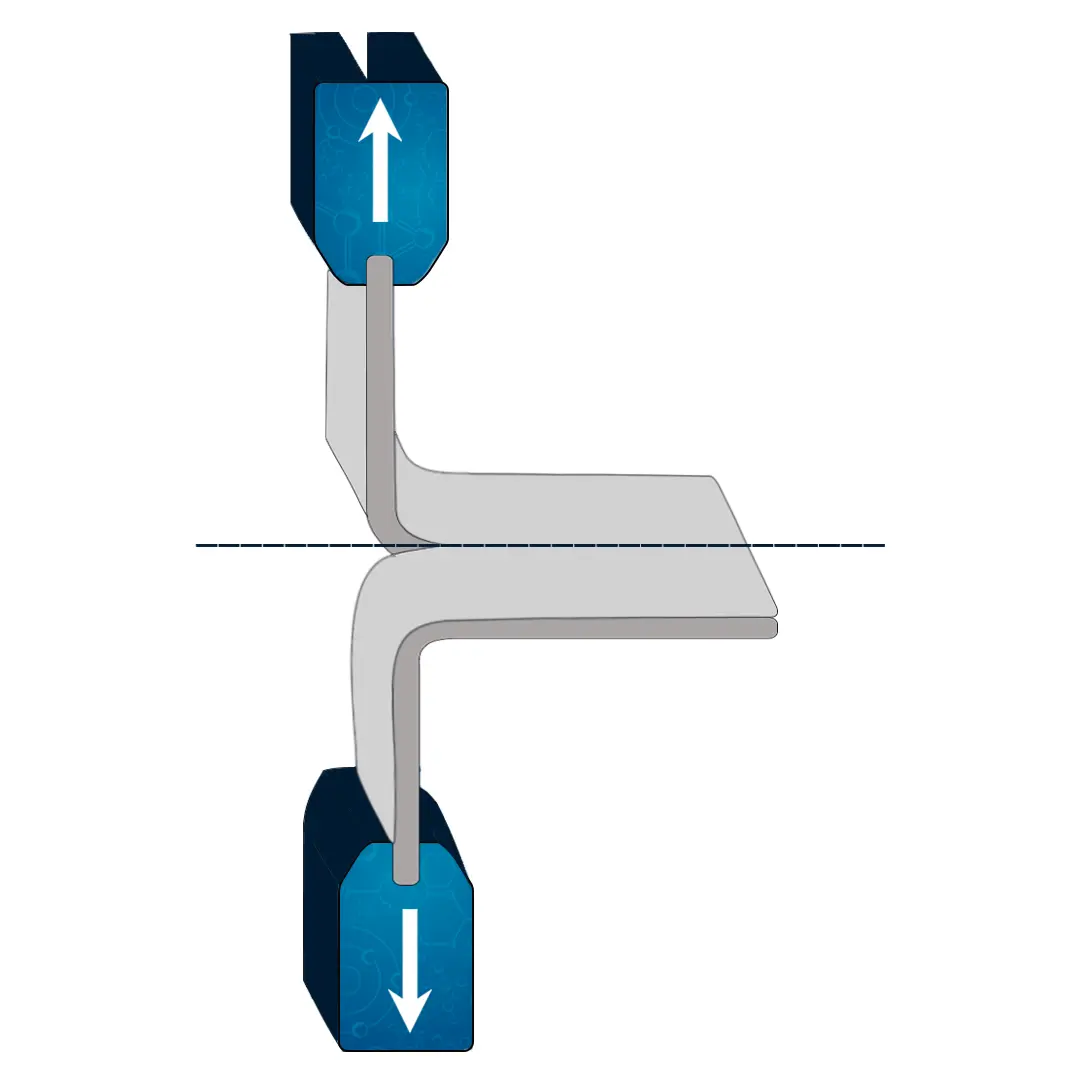

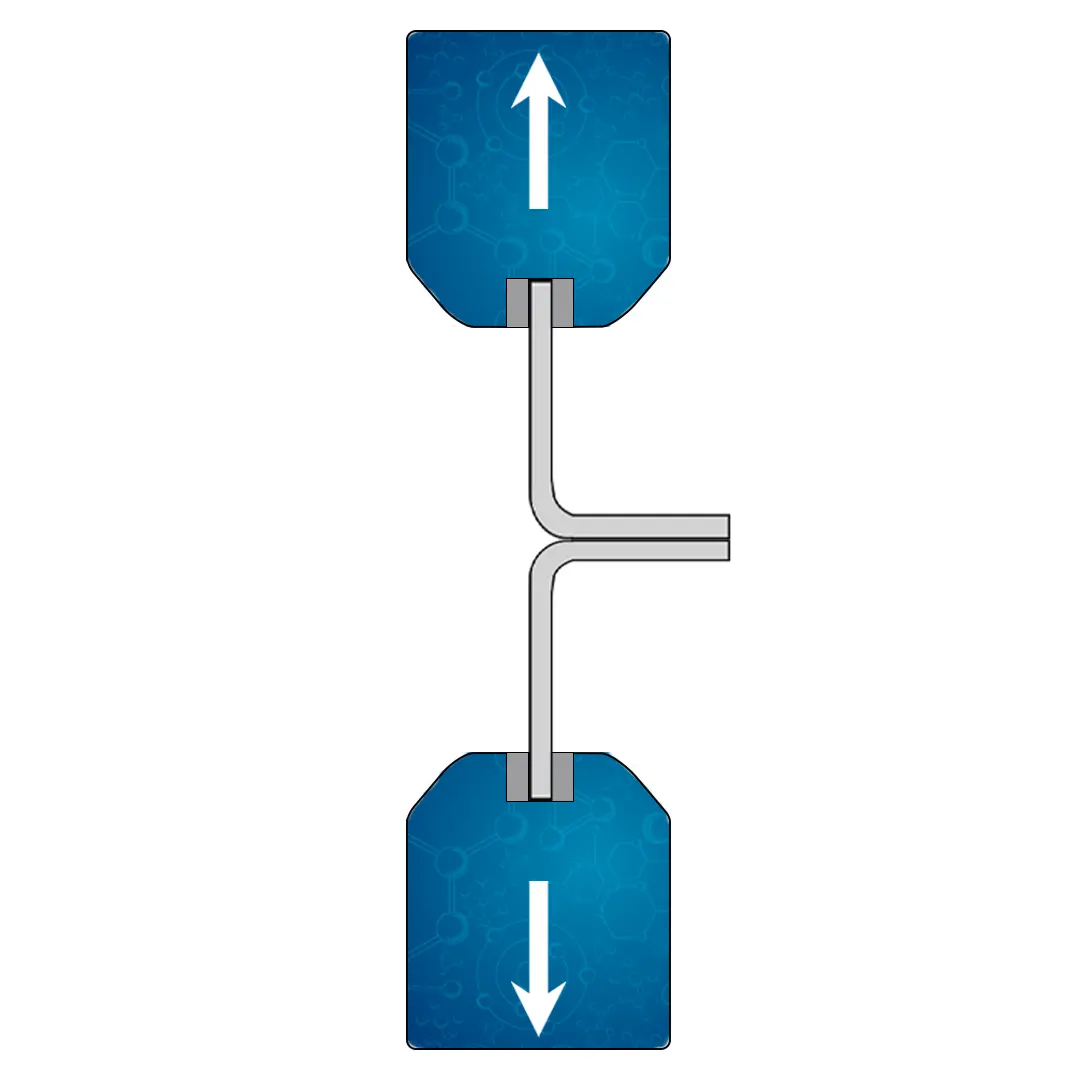

The main types include the pull-off test, shear test, and peel test, each measuring different aspects of bond strength.

What is bonding vs grounding?

Bonding refers to connecting electrical conductive parts to maintain the same electric potential, while grounding refers to connecting the electrical system to the earth. Bonding ensures continuity, while grounding protects against electrical shocks.

What are the three types of bonding?

The three primary types of chemical bonding are covalent (sharing electrons), ionic (transferring electrons), and metallic (pooled electrons).

How can you detect bonding failure?

Bonding failure can be detected through visual inspection, non-destructive testing, or performing a bonding test to evaluate the strength and identify weak areas.

What are the steps in the bonding process?

Typical steps include selecting the appropriate test method, preparing the samples, loading them into the testing apparatus, applying controlled forces, monitoring the process, collecting data, and analyzing the results.

How to do an earth bonding test?

Earth bonding tests are performed using specialized equipment to measure resistance between grounding connections and the earth, ensuring effective grounding of electrical systems.

What is the strongest bond strength?

Generally, covalent bonds are considered the strongest chemical bonds due to the shared electrons that create a robust connection between atoms.

What is average bond strength?

Average bond strength is the mean value of bond strengths in a material or structure, providing a generalized understanding of its overall bonding capability.

What is a tensile bond test?

A tensile bond test specifically measures the ability of bonded materials to resist forces that pull them apart. It’s commonly used to assess adhesives and coatings.

What bonds are strongest to weakest?

In general, the order of strength from strongest to weakest is covalent bonds, metallic bonds, and ionic bonds.

What are the two basic types of bonding?

The two basic types of chemical bonding are covalent, where electrons are shared, and ionic, where electrons are transferred.

What are the two primary types of bonding?

In a broad sense, chemical bonding (ionic, covalent, and metallic) and physical bonding (like Van der Waals forces) are the two primary types.

What is the basic of bonding?

Bonding is fundamentally about the interaction of atoms through the sharing, transferring, or pooling of electrons to create a stable connection.

What are the primary types of bonds?

The primary types of chemical bonds are covalent, ionic, and metallic bonds.

What are the characteristics of a bond?

Bond characteristics include the bond strength, bond length (distance between bonded atoms), bond energy (energy required to break the bond), and bond polarity (distribution of electrical charge).

See more relevant posts

TENSILE TEST

Tensile testing is a crucial mechanical test used to evaluate the strength and ductility of materials. It involves applying a controlled force. See more

COMPRESSION TEST

Compression testing is a fundamental evaluation method employed to assess a material's ability to withstand compressive forces. See more

SHEAR TEST

Shear testing examines a material's response to forces acting parallel to its surface. By applying a force that causes one part of the material. See more

BEND TEST

Bend testing is a mechanical test that determines a material's flexibility and resistance to fracture under bending forces. See more

FLEXURAL TEST

Flexural testing, also known as the three-point bend test, is employed to measure a material's resistance to bending or flexural stress. See more

FRICTION TEST

Coefficient of friction test measures the amount of resistance between two surfaces in contact when one moves relative to the other. See more

TEAR TEST

Tear test determines a material's resistance to tearing forces, often encountered in applications involving thin films, fabrics. See more

PEEL TEST

Peel testing evaluates the strength of adhesion between two materials, typically an adhesive and a substrate. The test involves separating. See more

BOND TEST

Bond test measures the strength of a bond between two materials. It's used in adhesive and weld test. It helps in determining the reliability of joints and interfaces. See more

INDENTATION TEST

Indentation Force Deflection (IFD) is used to characterize the cushioning or compressive properties of a material, especially foams and soft polymers. See more

FRACTURE TEST

Fracture toughness is a material's ability to resist crack propagation. This property is vital for assessing a material's suitability for applications where structural. See more

PUNCTURE TEST

Puncture test examines a material's ability to withstand penetration by sharp objects or forces. This test to evaluate puncture strength and design materials. See more

CRUSH TEST

Crush resistance test measures a material's ability to resist deformation, particularly in terms of compressive force. See more

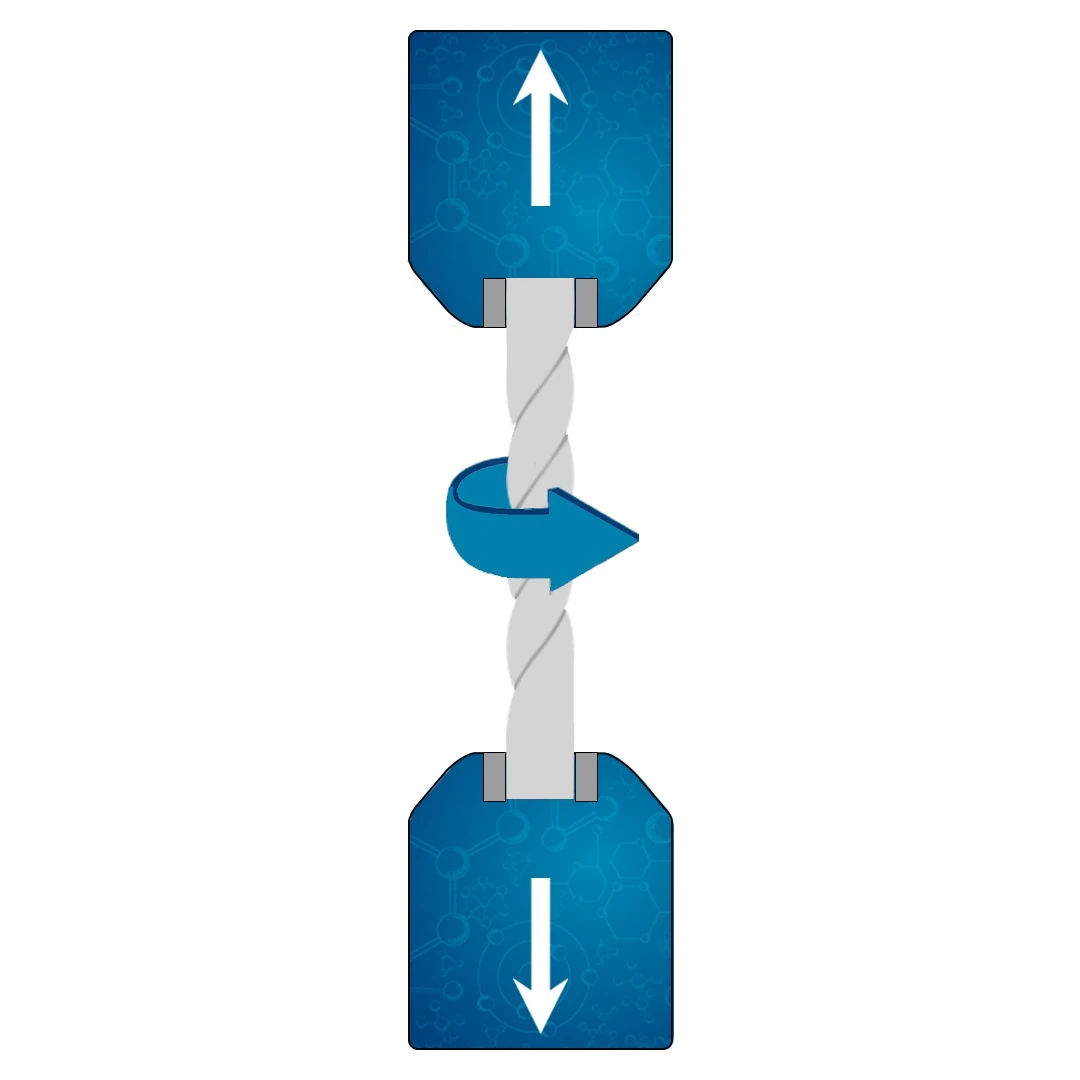

TORSION TEST

Torsion testing is a critical method in materials engineering, examining how products and materials behave under twisting forces. See more

AXIAL TORSION TEST

Axial torsion test examines a material's behavior when subjected to simultaneous axial and torsional loads. This test to study shear stress. See more

FATIGUE TEST

Fatigue Testing is the evaluation of a material's endurance and failure under repeated stress and cyclic loading conditions. See more.

Author: Mardoqueu M. Costa (Entrepreneur, researcher and writer). I have been working for several years in materials science and engineering and biomedical engineering with emphasis on Entrepreneurship. My focus is on the development of equipment, software, mechanical tests, and the evaluation and creation of new businesses. As a researcher and writer, I have contributed to scientific publications and patents, also working as a technical-scientific consultant for several companies. This integrated approach reflects my commitment to innovation and impact in the technology industry.

Contact us

Phones:

+1 (781) 328 - 2010

sales@biopdi.com

Address:

2 Burlington Woods Dr, Burlington, Massachusetts, United States