Understanding Indentation Force Deflection Test: A Comprehensive Guide

In the following article, we will explore the comprehensive details related to the Indentation Force Deflection (IFD) test. This in-depth study will encompass various aspects of the test including its definition, importance, advantages, types, properties, calculations, Universal Testing Machine components, procedures, data obtained, standards, applications, and additional insights. The field of engineering and material science sees the IFD test as a vital element, and this article will elucidate why.

What is the Indentation Force Deflection?

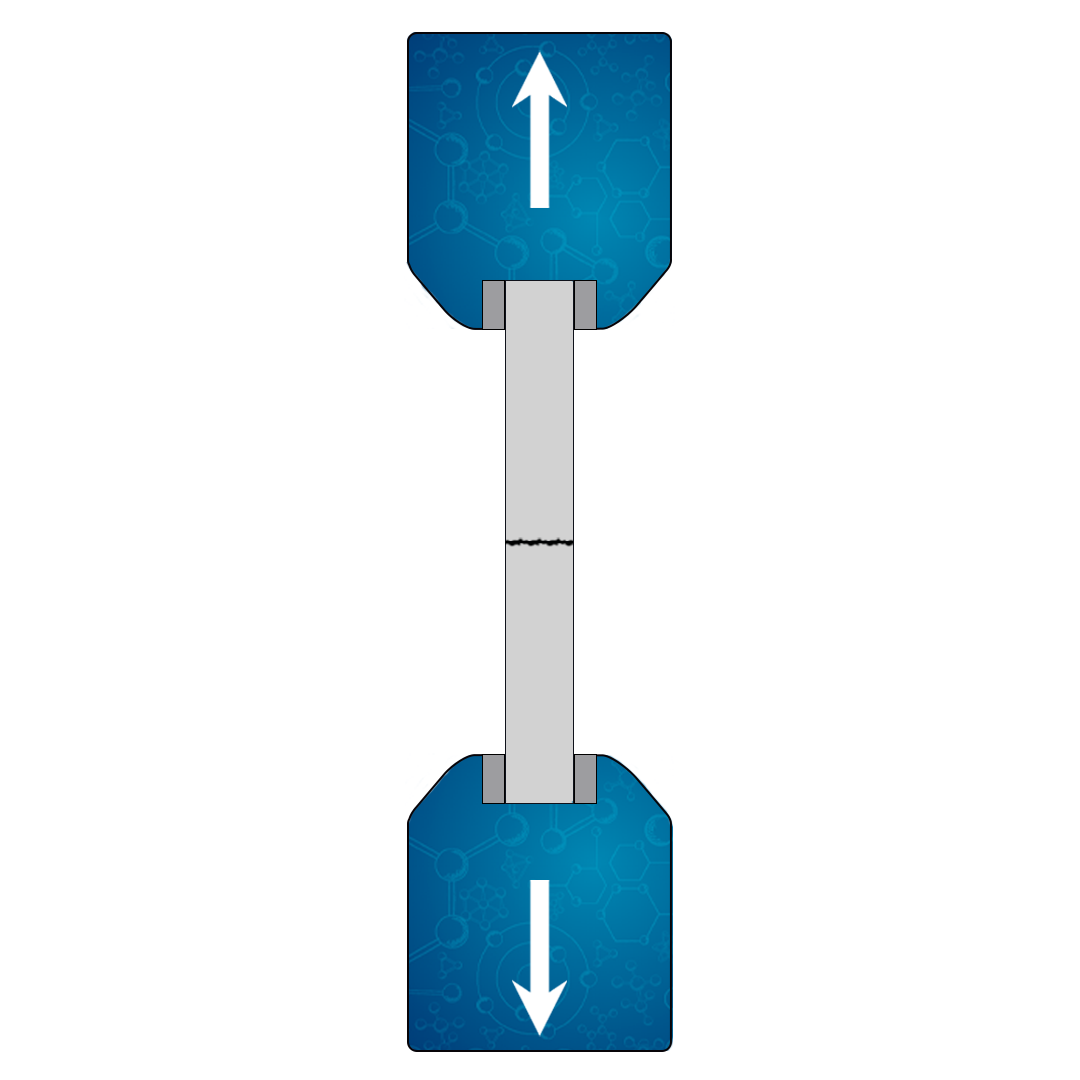

Indentation Force Deflection (IFD) is a measure used to describe the hardness or softness of a material, particularly in the context of foams and cushioning materials. It’s a critical parameter in assessing the comfort and support qualities of these materials.

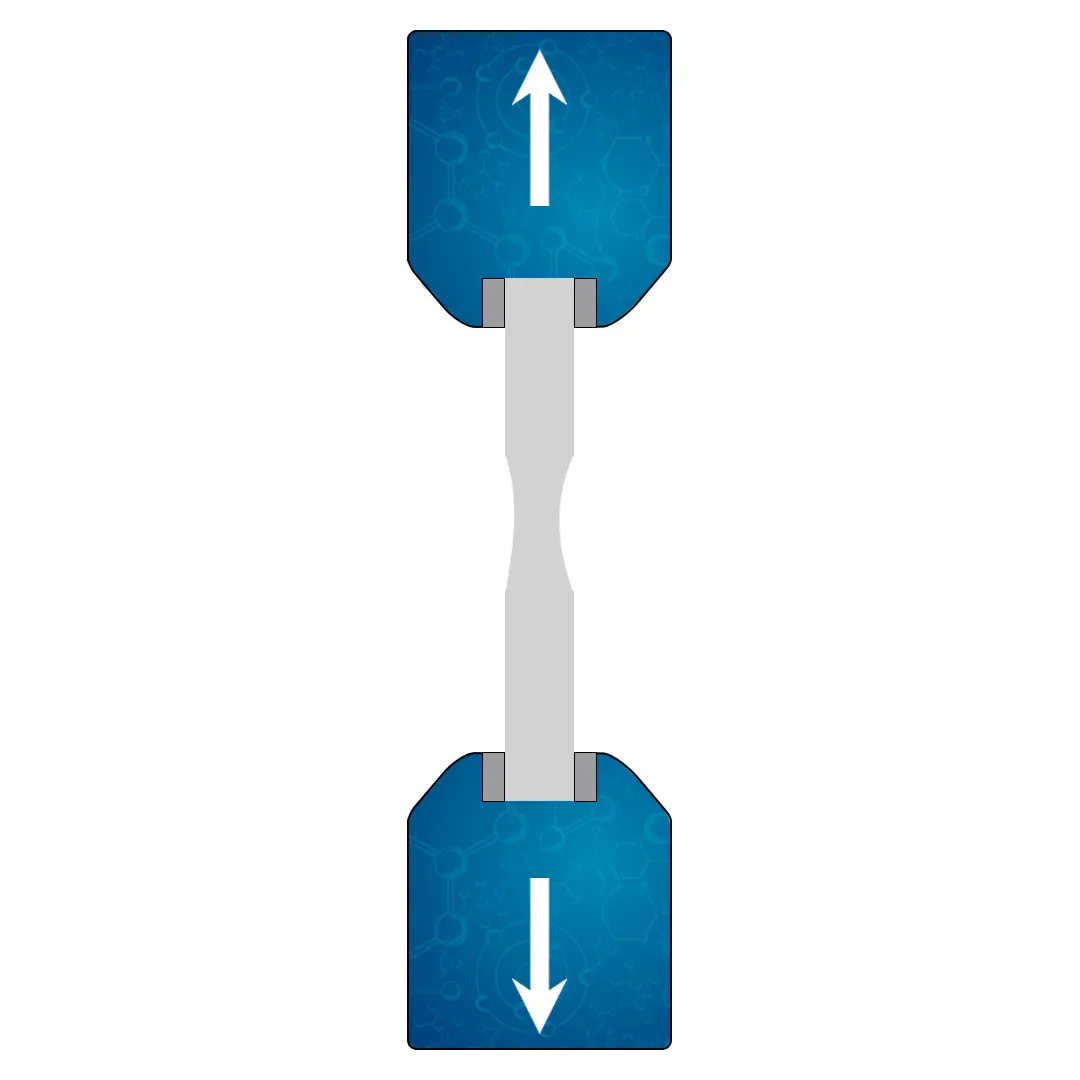

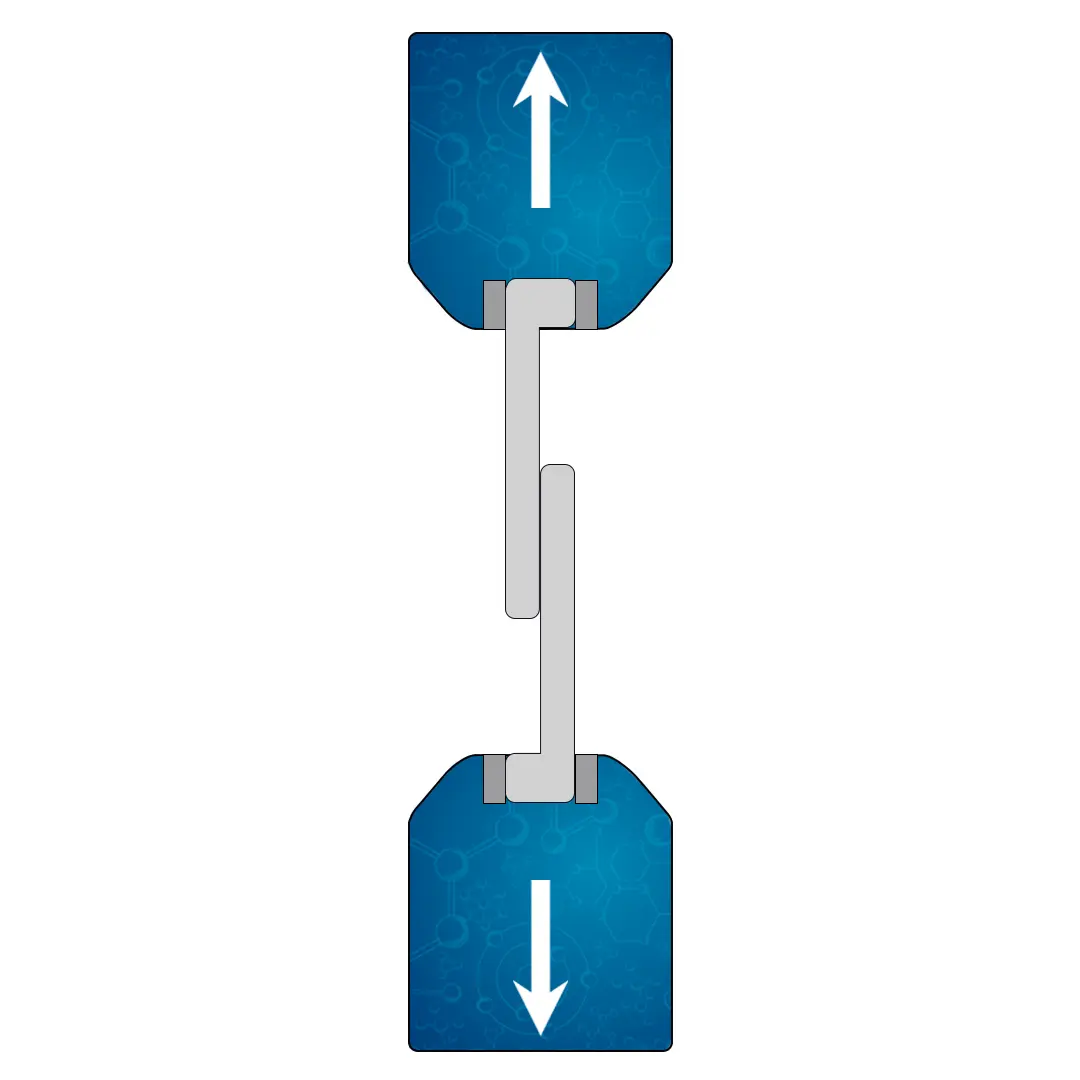

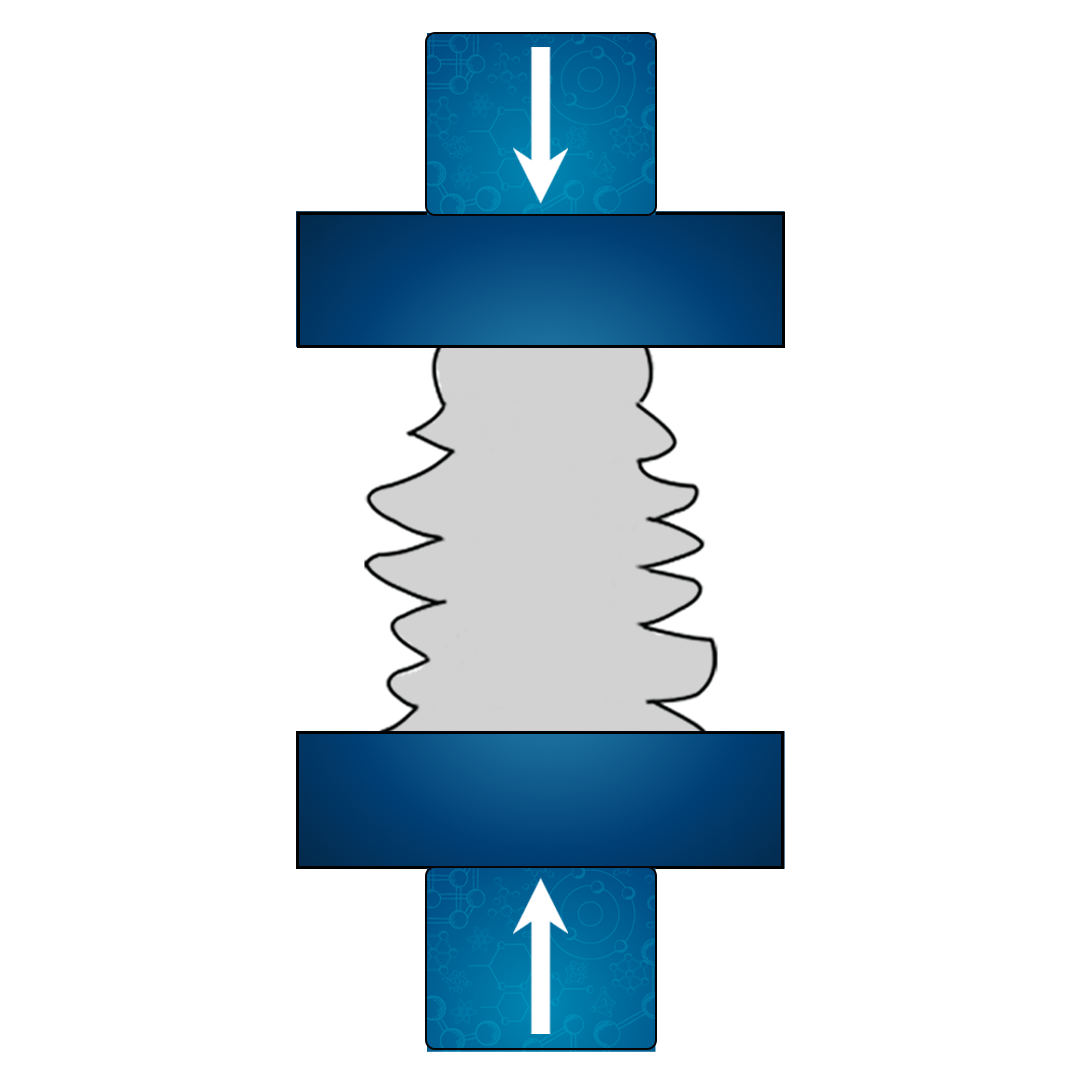

In the IFD test, a standardized indenter compresses the material to a specific percentage of its initial thickness, and the force required to achieve this deflection is measured. The result, expressed in units such as pounds or Newtons, represents the material’s resistance to indentation and, by extension, its firmness.

IFD values are widely used in various industries, including furniture manufacturing, automotive seating, and mattress production, to ensure products meet specific comfort and performance standards. Different materials will have different IFD values, allowing manufacturers to choose materials with the desired characteristics for their particular application.

What is the Indentation Load Deflection?

Indentation Load Deflection (ILD) is a term that is synonymous with Indentation Force Deflection (IFD). It refers to a standardized testing method used to determine the firmness or softness of a foam or cushioning material.

In the ILD test, a specific force is applied to compress the material by a standardized indenter, and the load required to achieve a certain level of deflection (such as 25% or 40% of the original thickness) is measured. The result is typically expressed in units like pounds or kilograms and represents the material’s resistance to indentation.

The ILD test provides critical insights into the performance characteristics of foams, enabling manufacturers and quality control professionals to evaluate how the material will respond under load. It is a common standard used in various industries, from furniture and bedding to automotive interiors, to ensure that products meet specific comfort and durability requirements.

What is the Indentation Force Deflection Test?

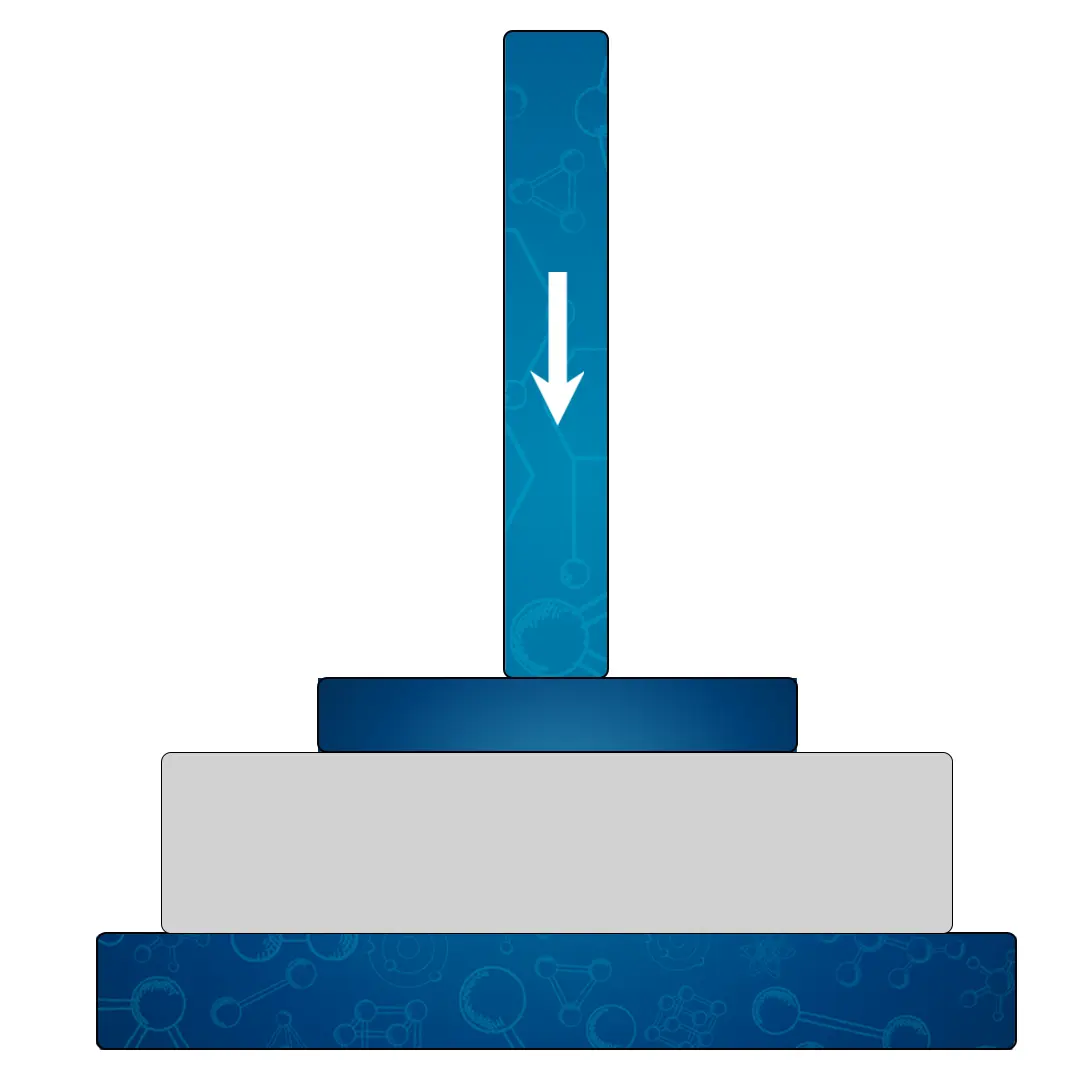

The IFD test is a method to determine the softness or firmness of a material, specifically foam or cushioning materials. The test involves compressing the material with a standardized indenter to a certain percentage of its original thickness and measuring the force required to do so.

Indentation Force Deflection Formula

The IFD is calculated using the formula:

where F is the force applied, and A is the area of the indenter’s face in contact with the material.

Importance of Indentation Force Deflection Test

The IFD test is vital for assessing material characteristics such as comfort, resilience, and durability. It is widely used in industries related to furniture, automotive seats, mattresses, and various consumer products.

Advantages of Using the Indentation Force Deflection Test

- Standardized Measurement: Provides a consistent and standardized way to measure material softness.

- Versatility: Applicable to various types of foams and cushioning materials.

- Quality Control: Essential for maintaining quality standards in manufacturing.

- Material Selection: Aids in choosing the right materials for specific applications.

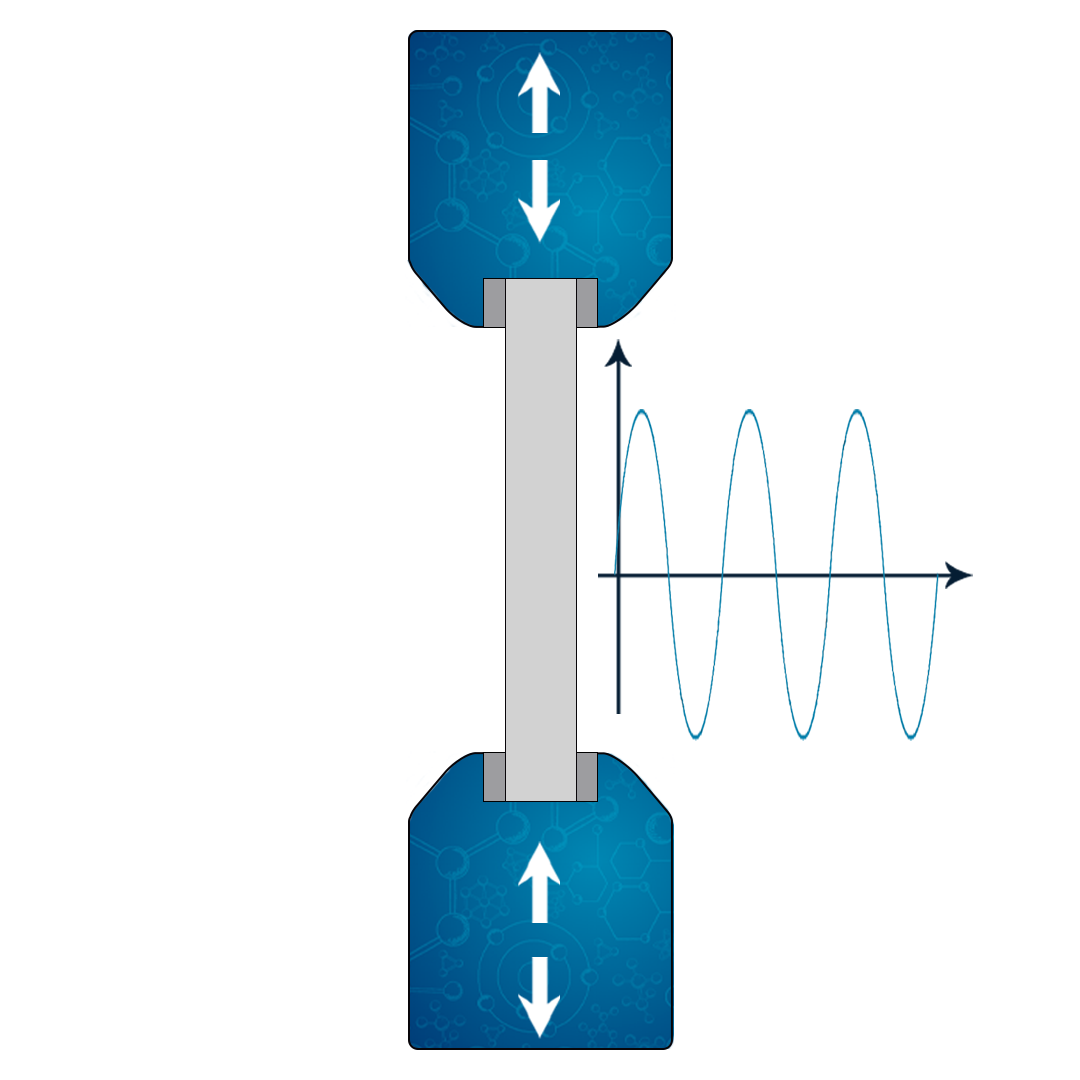

Types of Indentation Force Deflection Test

- Constant Rate of Penetration (CRP): Measures the force at specific penetration levels.

- Constant Load Level (CLL): Measures the deflection under a constant load.

Properties Obtained in the Indentation Force Deflection Test

- Hardness: Provides an insight into how soft or hard the material feels.

- Resilience: Measures the ability of the material to return to its original shape after deformation.

- Comfort Index: Assesses the comfort level of foam or cushioning material.

How to Calculate the Indentation Force Deflection Test

The IFD value is obtained by applying a specified force using a standardized indenter and then measuring the indentation or deflection. The force divided by the area of the indenter gives the IFD value in units of pressure (e.g., Pascals).

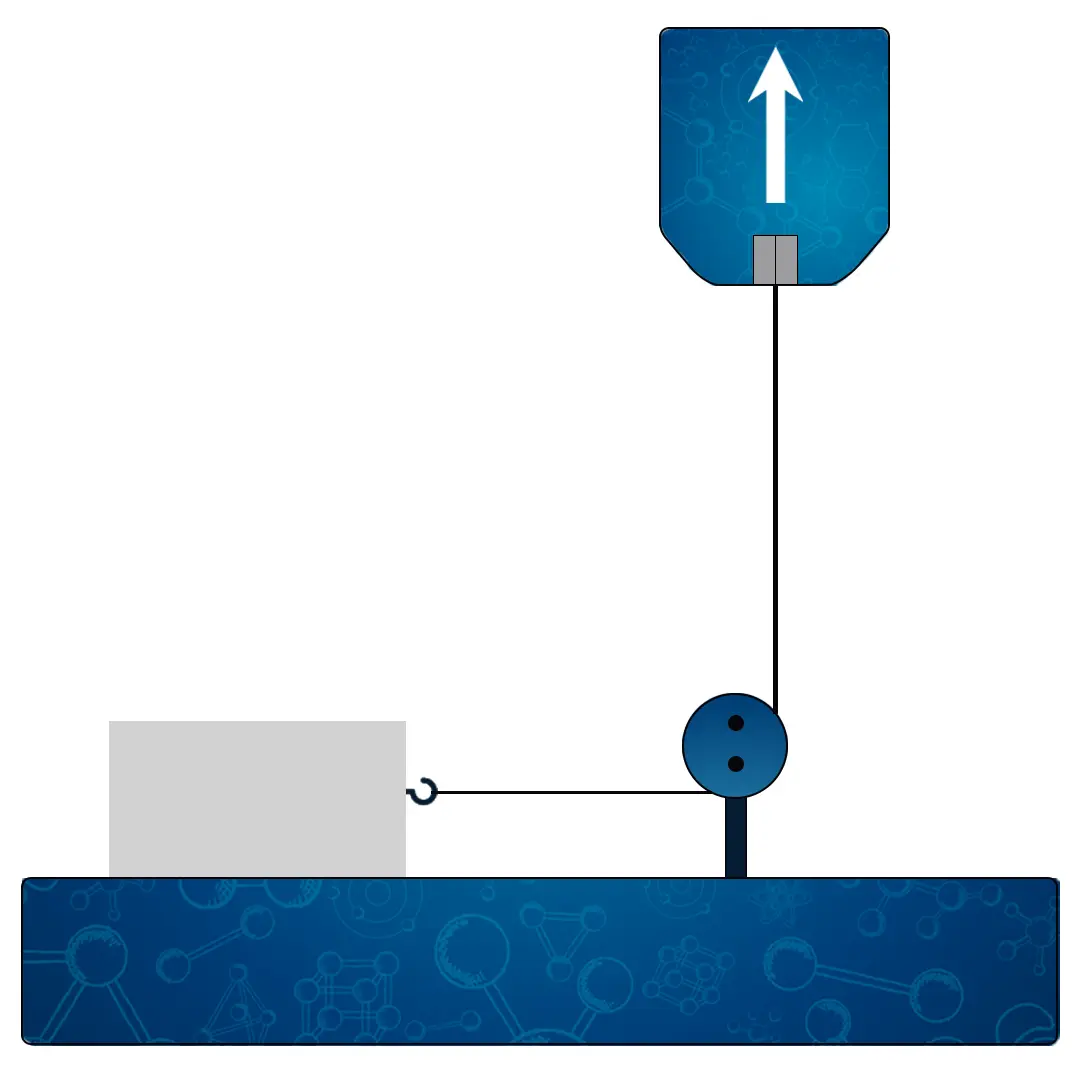

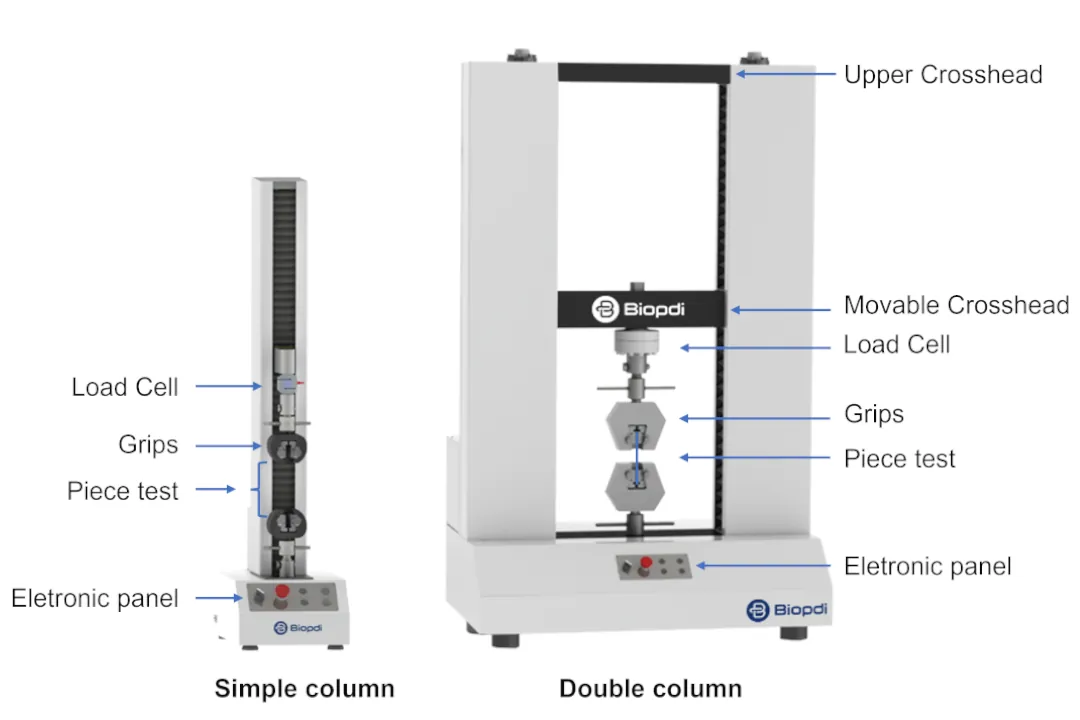

Universal testing machine used in indentation force deflection test

A Universal Testing Machine (UTM), also known as a universal tester, materials testing machine, or tensile testing machine, is a crucial piece of equipment in the field of material science and engineering. It’s versatile enough to perform various types of mechanical tests, including indentation force deflection.

Below are the essential parts and components of a UTM used in indentation force deflection:

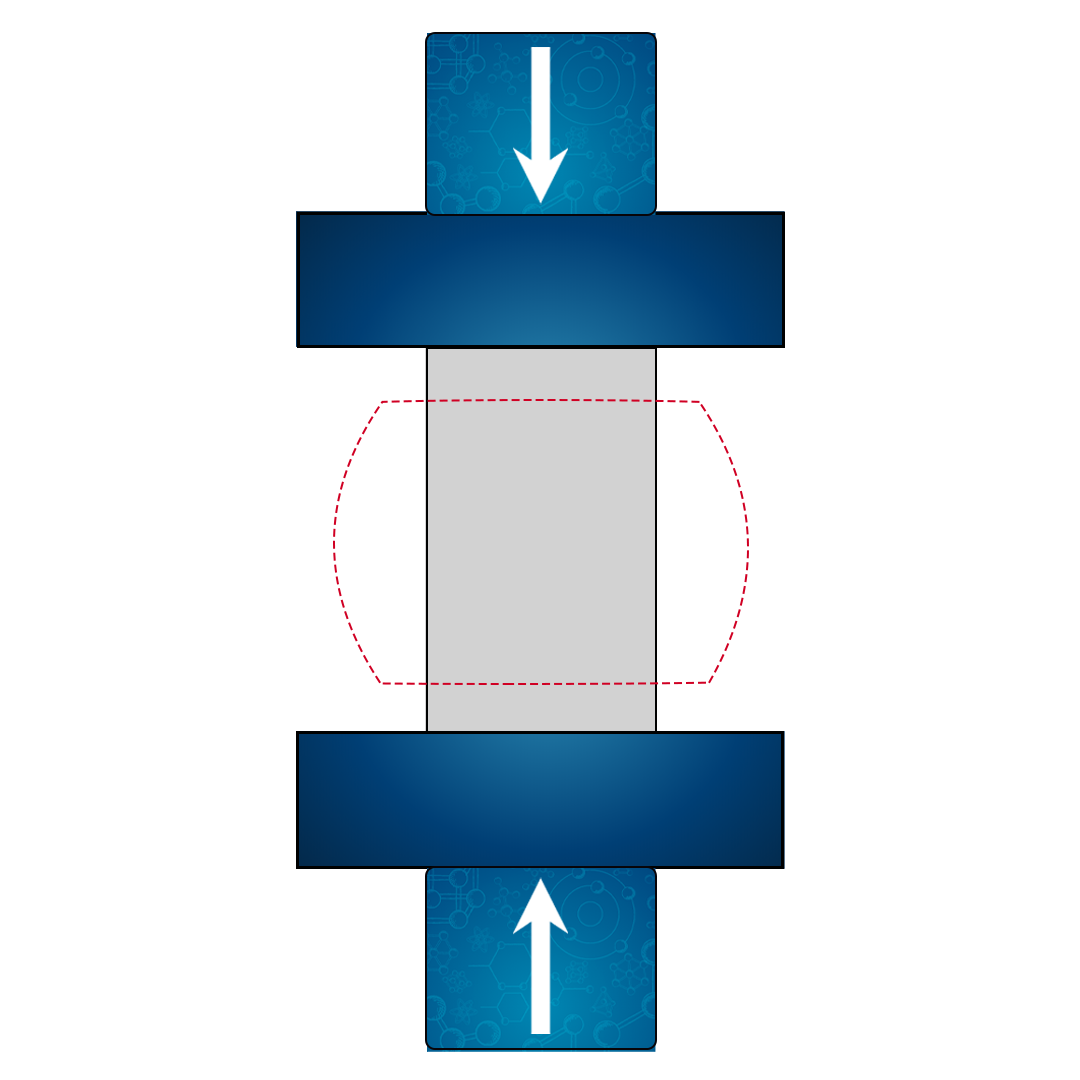

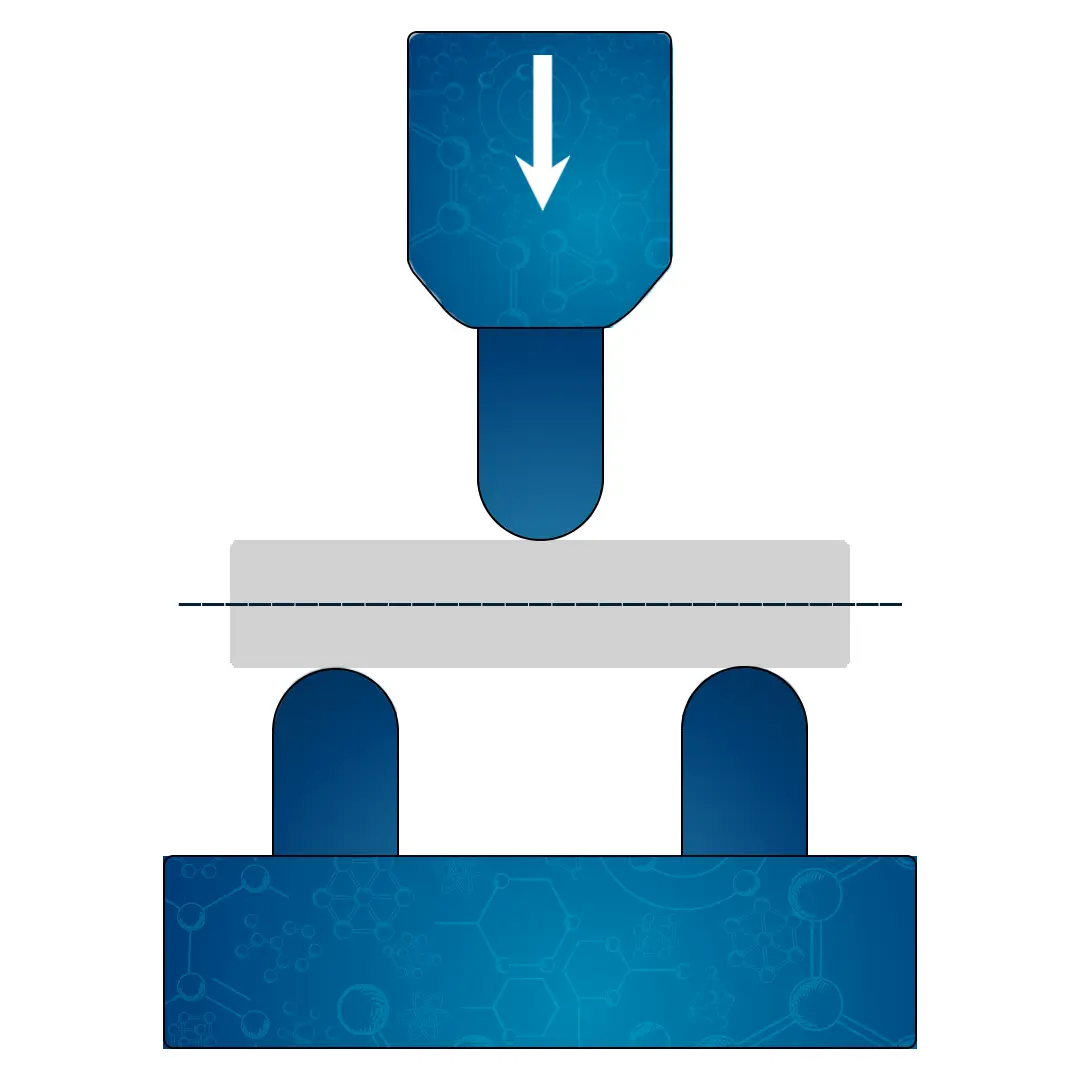

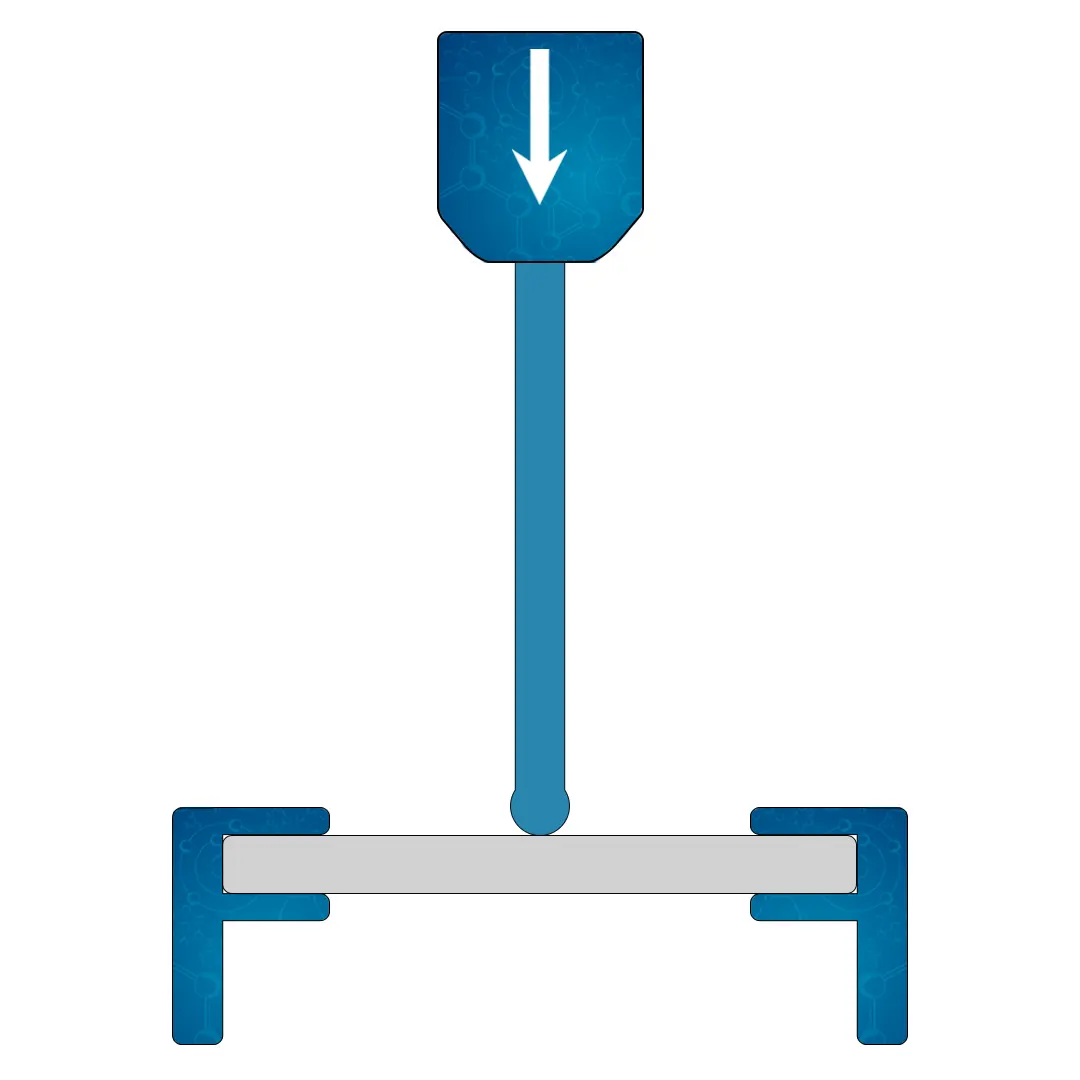

- Load Frame: The load frame is the primary structure of the UTM, typically composed of two strong vertical columns connected by a top and bottom crosshead. This rigid structure is designed to accommodate the high stress generated during testing.

- Crossheads: These are positioned at the top and bottom of the load frame. The upper crosshead is usually stationary, while the lower crosshead can be adjusted depending on the length of the specimen.

- Load Cell: This is a transducer that converts force into an electrical signal, allowing the UTM to measure the load applied to the specimen. Its accurate calibration is crucial for precise testing.

- Actuator: Typically driven by hydraulic, mechanical, or electromechanical means, the actuator applies the required load on the specimen. In some machines, the actuator’s position is adjustable to accommodate specimens of different sizes.

- Grips/ Fixtures: These hold the test specimen in place during testing. For shear testing, a specific shear test fixture might be used. The grips/fixtures must be chosen carefully to ensure they don’t slip or induce additional stresses that could interfere with the test results.

- Extensometer: This device is used to measure the deformation or strain in the test specimen during the application of force.

- Control Unit: This component controls the speed and direction of the load, the parameters of the test, and other variables. In modern UTMs, the control unit is typically a computer running specialized software.

- Output Device: This could be a computer monitor or a printer that provides a visual representation of the test results, often in the form of a stress-strain graph or a detailed test report.

- Safety Guards: These are essential to protect operators from flying debris in case of a specimen fracture or fixture failure.

Each of these components plays a critical role in the functioning of a UTM. For accurate and reliable results, the UTM should be regularly calibrated and maintained according to the manufacturer’s guidelines and relevant industry standards.

Universal Testing Machine used in the shear test

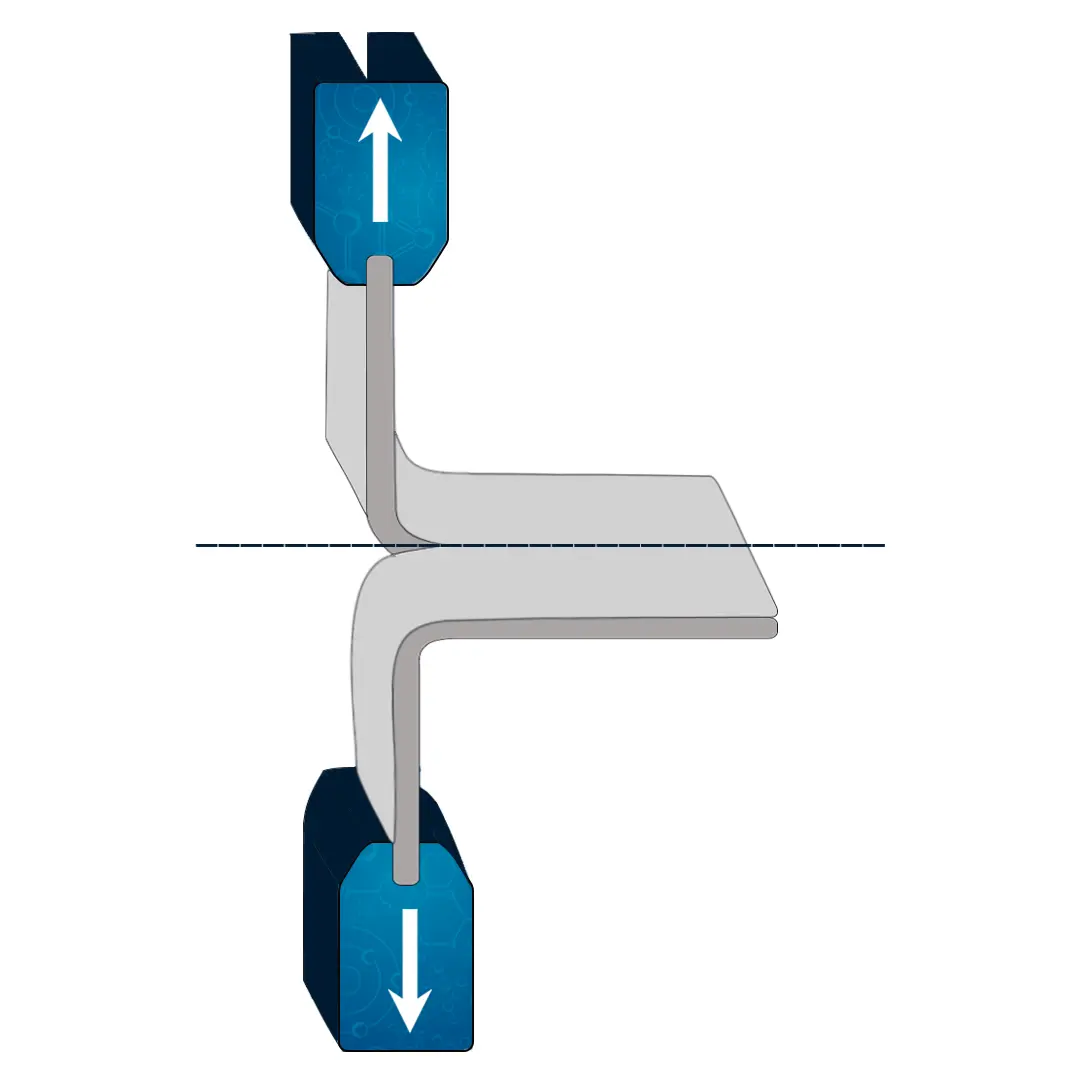

Procedures for Conducting an IFD Test Using a Universal Testing Machine

- Preparation: The sample is prepared to the required dimensions.

- Calibration: The machine is calibrated according to standards.

- Placement: The sample is placed on the base plate.

- Compression: The indenter compresses the sample to specific levels.

- Measurement: The force and deflection are measured and recorded.

- Analysis: The IFD value is calculated, and the report is generated.

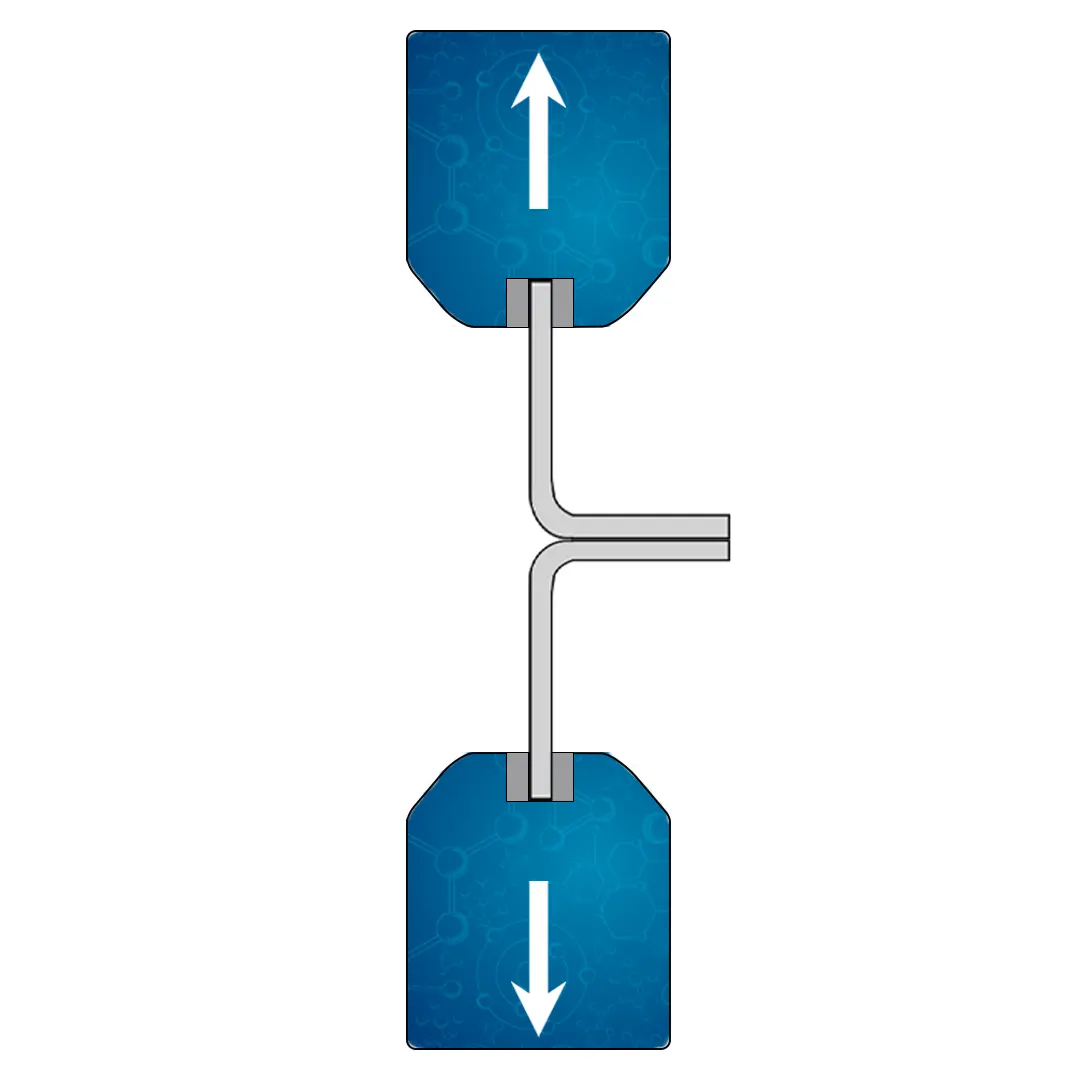

Data Obtained in the IFD Test Using the Universal Testing Machine

- Force Values: The applied force at different deflection levels.

- Deflection Values: The amount of deflection at different force levels.

- IFD Value: The calculated IFD value representing the material’s hardness or softness.

Samples/Specimens Used for IFD Test in Universal Testing Machine

Common samples include polyurethane foam, memory foam, latex foam, and other cushioning materials, often used in mattresses, seating, and automotive interiors.

Standards for IFD Test

The Indentation Force Deflection test is performed according to several international standards. Depending on the specific requirements of the industry or material being tested, different standards might be followed. Here are five major ISO standards and five ASTM standards commonly associated with IFD testing:

ISO Standards

- ISO 2439 – Flexible Cellular Polymeric Materials – Determination of Hardness (Indentation Technique). This standard specifies methods for determining indentation hardness, with particular emphasis on flexible cellular materials.

- ISO 3386-1 – Polymeric Materials, Cellular, Flexible – Determination of Stress-Strain Characteristics in Compression – Part 1: Low-Density Materials. This part of ISO 3386 applies to flexible cellular polymeric materials, providing methods for determining stress-strain characteristics under compression.

- ISO 8307 – Flexible Cellular Polymeric Materials – Determination of Resilience by Ball Rebound. Though focused on resilience, this standard is often associated with IFD testing as part of a broader assessment of material properties.

- ISO 1856 – Flexible Cellular Polymeric Materials – Determination of Compression Set. This standard details the method for determining the compression set characteristics of flexible cellular materials.

- ISO 7214 – Flexible Cellular Polymeric Materials, Laboratory Assessment of Odour of Polyether Foam. While not directly related to IFD, this standard is relevant to overall material evaluation and is sometimes used in conjunction with IFD testing.

ASTM Standards

- ASTM D3574 – Standard Test Methods for Flexible Cellular Materials – Slab, Bonded, and Molded Urethane Foams. This standard includes a method specifically for determining the IFD of urethane foams.

- ASTM D575 – Standard Test Methods for Rubber Properties in Compression. While intended for rubber, these test methods can be adapted for certain cellular materials, and IFD tests may be conducted using these guidelines.

- ASTM D1056 – Standard Specification for Flexible Cellular Materials – Sponge or Expanded Rubber. This specification addresses the classification and testing of cellular materials, including IFD measurement methods.

- ASTM D1621 – Standard Test Method for Compressive Properties Of Rigid Cellular Plastics. Though designed for rigid foams, this standard can be related to IFD testing as part of a comprehensive analysis of cellular materials.

- ASTM D1817 – Standard Test Method for Rubber Chemicals Density. Though not directly related to IFD, it might be used in conjunction with IFD testing for a complete understanding of material properties.

These standards help ensure that IFD tests are conducted consistently and that results are comparable across different laboratories and industries. They provide detailed guidance on apparatus, sample preparation, test procedure, and reporting, ensuring that the IFD value accurately reflects the material’s characteristics.

Main Applications of the IFD Test

- Furniture Industry: Evaluating comfort and durability of cushions.

- Automotive Industry: Assessing the comfort of automotive seats.

- Mattress Industry: Determining the right firmness level for mattresses.

- Medical Industry: Customizing medical cushions and supports.

- Consumer Goods: Ensuring quality control in various foam products.

Additional Information about IFD Test

The IFD test is only one aspect of characterizing foams and cushioning materials. Other tests like resilience, tensile strength, and fatigue testing are also vital for a complete understanding. IFD test methods might vary based on specific industry standards or individual company guidelines.

Conclusion

The Indentation Force Deflection (IFD) test is an essential tool in material science and engineering, particularly in the characterization of foams and cushioning materials. From determining hardness to ensuring comfort and resilience, the IFD test offers valuable insights across various industries. Its significance extends to quality control, product development, and material selection, making it a pivotal aspect in manufacturing and production processes.

FAQs

What is indentation load deflection?

Indentation Load Deflection (ILD) refers to a standardized test to measure the hardness or softness of foam and cushioning materials. It’s synonymous with Indentation Force Deflection (IFD) and determines the force required to compress the material to a specific percentage of its thickness.

How do you measure indentation force deflection?

IFD is measured by compressing a foam sample with a standardized indenter to a specific percentage of its original thickness. The force required to achieve this deflection is recorded, and the IFD value is calculated.

What is the unit of indentation force deflection?

The unit of IFD can be expressed in pounds (lbs) or Newtons (N), depending on the standard or industry practice.

What is the IFD test method?

The IFD test method involves preparing a material sample, compressing it using a standardized indenter to a predetermined deflection, and then measuring the force required. Standards like ISO 2439 and ASTM D3574 outline the method in detail.

Is indentation the same as compression?

Indentation and compression are related but distinct. Indentation specifically refers to the force applied to create a deformation in a localized area, while compression refers to a force applied uniformly, causing a reduction in volume or thickness.

Is deflection the same as compression?

Deflection is the displacement or deformation of a material under load, while compression is the force causing that deflection. So, compression can lead to deflection, but they are not the same.

What is the difference between IFD and ILD?

IFD (Indentation Force Deflection) and ILD (Indentation Load Deflection) refer to the same test and are often used interchangeably. There is no difference between the two terms.

What is IFD for foam?

IFD for foam refers to the standard measurement of a foam’s resistance to indentation, reflecting its firmness or softness.

What does IFD stand for in foam?

IFD in foam stands for Indentation Force Deflection.

Is compression deflection the same as hardness?

Compression deflection measures how much a material deflects under a specific load, while hardness refers to the material’s resistance to deformation. They are related but not identical.

What is the deflection under compression?

Deflection under compression is the displacement or deformation experienced by a material when a compressive force is applied.

What is the IFD of foam firmness?

IFD is a measure of foam firmness, with higher IFD values indicating firmer foam and lower values indicating softer foam.

What is indentation load deflection foam firmness testing?

This refers to the testing method using ILD to determine the firmness of foam by measuring its resistance to indentation.

What is the standard for polyurethane foam testing?

Standards like ISO 2439 and ASTM D3574 are commonly used for testing polyurethane foam, including IFD measurements.

How do you measure indentation?

Indentation is measured using specific instruments and techniques to apply a standardized force to a material and recording the depth of the resulting indentation.

What is the indentation technique?

The indentation technique refers to the method of applying a known force to a localized area of a material to measure its hardness or resistance to deformation.

Why should you use indentation?

Indentation provides valuable insights into material properties such as hardness, elasticity, and resilience, essential for quality control, research, and development.

What are the three types of deflection?

Deflection can be categorized as elastic (temporary deformation), plastic (permanent deformation), or buckling (instability leading to sudden bending or twisting).

What is a deflection force?

A deflection force is the force applied to a material or structure, causing it to bend, deform, or displace.

What determines deflection?

Deflection is determined by factors such as the applied force, material properties (such as Young’s modulus), geometry, boundary conditions, and temperature.

See more relevant posts

TENSILE TEST

Tensile testing is a crucial mechanical test used to evaluate the strength and ductility of materials. It involves applying a controlled force. See more

COMPRESSION TEST

Compression testing is a fundamental evaluation method employed to assess a material's ability to withstand compressive forces. See more

SHEAR TEST

Shear testing examines a material's response to forces acting parallel to its surface. By applying a force that causes one part of the material. See more

BEND TEST

Bend testing is a mechanical test that determines a material's flexibility and resistance to fracture under bending forces. See more

FLEXURAL TEST

Flexural testing, also known as the three-point bend test, is employed to measure a material's resistance to bending or flexural stress. See more

FRICTION TEST

Coefficient of friction test measures the amount of resistance between two surfaces in contact when one moves relative to the other. See more

TEAR TEST

Tear test determines a material's resistance to tearing forces, often encountered in applications involving thin films, fabrics. See more

PEEL TEST

Peel testing evaluates the strength of adhesion between two materials, typically an adhesive and a substrate. The test involves separating. See more

BOND TEST

Bond test measures the strength of a bond between two materials. It's used in adhesive and weld test. It helps in determining the reliability of joints and interfaces. See more

INDENTATION TEST

Indentation Force Deflection (IFD) is used to characterize the cushioning or compressive properties of a material, especially foams and soft polymers. See more

FRACTURE TEST

Fracture toughness is a material's ability to resist crack propagation. This property is vital for assessing a material's suitability for applications where structural. See more

PUNCTURE TEST

Puncture test examines a material's ability to withstand penetration by sharp objects or forces. This test to evaluate puncture strength and design materials. See more

CRUSH TEST

Crush resistance test measures a material's ability to resist deformation, particularly in terms of compressive force. See more

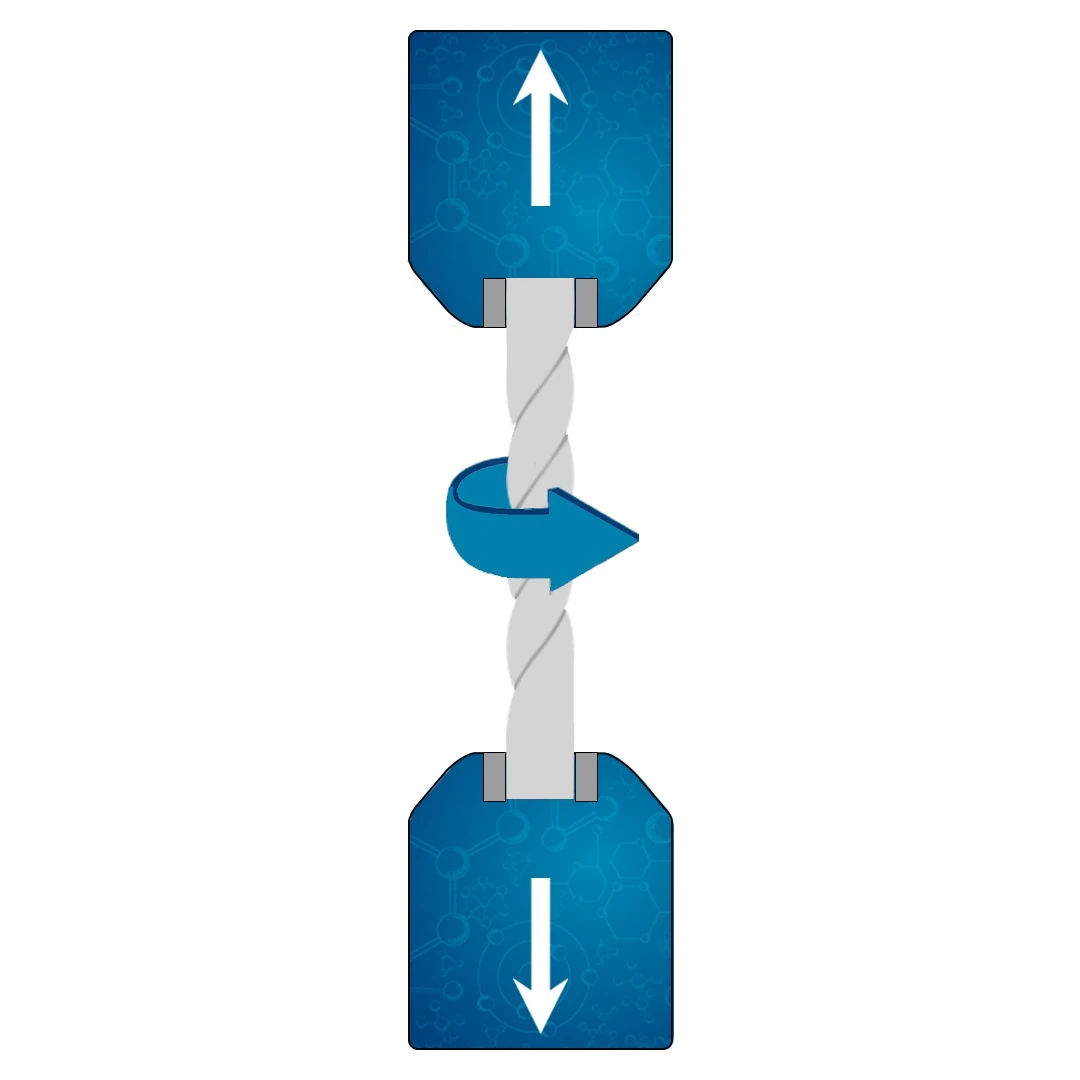

TORSION TEST

Torsion testing is a critical method in materials engineering, examining how products and materials behave under twisting forces. See more

AXIAL TORSION TEST

Axial torsion test examines a material's behavior when subjected to simultaneous axial and torsional loads. This test to study shear stress. See more

FATIGUE TEST

Fatigue Testing is the evaluation of a material's endurance and failure under repeated stress and cyclic loading conditions. See more.

Author: Mardoqueu M. Costa (Entrepreneur, researcher and writer). I have been working for several years in materials science and engineering and biomedical engineering with emphasis on Entrepreneurship. My focus is on the development of equipment, software, mechanical tests, and the evaluation and creation of new businesses. As a researcher and writer, I have contributed to scientific publications and patents, also working as a technical-scientific consultant for several companies. This integrated approach reflects my commitment to innovation and impact in the technology industry.

Contact us

Phones:

+1 (781) 328 - 2010

sales@biopdi.com

Address:

2 Burlington Woods Dr, Burlington, Massachusetts, United States