Universal Testing Machine

The Universal Testing Machine, also known as the Tensile Testing Machine, serves as a versatile tool capable of conducting tests on a wide range of materials. These materials encompass metals, concrete, rubbers, fabrics, vegetables, and many others, making it possible to assess the properties and characteristics of virtually any material.

The equipment excels in accurately performing tests on various types of specimens, prototypes, and even the final products themselves. As a result, the Universal Testing Machine finds utility in numerous fields and industries.

For instance, sectors such as Metalworking, civil construction, medicine, auto racing, clothing, and furniture have all achieved remarkable results by employing this instrument in their respective processes.

To gain a deeper understanding of this subject, I invite you to explore the article linked here. It will provide valuable insights into how material tests are carried out and the functioning of the Universal Testing Machine, shedding light on its wide-ranging applications across different industries.

Introduction

In January 2018, the online retail giant Amazon boasted an impressive inventory of 562 million distinct products available for purchase. In comparison, eBay, another major e-commerce platform, consistently offered over 1 billion products at any given time. Meanwhile, the Brazilian marketplace, Mercado Livre, had already announced an impressive 128 million different products by the end of 2015. This sheer diversity of products poses a fresh and significant challenge for the field of product and material engineering.

In the past, the variation in products was primarily centered around factors like price and functionality. However, the landscape has evolved, and now other crucial considerations come into play. Elements such as design, durability, and even the environmental and social impact of a product have a profound influence on its overall usefulness as a source of revenue for companies.

One of the key drivers behind the proliferation of diverse offerings lies in the evolution of the materials used in manufacturing. Through research and innovation, materials like steel have evolved to become more flexible and cost-effective. This advancement allowed the automobile industry to progress significantly. Additionally, the development of robust alloys has enabled the construction of taller, weather-resistant, and smarter buildings and towers, ushering in new possibilities and solutions in the construction sector.

Moreover, the creation of entirely new materials has sparked the emergence of novel industries and a wide array of products and applications. For example, the invention of superconductors gave birth to the revolutionary chip, which transformed the electronics industry and paved the way for the personal computer market. The continuous evolution of personal computers eventually led to the rise of smartphones, creating yet another dynamic market that has transformed the way we interact with technology.

In essence, the ever-changing landscape of materials and products continues to drive innovation across various industries. As we navigate this diverse and dynamic marketplace, engineering and design must adapt to the evolving demands of consumers and the global environment. Embracing these challenges with ingenuity and creativity paves the way for further advancements that shape the future of products and materials.

Figure 1: From the natural product to clay, to glass, to plastic, to PET, to aluminum and for design objects.

One fundamental question, however, remains: for any product to hold commercial value, it must perform as anticipated within the defined conditions of use.

Hence, expected performance entails not only functionality (delivering on promises made) but also safety (adhering to various international standards and laws that outline the fundamental characteristics regarding toxicity, flammability, and proper handling of the product). Additionally, durability (the product’s service life) significantly impacts its profitability and influences the consumer’s perception of its quality. Furthermore, disposal is a critical consideration, as laws and regulations govern each stage of a product’s lifecycle – from the extraction of its basic materials to its ultimate return to nature.

Figure 2: Functionality – leaving point A and arriving at point B

Therefore, a fundamental aspect in the manufacturing of any product is the testing phase. These tests can be conducted on the raw materials, individual components, the finished product, or even models of the final product.

One of the most crucial elements in product engineering is the utilization and selection of materials. This is not only because it determines the various stages of a product’s lifecycle, from acquisition to disposal, encompassing all manufacturing processes (along with their economic and environmental implications at each step), but also because the properties of the materials employed will shape the manufacturing processes themselves.

What is a Universal Testing Machine?

A Universal Testing Machine (UTM), also known as a universal tester, materials testing machine, or tensometer, is a device used to test the tensile strength and compressive strength of materials. It is named so because it can perform many standard tensile and compression tests on materials, components, and structures.

The UTM is a versatile machine capable of performing multiple tests on a wide range of materials. These tests include, but are not limited to, tensile, compressive, bending or flexural, shear, and hardness tests. The machine applies a progressively increasing load on the test specimen, and the deformation of the specimen is measured and recorded.

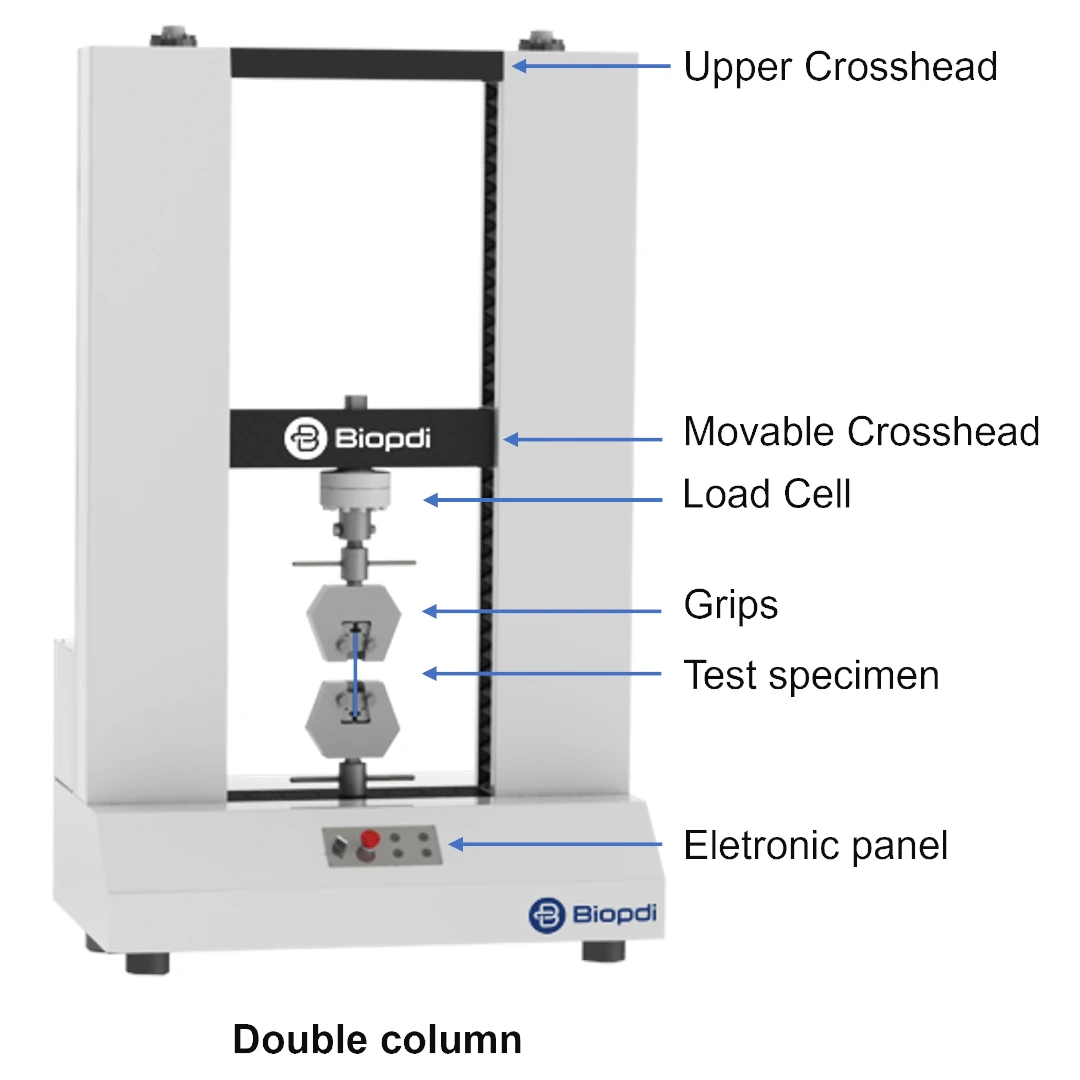

The UTM consists of two main parts: the load frame that applies the load and the control system that controls the load application and records the test data. The load frame has two crossheads; one is adjusted for the length of the specimen and the other is driven to apply tension or compression to the specimen.

The control system can be a simple dial and knob system, or it can be computer-controlled with sophisticated software for test control, data acquisition, and analysis. The test results are typically plotted as a stress-strain curve, which shows how the material responded to the applied load.

In summary, a Universal Testing Machine is a critical instrument in the materials testing field, providing valuable data on the mechanical properties and behavior of materials under different load conditions.

What is the importance of Universal Testing Machine?

The Universal Testing Machine (UTM) holds immense importance in the fields of material science and engineering due to its multifaceted applications and the critical insights it provides into the mechanical properties of materials. Here are some key reasons why the UTM is considered essential:

- Versatility: The UTM can perform a multitude of tests such as tensile, compression, bending, shear, and many more. This versatility allows it to test a wide range of materials, including metals, plastics, composites, and even fabrics, under different conditions.

- Material Selection: By understanding the mechanical properties of a material, engineers can predict how it will behave under different conditions and choose the best material for a specific application. This is crucial in industries such as construction, automotive, aerospace, and many more where the right material choice can significantly impact the performance, safety, and longevity of the product.

- Quality Control: UTMs are often used in quality control and assurance processes. They help ensure that materials and products meet the required standards and specifications. Any deviations in the expected mechanical properties can indicate issues with the manufacturing process, allowing for timely corrective actions.

- Research and Development: In the realm of research and development, UTMs are invaluable. They allow scientists and engineers to test and analyze new materials or improvements to existing ones. The data gathered can lead to the development of innovative materials with superior properties.

- Failure Analysis: UTMs can also be used to understand the cause of material or product failures. By replicating the conditions leading to failure, analysts can identify the root cause and make necessary changes to the design or material selection to prevent future occurrences.

The Universal Testing Machine holds a vital role in the fields of material science and engineering. Its capability to offer a comprehensive understanding of a material’s mechanical properties is crucial in driving technological advancement, ensuring quality, and promoting safety and reliability in numerous industries.

Universal testing machines are used to conduct tests on a wide range of materials, spanning from metals and concrete to rubber and fabrics. They can be utilized with final products, prototypes, or specimens. Typically, manufacturers of universal testing machines also provide specific specimens to facilitate the execution and standardization of tests.

That’s why universal testing machines are now commonly found in various sectors, such as metal-mechanics, civil construction, medicine, automotive, clothing, furniture, and many more.

What are the advantages of using a Universal Testing Machine?

The Universal Testing Machine (UTM) offers a host of advantages that make it a vital tool in the fields of material science and engineering. Here are some of the key benefits of using a UTM:

- Versatility: One of the primary advantages of a UTM is its versatility. It can perform a wide range of tests, including tensile, compression, bending, shear, and more. This allows for comprehensive testing of materials under different conditions using a single machine.

- Accuracy and Precision: UTMs are designed to provide highly accurate and precise measurements of a material’s mechanical properties. This ensures reliable data that can be used for critical decisions in material selection, product design, and quality control.

- Adaptable to Various Materials: UTMs can test a wide variety of materials, from metals and plastics to composites and ceramics, and even soft materials like rubber and fabrics. This makes them suitable for use in diverse industries.

- Standardized Testing: UTMs allow for standardized testing according to international and industry-specific standards. This ensures consistency in testing procedures and results, facilitating comparison of data across different materials, batches, or production processes.

- Detailed Analysis: UTMs not only provide raw data but also allow for detailed analysis of the material’s behavior under stress. This includes generating stress-strain curves, which provide insights into properties like elasticity, yield strength, ultimate tensile strength, and ductility.

- Cost-Effective: Despite their advanced capabilities, UTMs can be a cost-effective solution for material testing. By consolidating multiple testing capabilities into a single machine, they can save on the cost of purchasing, maintaining, and operating multiple single-function machines.

- Predictive Analysis: The data obtained from UTMs can be used for predictive analysis, helping engineers anticipate how materials will behave under different conditions. This can guide design decisions and help prevent material failure in real-world applications.

In summary, the Universal Testing Machine offers a combination of versatility, precision, and comprehensive analysis that makes it an invaluable tool in material testing. Its benefits extend to various aspects of material science and engineering, from research and development to quality control and failure analysis.

How does a Universal Testing Machine work?

A Universal Testing Machine (UTM) operates on a relatively straightforward principle, but its versatility allows it to conduct a wide range of tests to determine the mechanical properties of a material. Here’s a basic overview of how a UTM works:

- Sample Preparation: The first step involves preparing the sample to be tested. This could be a metal rod, a plastic sheet, a piece of fabric, or any other material. The sample is shaped and sized according to the requirements of the specific test to be performed.

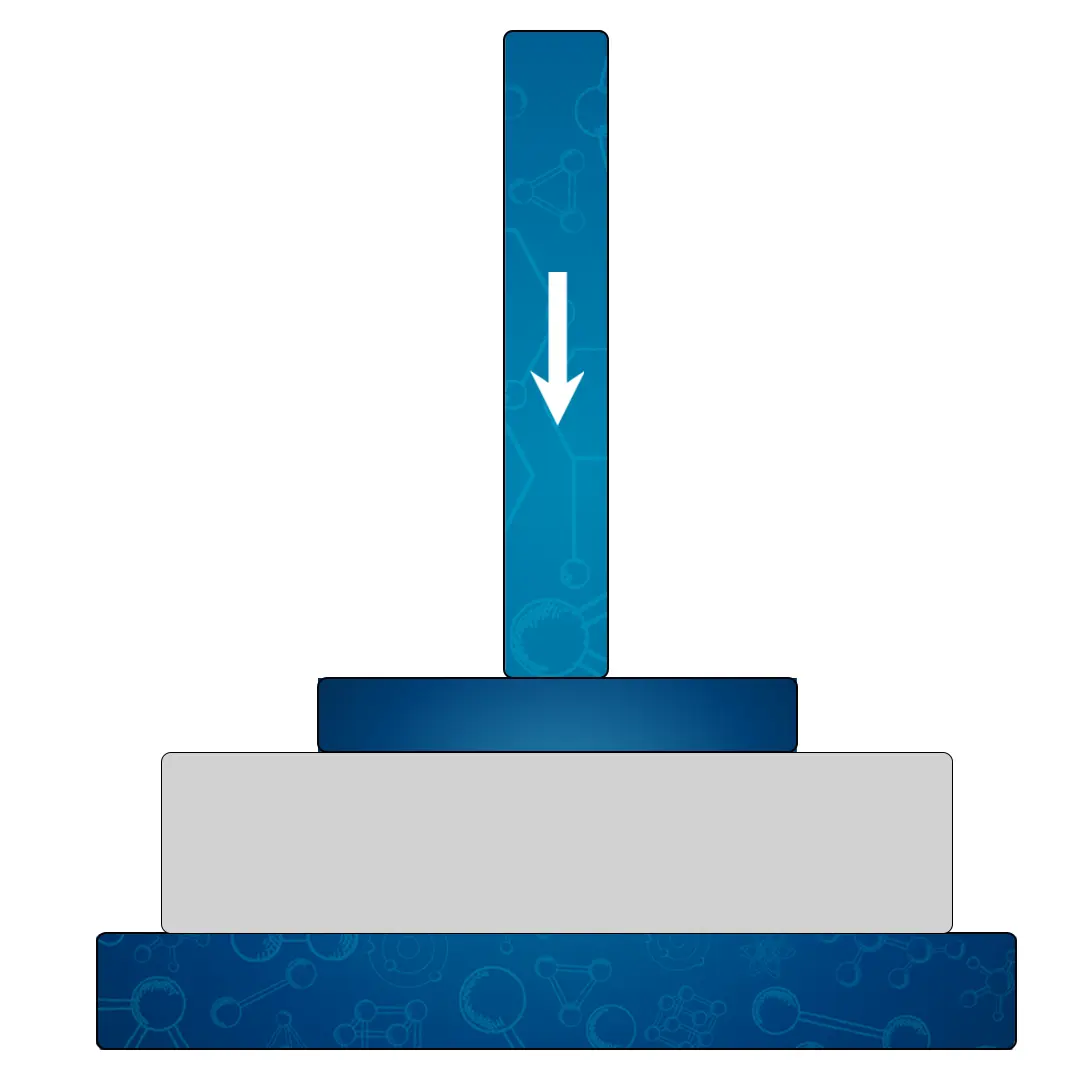

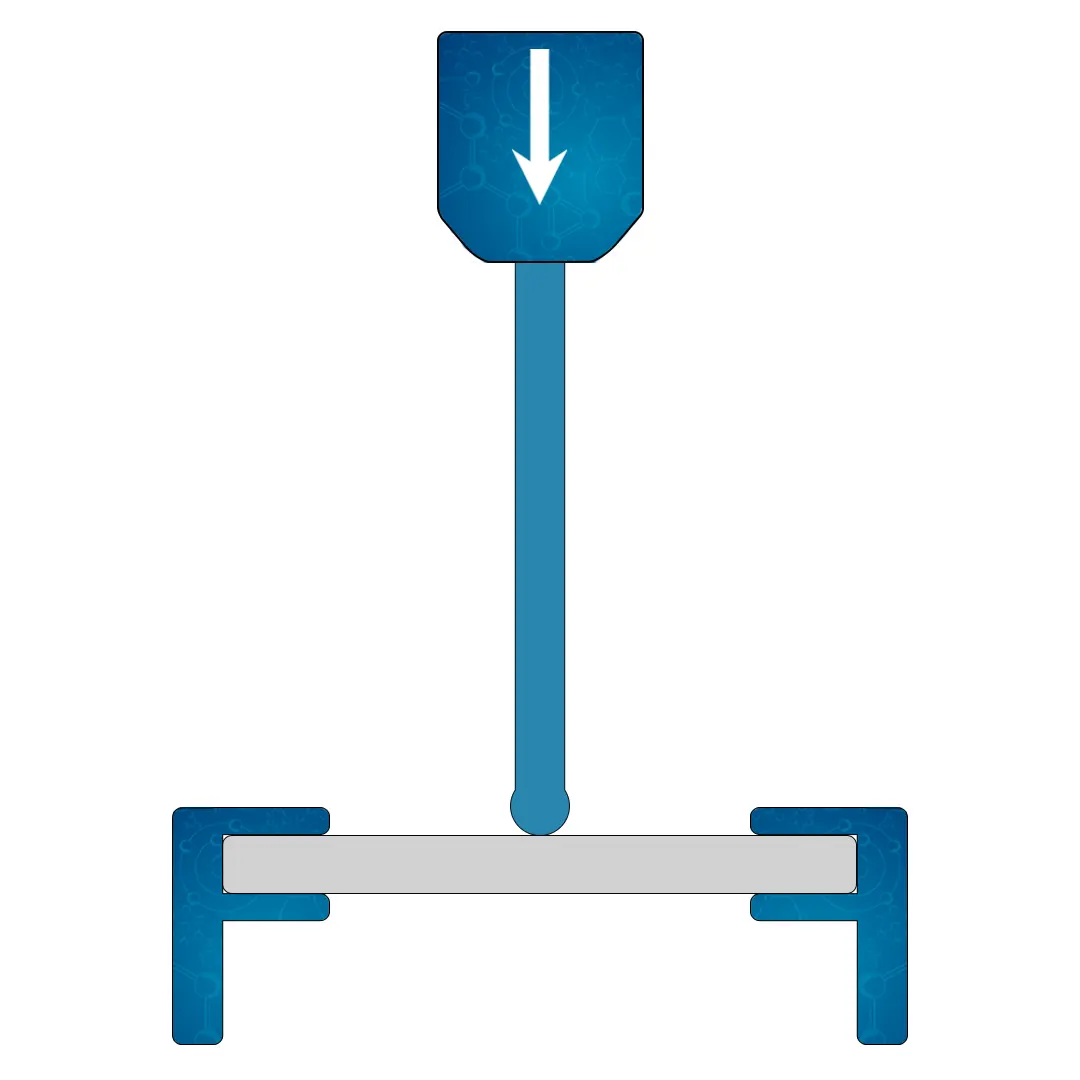

- Mounting the Sample: The prepared sample is then mounted onto the UTM. For tensile tests, the sample is gripped at both ends. For compression tests, the sample is placed between two plates. The setup varies depending on the type of test.

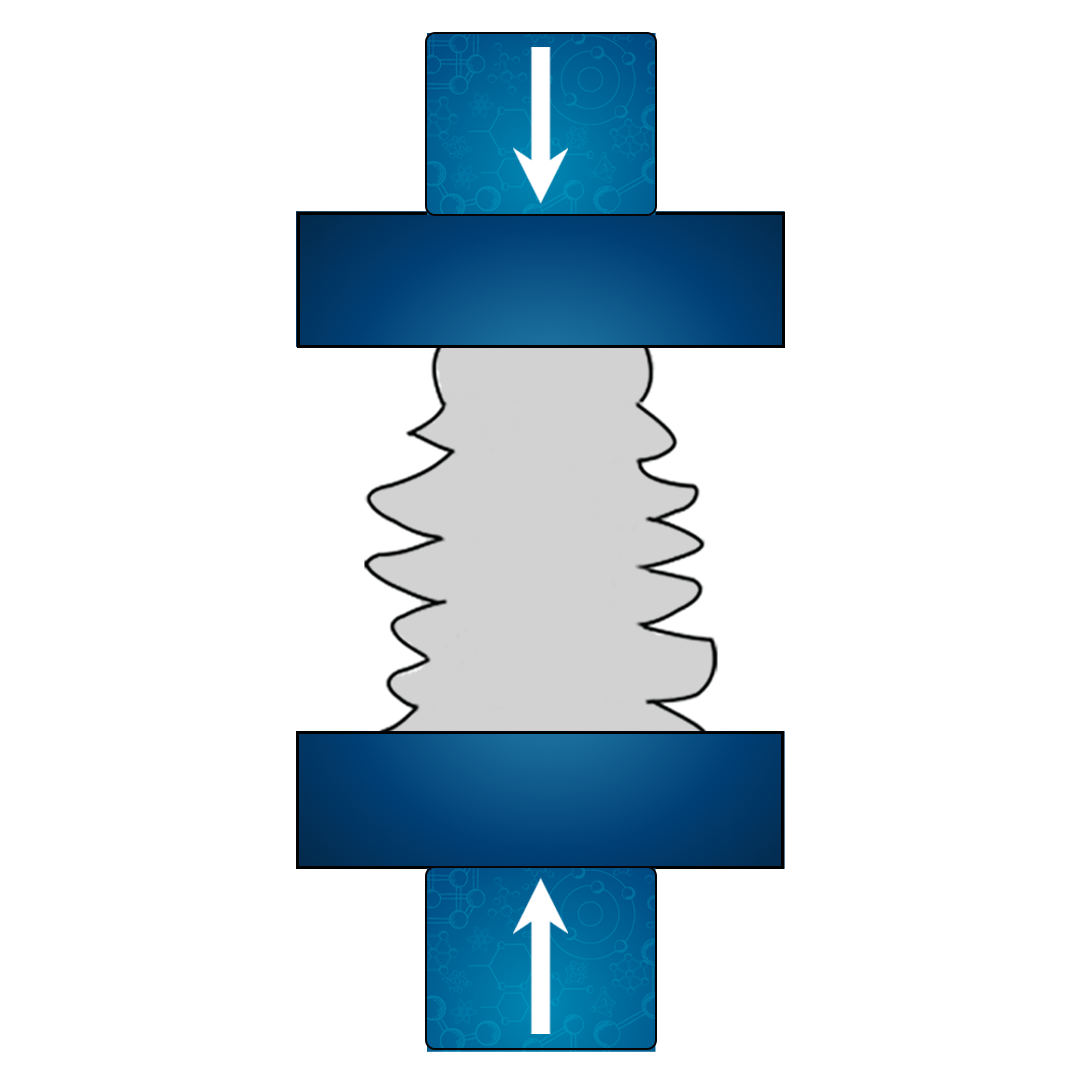

- Applying Force: Once the sample is secured, the UTM applies force to it. This force can be tensile (pulling apart), compressive (pushing together), or a shear force (sliding layers). The force is applied gradually and controlled precisely.

- Measuring Deformation: As the force is applied, the UTM measures the deformation of the sample. This is typically done using an extensometer or similar device that can track the changes in the sample’s dimensions.

- Data Collection and Analysis: The UTM records the applied force and the corresponding deformation of the sample. This data is used to calculate various mechanical properties of the material. For example, in a tensile test, the stress-strain curve can be plotted to determine the material’s elasticity, yield strength, ultimate tensile strength, and ductility.

- Result Interpretation: The results are then interpreted to understand the material’s behavior under the applied conditions. This information is crucial for material selection, design decisions, quality control, and failure analysis.

Universal Testing Machine works by applying a controlled force to a material and measuring how the material responds to that force. The data collected provides valuable insights into the material’s mechanical properties and behavior under different conditions.

Material testing

Material tests are used to determine the properties and characteristics of materials, components, structures, or any other type of product. Materials can be characterized by their physical and chemical properties.

Among the physical properties, the mechanical properties stand out. These properties describe how the materials react to applied forces or their resistance to external pressures. Determining the strength of materials is essential for dimensioning the parts and components of a product, minimizing waste and damage, and defining the degree of safety and quality of the materials used to prevent accidents and fatalities.

To determine the strength of a material, it is necessary to know its limit. This is achieved by subjecting either a manufactured object or a material that will undergo industrial processing to the expected real-life conditions or standard use. By observing the allowed limits, we can identify the point at which the object or material exhibits a fault. Material failures can be classified as either microscopic or macroscopic.

Microscopic material failure is defined in terms of crack initiation and propagation and, as the name implies, it is not always perceptible to the naked eye. Macroscopic material failure, on the other hand, is defined in terms of the capacity to support loads or store energy, which results in visible alterations to its structure (such as fractures or deformation). This can be assessed through different criteria such as S or T criteria, damage, or empirical observations.

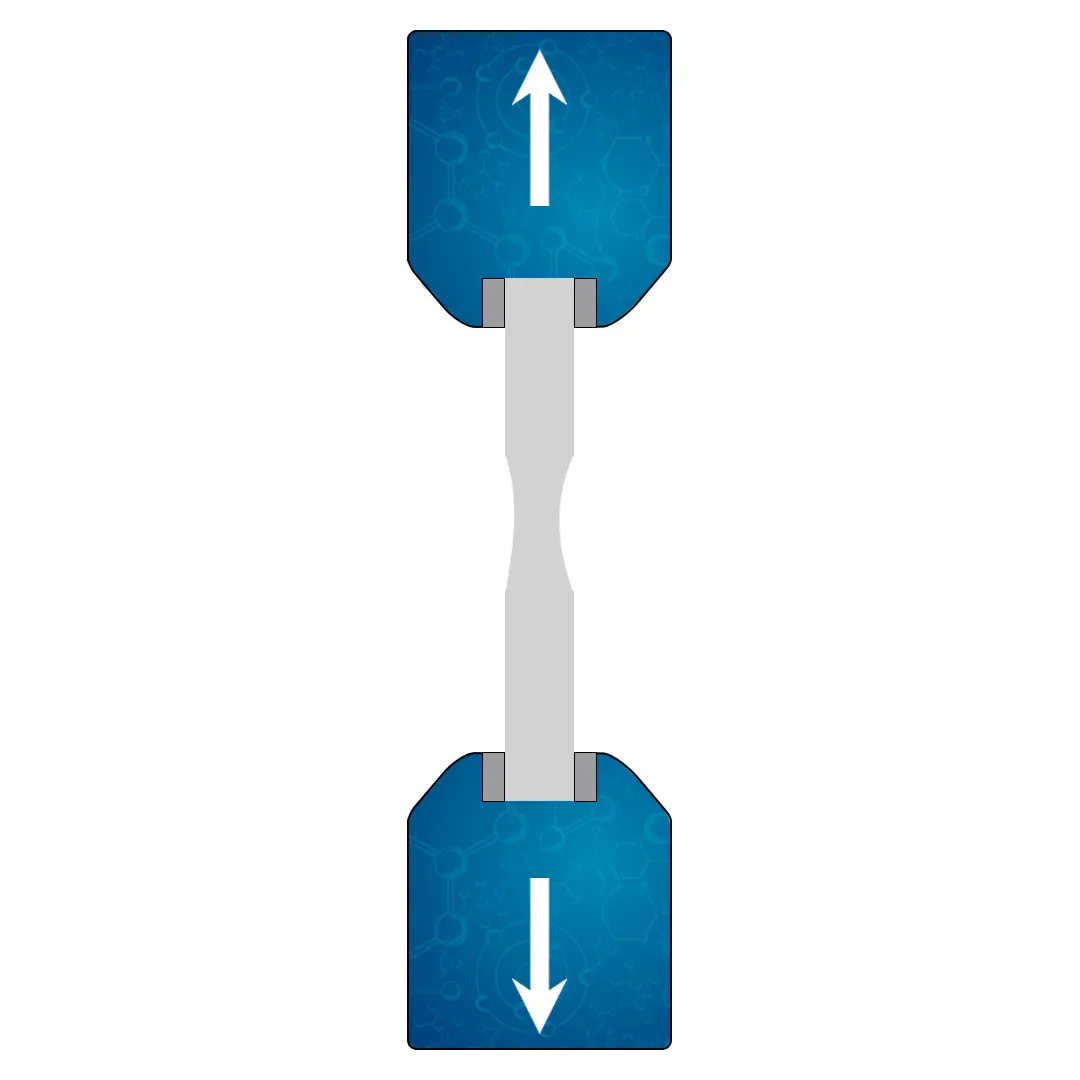

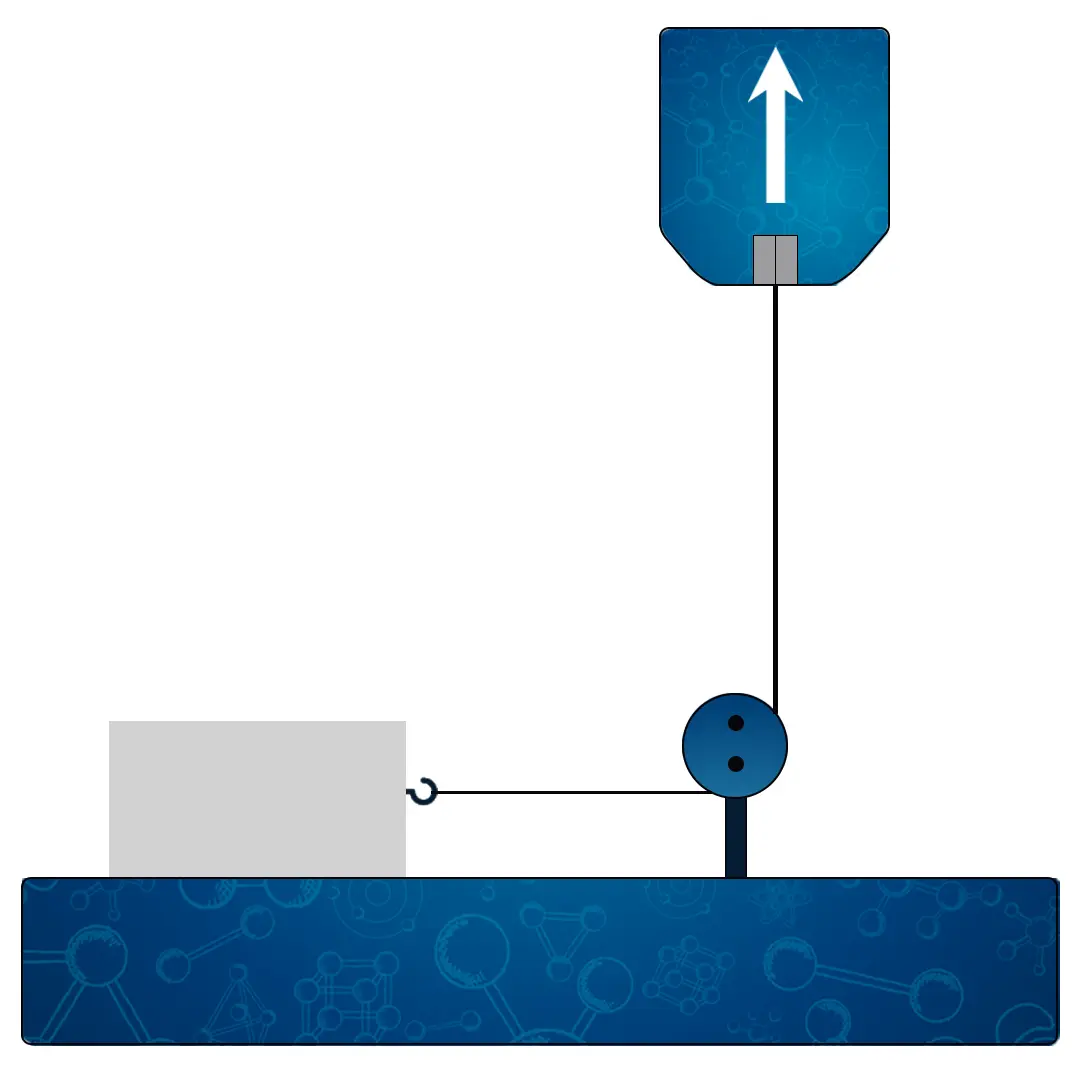

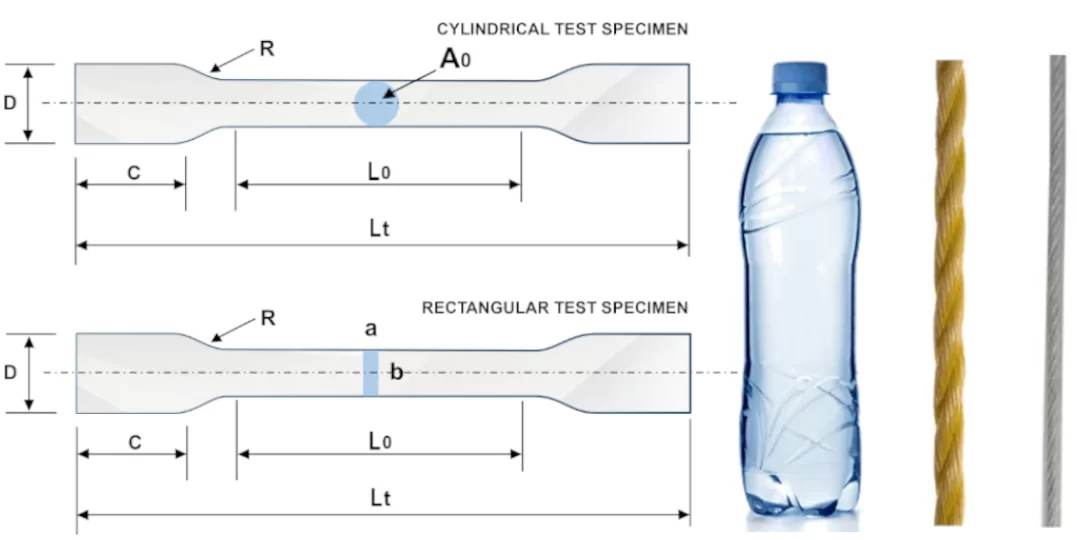

These tests can be conducted on the final product itself, on prototypes (preliminary versions of a product produced in small quantities), or on specimens (samples of the material to be tested). Some examples are shown in Figure 3.

The Universal Testing Machine is utilized to perform a variety of standardized tests on materials, components, structures, and various products. These tests help determine the properties and characteristics of the materials.

Figure 3: Functionality – leaving point A and arriving at point B

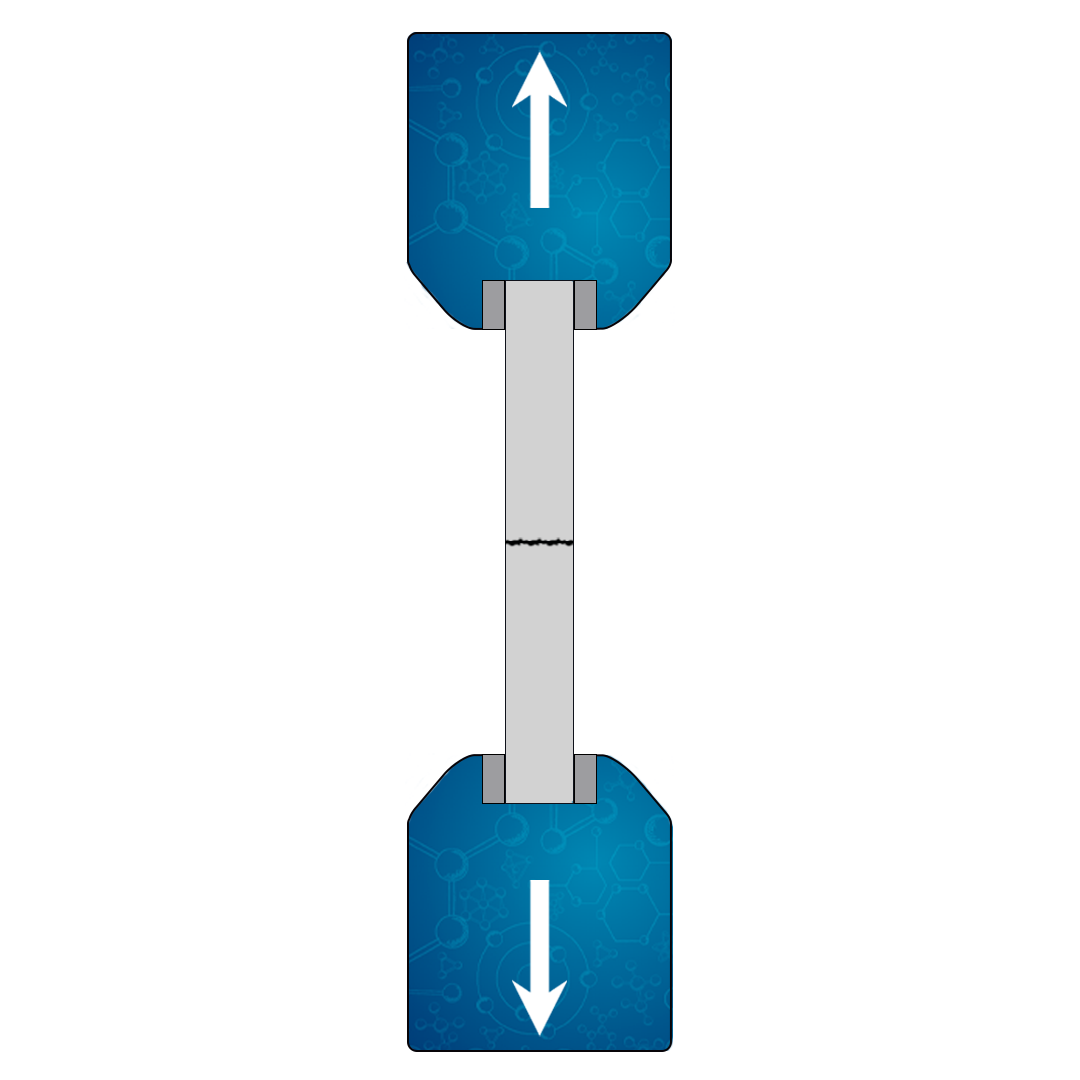

Characteristics of Universal Testing Machine

Most universal testing machines are modular. Its most common components are:

- Mechanical structure – consists of one or two columns that support the machine.

- Top crosspiece – Consists of a steel crosspiece that is located at the top of the machine frame.

- Lower crosspiece – Consists of a steel crosspiece that is located at the bottom of the machine frame.

- Movable Crosspiece – Consists of a movable crosspiece that moves up or down at a constant speed to apply force.

- Load cells – a force transducer or any other means of measuring the load. It usually requires periodic calibration.

- Claws and actuators – They are used to fix specimens (specimens) or products for the test.

- Extensometer – Device for measuring the extent or deformation.

- Software – Device for outputting results – the way results are made available. Most modern machines also offer additional software processing and calculations.

- Conditioning – control of certain test conditions (temperature, humidity, pressure, etc.). It is usually external to the machine, such as a controlled conditions room or a chamber into which the machine (or the test specimen) is placed.

Figure 4 – Characteristics of the Universal Testing Machine.

Models of Universal Testing Machine

The Universal Testing Machine models can be classified as to the load generation mechanism (Hydraulic Load Generation and Electromechanical Load Generation); Velocity of tests (Static testing and Dynamic testing); Structure of machine (Single column and Double column); Accommodation of machine (Portable, Table moldel, Floor Model) and Load capacity ( 500 N until 3 MN ).

Load generations mechanism

Universal Testing Machines (UTMs) can generate loads using different systems, each with its own advantages and considerations. Here are some additional thoughts on hydraulic and electromechanical systems:

Hydraulic Load Generation

Hydraulic UTMs use a hydraulic unit to apply load on the samples. This system is particularly advantageous when large loads are required, as hydraulic systems can generate high forces. This makes hydraulic UTMs ideal for testing materials like metals, concrete, and other high-strength materials.

However, one of the potential drawbacks of hydraulic systems is the difficulty in controlling the speed and displacement of the moving crosshead. While modern hydraulic systems have improved in this aspect, they may still not provide the same level of precision as electromechanical systems, particularly at very low speeds or small displacements.

Additionally, hydraulic systems may require more maintenance than electromechanical systems, as they involve more moving parts and fluids that can leak or degrade over time.

Electromechanical Load Generation

Electromechanical UTMs use a servomotor to apply a controlled and precise load on the samples. The main advantage of this system is the high level of control it provides over the speed and displacement of the moving crosshead. This allows for very precise control of the testing conditions, making electromechanical UTMs suitable for tests that require a high degree of accuracy and repeatability.

Velocity of tests

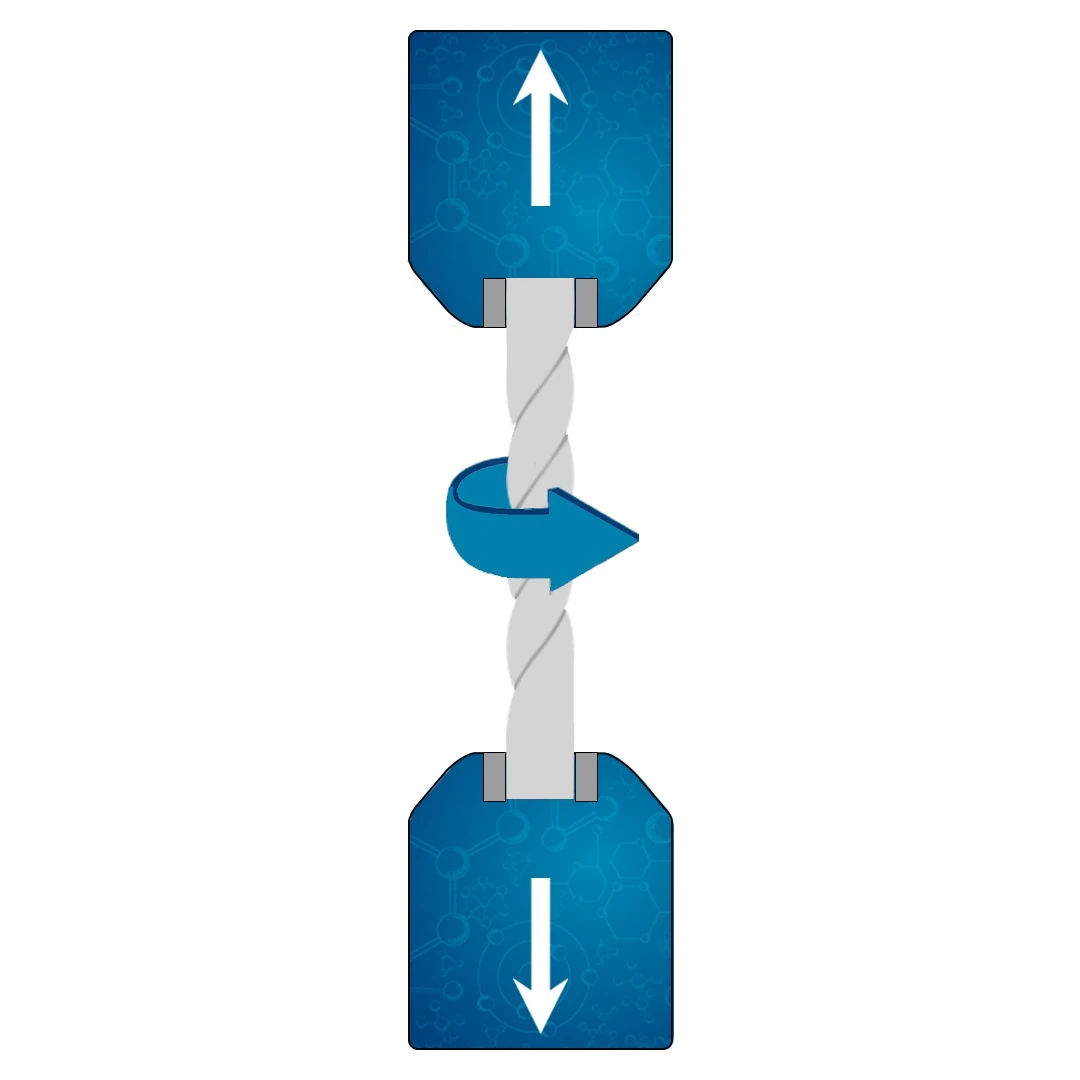

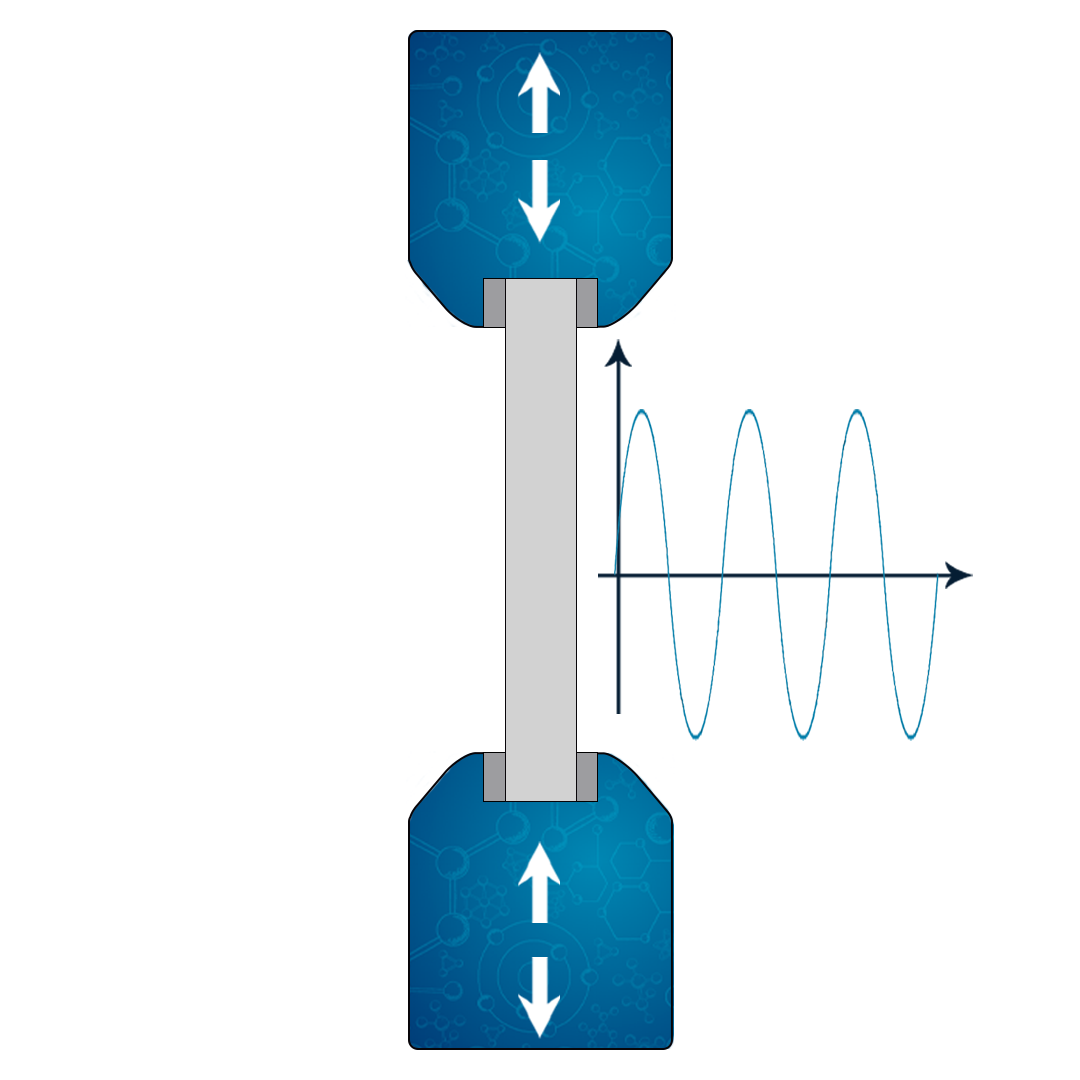

Static and dynamic testing are two fundamental types of mechanical testing that can be performed on a Universal Testing Machine (UTM). Both types of testing provide valuable information about a material’s mechanical properties, but they do so under different conditions and with different methods.

Static Testing:

Static testing, as the name suggests, involves applying a slowly varying or constant load to a material and observing its response. The rate of load application is slow enough that the material’s strain rate is essentially zero. This allows the material to reach equilibrium at each point, meaning the internal stress distribution stabilizes before the next increment of load is applied.

In a UTM, static tests are typically used to determine properties such as tensile strength, compressive strength, elastic modulus, yield strength, and elongation. These tests provide a stress-strain curve, which gives a comprehensive view of a material’s behavior under static loading conditions.

Static testing is crucial in many applications where materials are subjected to slow or constant loads, such as building structures, bridges, or any application where long-term load bearing is required.

Dynamic Testing:

Dynamic testing, on the other hand, involves applying a rapidly varying load to a material. The load can be sinusoidal, random, or shock, and the material does not have time to reach equilibrium at each point. This means the material’s response can depend not only on the current load but also on the history of the load.

In a UTM, dynamic tests can be used to determine properties such as fatigue strength, damping characteristics, and dynamic modulus. These tests can provide a hysteresis loop, which shows the energy dissipation in each cycle of loading and unloading.

Dynamic testing is important in applications where materials are subjected to fluctuating loads or impacts, such as in vehicles, aircraft, or any machinery with moving parts. It’s also crucial for understanding the fatigue behavior of materials, which can lead to failure after many cycles of loading, even if each individual load is well below the material’s static strength.

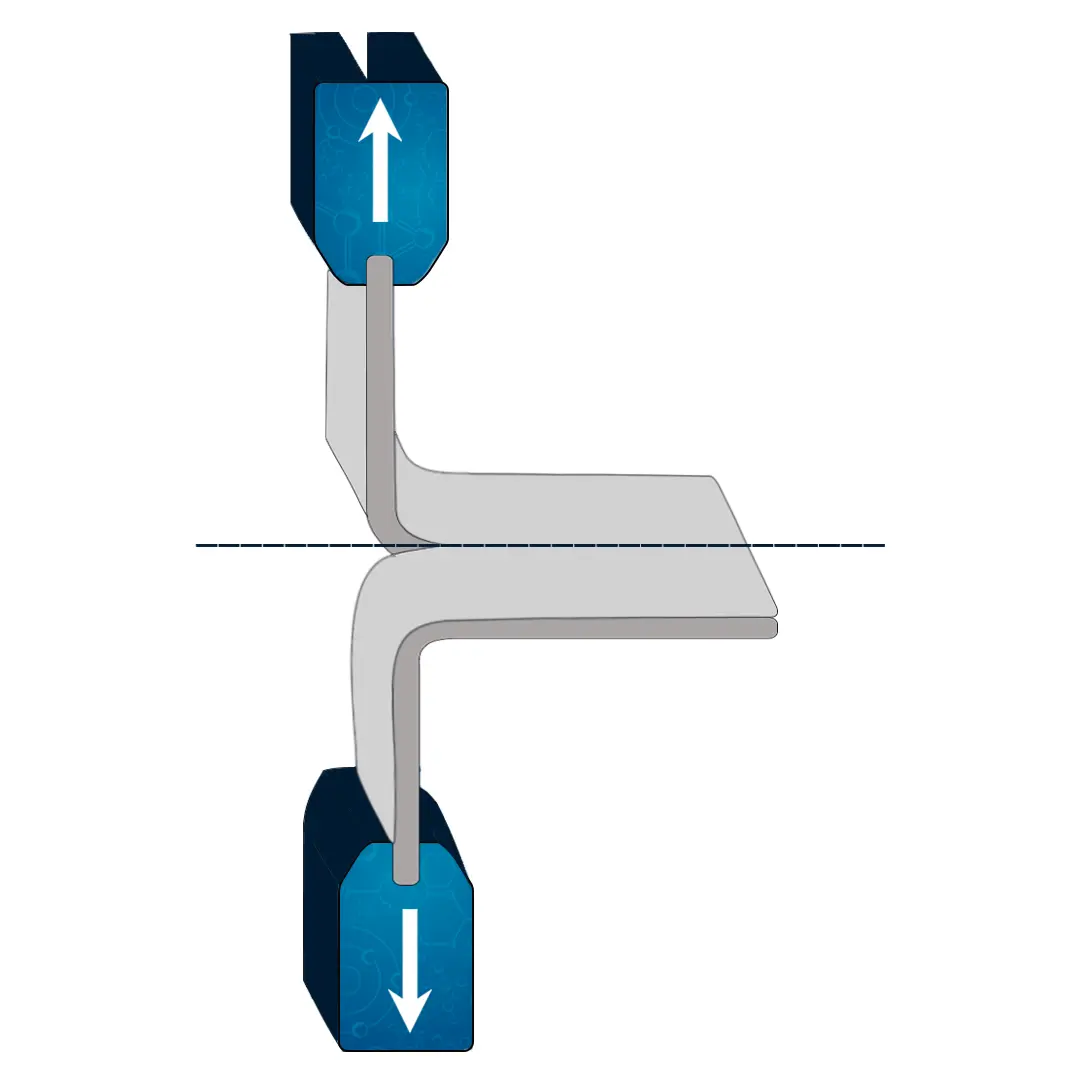

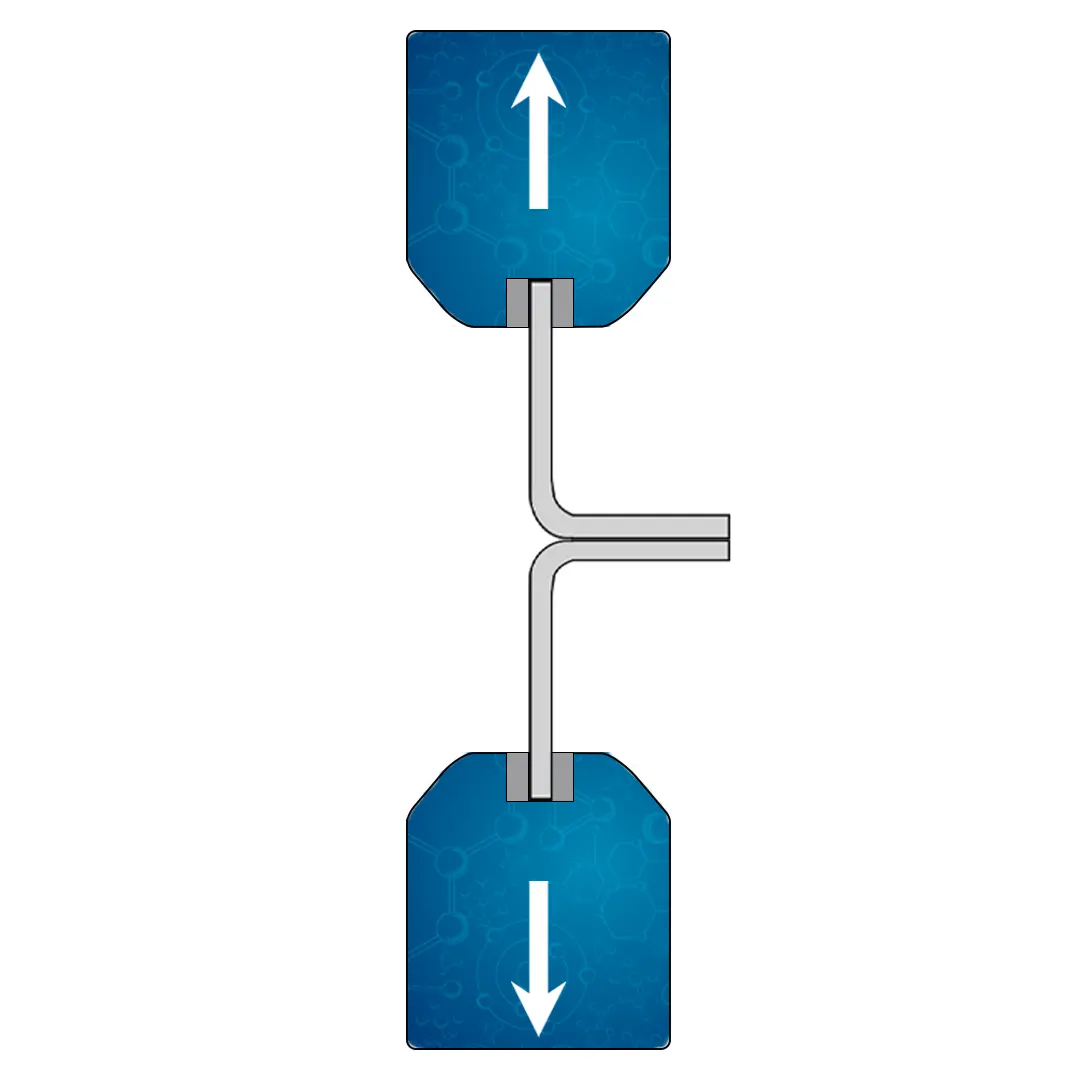

Structure of machine

The structure of a Universal Testing Machine (UTM) is indeed a critical aspect of its design, as it directly impacts the machine’s load capacity and the size of the samples that can be tested. Here are some additional considerations about single-column and double-column structures:

Single-Column Structure

A single-column UTM is typically used for tests that require lower load capacities, often up to 1000 kgf. These machines are generally more compact, making them suitable for laboratories or facilities with limited space.

Single-column UTMs are ideal for testing smaller samples and are often used for materials like plastics, textiles, or small components. However, due to their design, they may not provide the same level of stability and rigidity as double-column machines, especially when testing at the higher end of their load capacity.

Double-Column Structure

A double-column UTM is designed for tests that require higher load capacities, typically greater than 500 kgf. The double-column design provides greater stability and rigidity, allowing the machine to accurately apply and measure high forces.

Double-column UTMs can accommodate larger samples, making them suitable for testing materials like metals, composites, or large components. However, they are larger and heavier than single-column machines, requiring more space in the laboratory or testing facility.

Figure 5 – Universal Testing Machine – Single column and double column.

Accommodation of machine

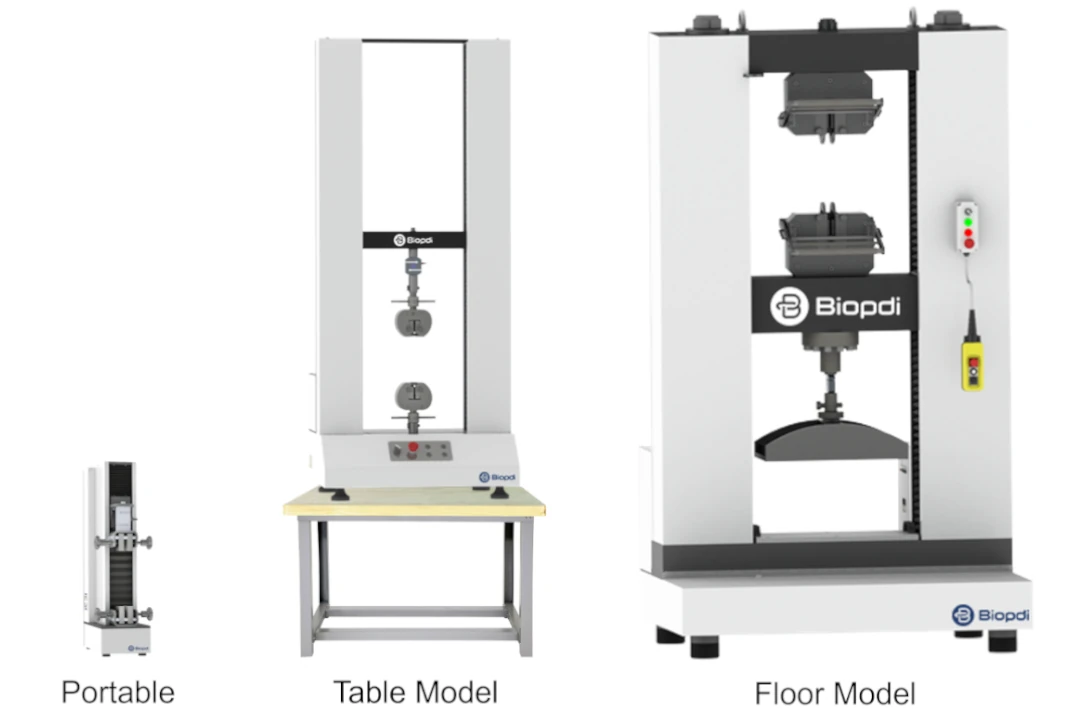

Universal Testing Machines come in three main varieties: Portable, Table Model, and Floor Models.

- Portable Universal Testing Machines: These are compact and lightweight, designed for mobility. You can take them wherever you need to perform tests, making them highly versatile.

- Table moldel Universal Testing Machines: These are designed to sit on a sturdy table or bench. They are larger and heavier than portable units but offer more testing capabilities.

- Floor Model Universal Testing Machines: These are large, standalone units that sit directly on the floor. They’re self-supporting, meaning they don’t need a table or bench. These models typically offer the most comprehensive testing abilities due to their size and stability.

Figure 6 – Universal Testing Machine: Portable, Table Model, and Floor Models

Load capacity

The universal testing machine can be classified with respect to its load capacity and which can be found in a wide range from 50 kgf to 300,000 kgf, the main models are:

Universal Testing Machine – 05 kN (50kgf)

Universal Testing Machine – 2 kN (200kgf)

Universal Testing Machine – 5 kN (500kgf)

Universal Testing Machine – 10 kN (1.000kgf)

Universal Testing Machine – 20 kN (2.000kgf)

Universal Testing Machine – 30 kN (3.000kgf)

Universal Testing Machine – 50 kN (5.000kgf)

Universal Testing Machine – 100 kN (10.000kgf)

Universal Testing Machine – 200 kN (20.000kgf)

Universal Testing Machine – 300 kN (30.000kgf)

Universal Testing Machine – 600 kN (60.000kgf)

Universal Testing Machine – 1000 kN or 1 MN (100.000kgf)

Universal Testing Machine – 2000 kN or 2 MN (200.000kgf)

Universal Testing Machine – 3000 kN or 3 MN (300.000kgf)

For more capacities, please contact us.

Types of Tests Performed on the Universal Testing Machine

Universal testing machines play a crucial role in materials testing and research, allowing for an extensive array of destructive tests to be conducted with precision and accuracy. These sophisticated machines have the capability to subject various materials to rigorous examination, enabling scientists and engineers to gain invaluable insights into their mechanical properties and behavior.

Universal testing machines are extensively used to conduct a diverse range of destructive tests, including:

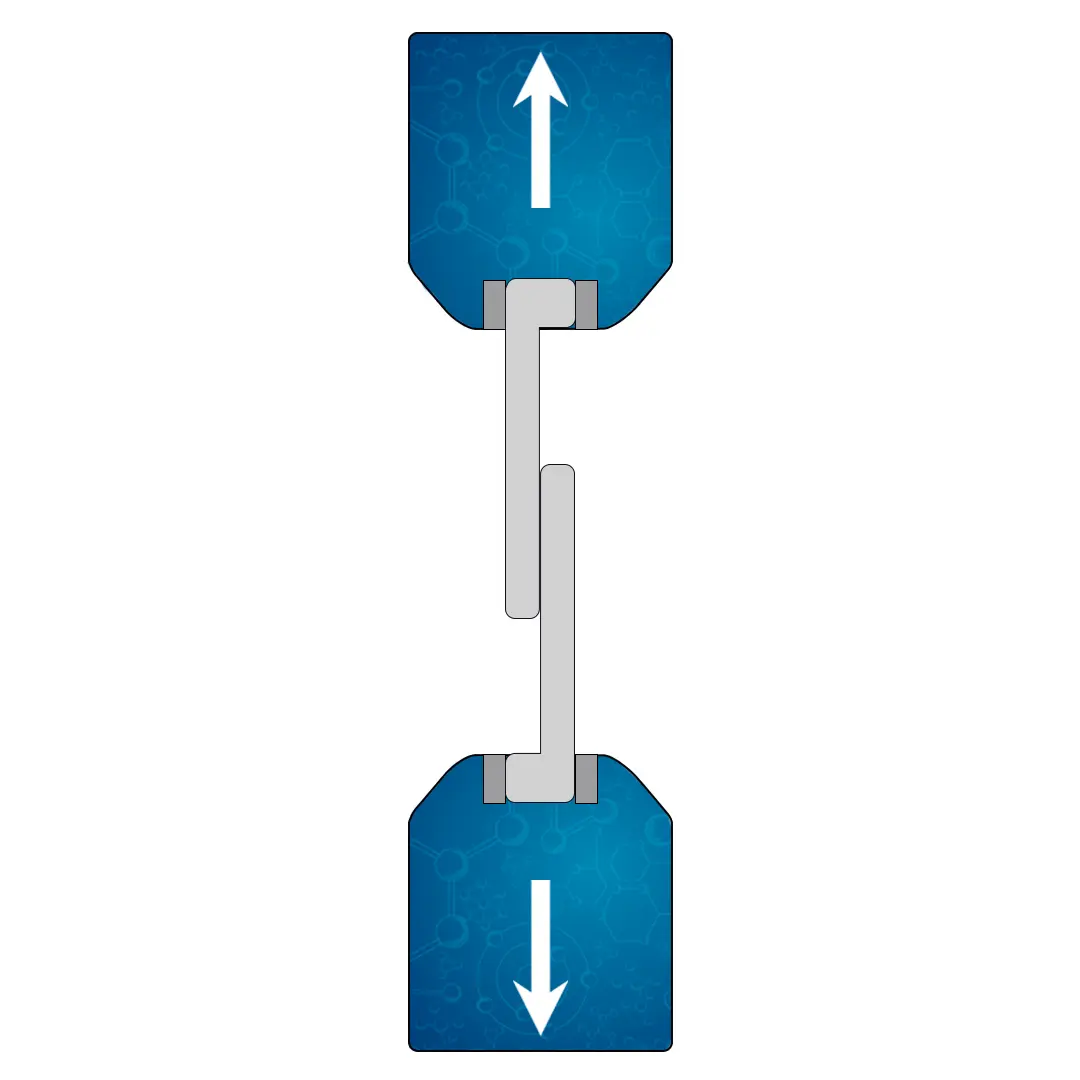

Tensile Test

Tensile testing is a crucial mechanical test used to evaluate the strength and ductility of materials. It involves applying a controlled force along the longitudinal axis of a sample until it fractures or undergoes permanent deformation. See more

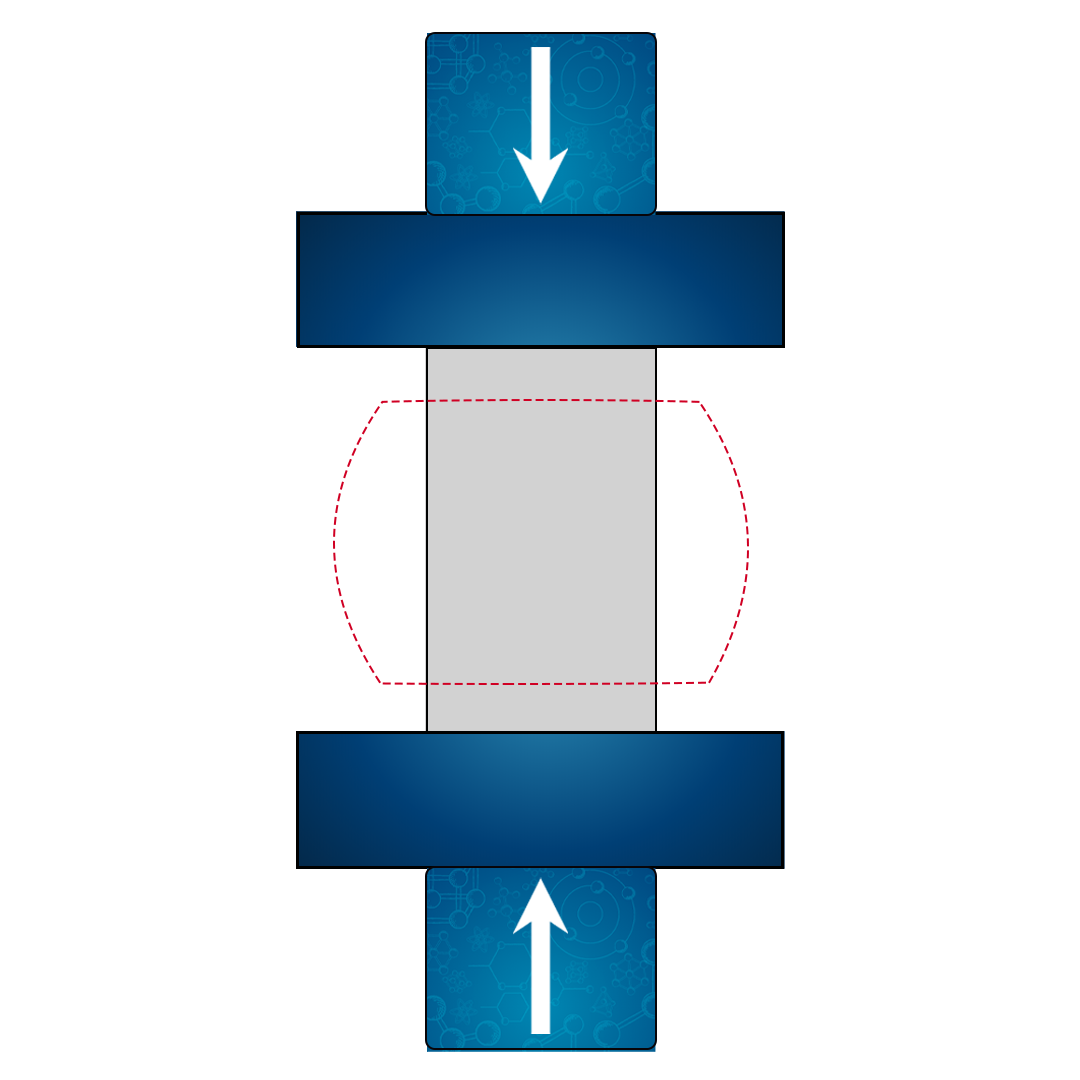

Compression Test

The compression testing is a fundamental evaluation method employed to assess a material’s ability to withstand compressive forces. During the test, a sample is subjected to axial loads, leading to its reduction in height.See more

Shear Test

Shear testing examines a material’s response to forces acting parallel to its surface. By applying a force that causes one part of the material to slide against another, the shear strength and deformation behavior can be evaluated. See more

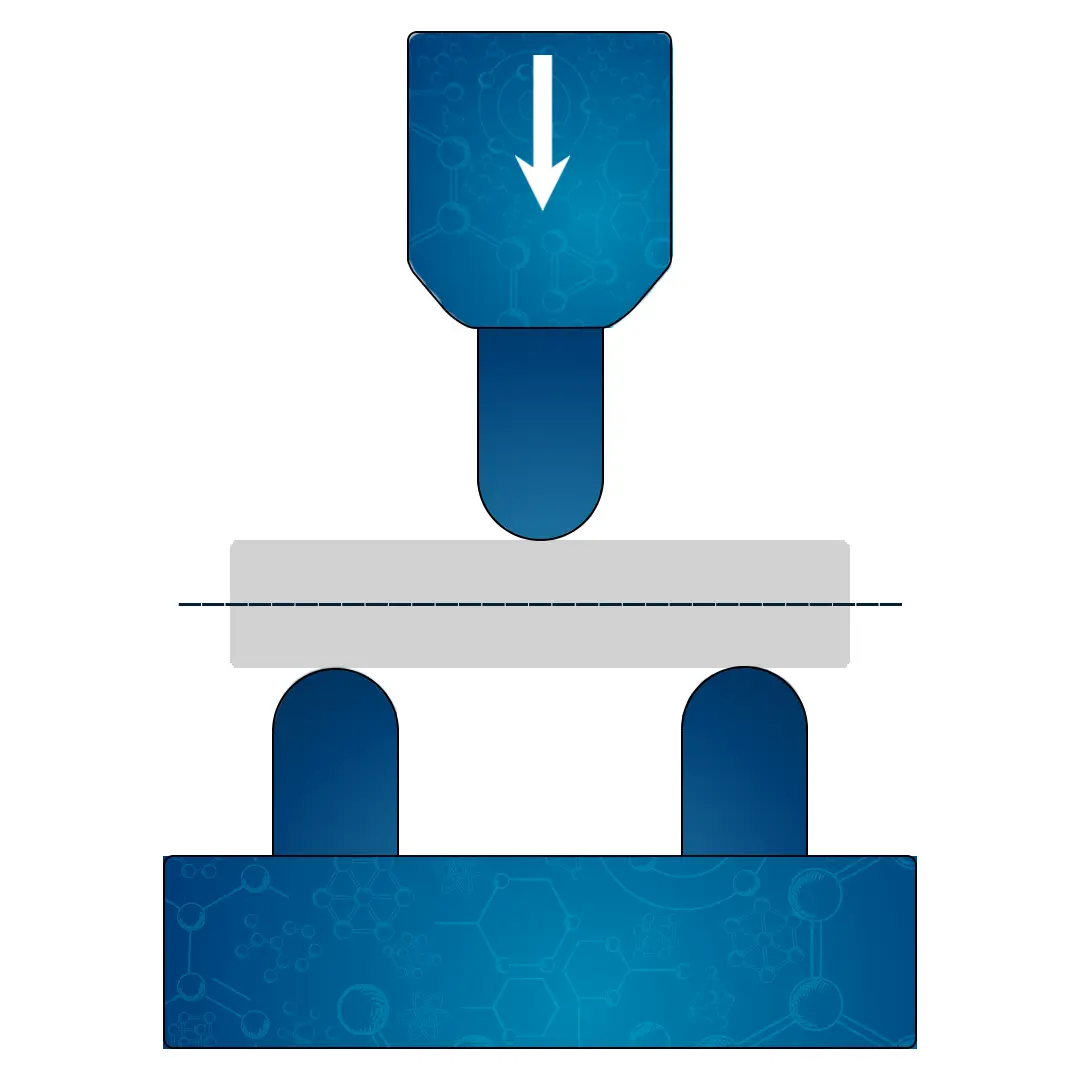

Bend Test

Bend testing is a mechanical test that determines a material’s flexibility and resistance to fracture under bending forces. It involves applying a load to a specimen over a specific span, inducing curvature until failure occurs.See more

Flexural Test

Flexural testing, also known as the three-point bend test, is employed to measure a material’s resistance to bending or flexural stress. A sample is supported at two points while a load is applied at the midpoint, causing deflection. See more

Friciton Testing

The coefficient of friction testing measures the amount of resistance between two surfaces in contact when one moves relative to the other. It quantifies the frictional forces that affect material performance in various applications.See more

Tear Test

The tear test determines a material’s resistance to tearing forces, often encountered in applications involving thin films, fabrics, or flexible materials. This test enables engineers to evaluate tear strength and propagation resistance. See more

Peel Test

Peel testing evaluates the strength of adhesion between two materials, typically an adhesive and a substrate. The test involves separating the materials at a specific angle and speed to measure the peel force required for detachment. See more

Indentation test

Indentation Force Deflection (IFD) is a measure used particularly in the field of material science and engineering to characterize the cushioning or compressive properties of a material, especially foams and soft polymers. See more

Fracture Test

Fracture toughness is a material’s ability to resist crack propagation. In engineering and materials science, understanding this property is vital for assessing a material’s suitability for applications where structural integrity is crucial. See more

Crush Test

A crush resistance test measures a material’s ability to resist deformation, particularly in terms of compressive force. This test is often used in the packaging industry to determine how much weight a container can bear before crushing. See more

Axial Torsion Test

Axial torsion test examines a material’s behavior when subjected to simultaneous axial and torsional loads. This test to study shear stress, shear strain, and ultimate strength characteristics, essential in designing components subjected. See more

Standards for universal testing machine

It is essential that every part, material, or product be tested according to pre-established methods. Typically, these methods are published in technical standards (such as NBR ABNT, ISO, DIN, ASTM, among others), which are widely recognized for ensuring universal consistency in the preparation, handling, measurement methods, analyses, calculations, and conditions of sample use. These standards also define and specify the specimens required for testing each material and characteristic.

There are numerous standards, both ISO and ASTM, that outline the procedures for conducting tensile tests on various materials. Here are the main standards:

ISO Standards:

- ISO 37:2017 – Rubber, vulcanized or thermoplastic – Determination of tensile stress-strain properties

- ISO 527-1:2019 – Plastics – Determination of tensile properties – Part 1: General principles

- ISO 527-2:2012 – Plastics – Determination of tensile properties – Part 2: Test conditions for moulding and extrusion plastics

- ISO 527-3:2018 – Plastics – Determination of tensile properties – Part 3: Test conditions for films and sheets

- ISO 527-4:1997 – Plastics – Determination of tensile properties – Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites

- ISO 527-5:2009 – Plastics – Determination of tensile properties – Part 5: Test conditions for unidirectional fibre-reinforced plastic composites

- ISO 6892-1:2019 – Metallic materials – Tensile testing – Part 1: Method of test at room temperature

- ISO 6892-2:2011 – Metallic materials – Tensile testing – Part 2: Method of test at elevated temperature

- ISO 6892-3:2015 – Metallic materials – Tensile testing – Part 3: Method of test at low temperature

- ISO 6892-4:2020 – Metallic materials – Tensile testing – Part 4: Method of test in liquid helium

- ISO 10113:2020 – Metallic materials – Sheet and strip – Determination of plastic strain ratio

- ISO 10275:2007 – Metallic materials – Sheet and strip – Determination of tensile strain hardening exponent

- ISO 15630-1:2019 – Steel for the reinforcement and prestressing of concrete – Test methods – Part 1: Reinforcing bars, wire rod and wire

- ISO 178:2019 – Plastics – Determination of flexural properties

- ISO 1920-10:2019 – Testing of concrete – Part 10: Determination of static modulus of elasticity in compression

- ISO 1920-12:2019 – Testing of concrete – Part 12: Determination of tensile strength of concrete surfaces

- ISO 6891:1984 – Aluminium oxide primarily used for the production of aluminium – Determination of specific surface area by nitrogen adsorption

- ISO 7500-1:2018 – Metallic materials – Calibration and verification of static uniaxial testing machines – Part 1: Tension/compression testing machines – Calibration and verification of the force-measuring system

- ISO 9513:2012 – Metallic materials – Calibration of extensometer systems used in uniaxial testing

- ISO 20601:2013 – Textiles – Determination of certain aromatic amines derived from azo colorants – Part 1: Detection of the use of certain azo colorants accessible with and without extracting the fibres

ASTM Standards:

- ASTM E8 / E8M – 16a: Standard Test Methods for Tension Testing of Metallic Materials

- ASTM D638 – 14: Standard Test Method for Tensile Properties of Plastics

- ASTM D412 – 16: Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

- ASTM D3039 / D3039M – 17: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials

- ASTM D882 – 18: Standard Test Method for Tensile Properties of Thin Plastic Sheeting

- ASTM D1708 – 18: Standard Test Method for Tensile Properties of Plastics by Use of Microtensile Specimens

- ASTM D2343 – 13: Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics

- ASTM D3552 – 17: Standard Test Method for Tensile Properties of Fiber Reinforced Metal Matrix Composites

- ASTM D3916 – 08(2016): Standard Test Method for Tensile Properties of Pultruded Glass-Fiber-Reinforced Plastic Rod

- ASTM D2105 – 01(2013): Standard Test Method for Longitudinal Tensile Properties of “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and Tube

- ASTM D2290 – 17: Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe

- ASTM D2256 / D2256M – 02(2018): Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method

- ASTM D76 / D76M – 11(2016): Standard Specification for Tensile Testing Machines for Textiles

- ASTM D885 / D885M – 10a(2014)e1: Standard Test Methods for Tire Cords, Tire Cord Fabrics, and Industrial Filament Yarns Made from Manufactured Organic-Base Fibers

- ASTM D3379 – 75(1989): Standard Test Method for Tensile Strength and Young’s Modulus for High-Modulus Single-Filament Materials

- ASTM D4595 – 11(2016): Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method

- ASTM D5035 – 11(2016): Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method)

- ASTM D6775 – 13: Standard Test Method for Breaking Strength and Elongation of Textile Webbing, Tape and Braided Material

- ASTM D7267 – 15: Standard Test Method for Edge Ravel Resistance of Finished Loop Pile, Pile Yarn Floor Covering

- ASTM D885 / D885M – 10a(2014)e1: Standard Test Methods for Tire Cords, Tire Cord Fabrics, and Industrial Filament Yarns Made from Manufactured Organic-Base Fibers

Videos about the universal testing machine

The world of Universal Testing Machines is ever-evolving, and our video series is your gateway to the latest innovations and advancements. Be awed by state-of-the-art features, smart automation, and cutting-edge software that redefine the boundaries of material testing. Discover how these advancements are driving efficiency, productivity, and ultimately, elevating the quality of products and materials worldwide.

Conclusion

The Universal Testing Machine, also known as a material testing machine, is an essential tool in the realm of materials science and engineering. It is capable of conducting a broad spectrum of mechanical tests on a diverse array of materials, making it a cornerstone in numerous industries.

The machine’s ability to perform tensile tests is particularly noteworthy, as it provides critical data on tensile strength, a fundamental property of materials. This information is vital in understanding how materials will behave when subjected to tension, which is crucial in many applications.

Moreover, the Universal Testing Machine’s capacity to function as a dynamic testing machine adds to its versatility. It can perform tests where the loads, stresses, or strains change with time, providing a more comprehensive understanding of a material’s behavior under real-world conditions.

The machine’s ability to conduct compression tests is another key feature. These tests provide essential data on how a material responds when subjected to compressive forces, which is crucial for materials used in construction and other fields where they must bear heavy loads.

In essence, the Universal Testing Machine is an indispensable instrument in the field of materials science. Its ability to perform a wide range of tests, including tensile and compression tests, makes it a vital tool for understanding the properties of materials, ensuring their safe and effective use in various applications.

FAQ

What is a Universal Testing Machine?

A Universal Testing Machine (UTM) is a device used to test the tensile and compressive strength of materials. It’s ‘universal’ because it can perform many standard tensile and compression tests on materials, components, and structures. The UTM operates by progressively applying load to the test specimen and measuring the corresponding deformation, allowing the stress-strain characteristics to be determined.

What tests can be done on a Universal Testing Machine?

A variety of tests can be performed using a UTM, including but not limited to: Tensile Strength Test: To determine how a material will react to forces being applied in tension; Compressive Strength Test: To find the maximum compressive load a material can bear before failure; Bend or Flexural Test: To measure a material’s flexibility or stiffness; Shear Test: To measure the shear strength of a material, which is the maximum force it can withstand before it breaks in response to opposing forces; Fatigue Test: To study how materials fail under cyclic loads or repeated stress; Creep Test: To measure how a material deforms over time under a constant load.

How accurate is a Universal Testing Machine?

The accuracy of a Universal Testing Machine can be very high, often within a small fraction of a percent. The exact accuracy can depend on various factors, including the quality of the machine, the calibration of the machine, and the conditions under which tests are performed.

What is the conclusion/results of the Universal Testing Machine?

A UTM provides valuable data about a material’s mechanical properties, including its strength, flexibility, and resistance to deformation. This information can be used to make informed decisions about the suitability of a material for a specific application, the need for material modifications, and the prediction of the material’s behavior under specific conditions.

What are the benefits of a Universal Testing Machine?

Some benefits of a UTM include: Versatility: It can conduct a wide range of tests, making it a highly versatile tool in materials testing; Precision: It can provide highly accurate and reliable data about a material’s mechanical properties; Customizable: Many UTMs can be fitted with different fixtures to accommodate a wide range of materials and test types; Efficient: The UTM is an efficient tool, allowing for quick adjustments and changes between different test types; Facilitates Informed Decision-Making: The data gathered from a UTM can aid in selecting the right materials for specific applications, improving product designs, and predicting the durability and longevity of materials under specified conditions.

What are the major components of a Universal Testing Machine?

The major components of a UTM typically include a load frame, a load cell to measure the force applied, extensometers or strain gauges to measure material deformation, grips or fixtures to hold the test specimen, and a control unit with software to control the test parameters and record data.

How do you operate a Universal Testing Machine?

Operating a UTM involves mounting the test specimen, selecting the appropriate fixtures, setting up the load cell and extensometer, setting the test parameters in the control software (like the rate of load application), and starting the test. It’s essential that the operator is trained and follows safety procedures, as incorrect usage could result in inaccurate data or even damage to the machine or test specimen.

Can a Universal Testing Machine perform tests on all types of materials?

A UTM is versatile and can test a wide range of materials, including metals, polymers, ceramics, composites, wood, and even some forms of concrete and cement. However, some materials or types of tests might require specialized fixtures or test setups.

How often should a Universal Testing Machine be calibrated?

The frequency of calibration depends on usage and the specific requirements of the testing procedures. However, as a general rule, many recommend annual calibration to ensure accurate and reliable results. Calibration should also be performed if the machine has been repaired or modified, if it has been moved, or if it has been used heavily or under unusual conditions.

What is the cost of a Universal Testing Machine?

The cost of a UTM can vary widely depending on its size, capacity, complexity, and the specific features it includes. Prices can range from a few thousand dollars for small, simple machines to hundreds of thousands of dollars for large, high-capacity machines with advanced features and capabilities.

Contact us

Phones:

+1 (781) 328 – 2010

sales@biopdi.com

Address:

2 Burlington Woods Dr, Burlington, Massachusetts, United States